Cleaning method and special cleaner for liquid storage cylinder of hydraulic shock absorber

A technology for hydraulic shock absorbers and liquid storage cylinders, which is applied to cleaning methods and appliances, chemical instruments and methods, and cleaning hollow objects, etc. It can solve the problems of high cleaning costs, large energy consumption, and affecting the viscosity of shock absorbing oil, etc., to achieve Low cleaning cost, high cleaning efficiency and strong carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] This embodiment is a fully manual model, which is provided with a dust brushing position, a dust suction position, a compressed gas source, a compressed gas pipeline containing a filter and connected to the compressed gas source, a negative pressure dust suction device, and a negative pressure dust suction device. Negative pressure pipeline connected to the device. Wherein, the negative pressure dust collection device is an industrial vacuum cleaner, and the compressed air source is an air compressor.

[0045] The dust brush position is provided with a brush rod, a brush head, a reciprocating mechanism, and a self-rotating drive mechanism, and the brush head is installed at one end of the brush rod; The relative axial movement is driven by the self-rotation drive mechanism to rotate relative to the axial direction of the brush rod. Specifically, the brush bar is a rack and is fixed on the handle through a dovetail sliding structure. The dovetail sliding mechanism inclu...

Embodiment 2

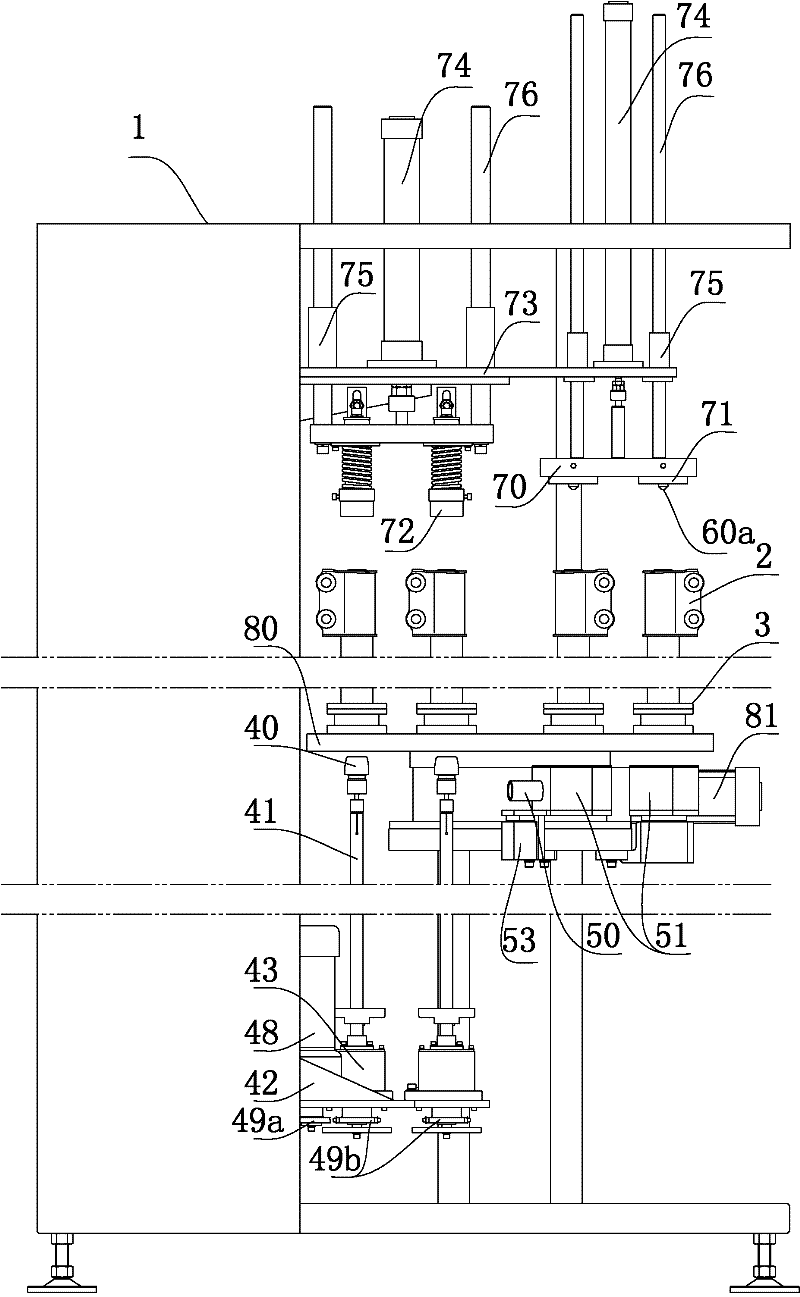

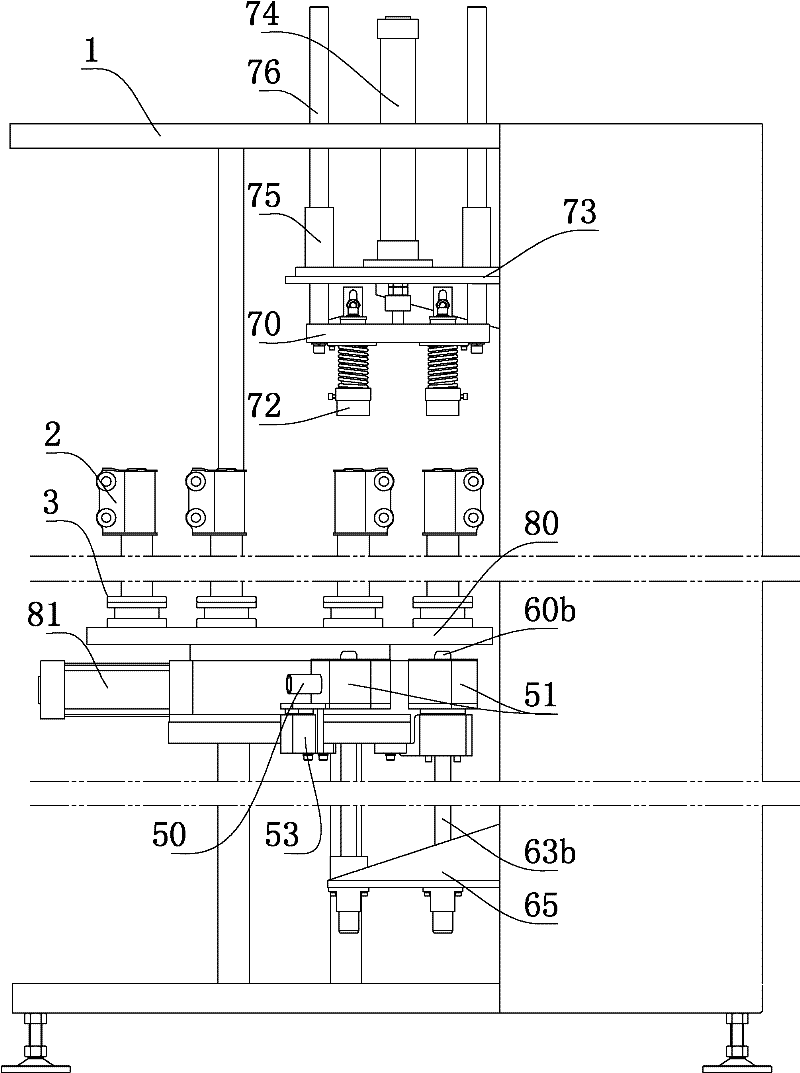

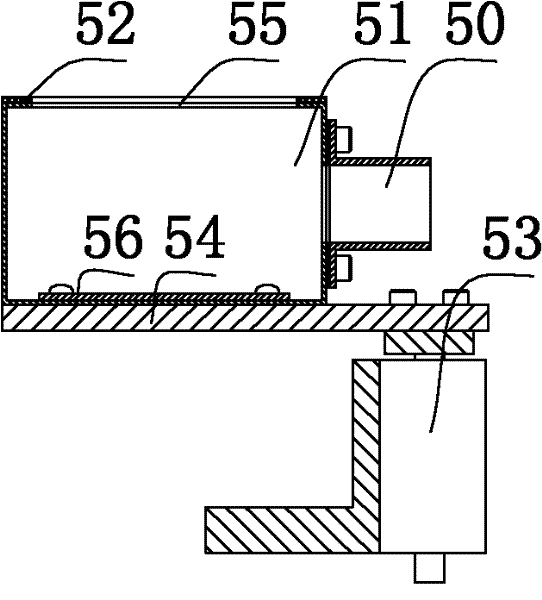

[0051] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 As shown, the cleaning machine of the hydraulic shock absorber liquid storage cylinder in this embodiment is a fully automatic model, and is provided with a dust brushing position, a dust collection position, a frame 1, a step-by-step transmission mechanism installed on the frame 1, a Group mounting base 3, compressed gas source, compressed gas pipeline containing a filter and connected to the compressed gas source, negative pressure dust collection device, and negative pressure pipeline connected to the negative pressure dust collection device. The negative pressure dust collection device is an industrial vacuum cleaner, and the compressed air source is an air compressor. The transmission mechanism is a turntable mechanism comprising a turntable 80, a mounting shaft, a stepping motor 81, and a turntable transmission mechanism. The turntable 80 is mounted on the frame 1 through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com