Method for preparing zinc oxalate with pearl luster and zinc oxide powder with pearl luster

A technology of zinc oxide powder and zinc oxalate, which is applied in carboxylate preparation, zinc oxide/zinc hydroxide, organic chemistry, etc., can solve the problems of no pearly luster and harsh conditions, and achieve excellent UV shielding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

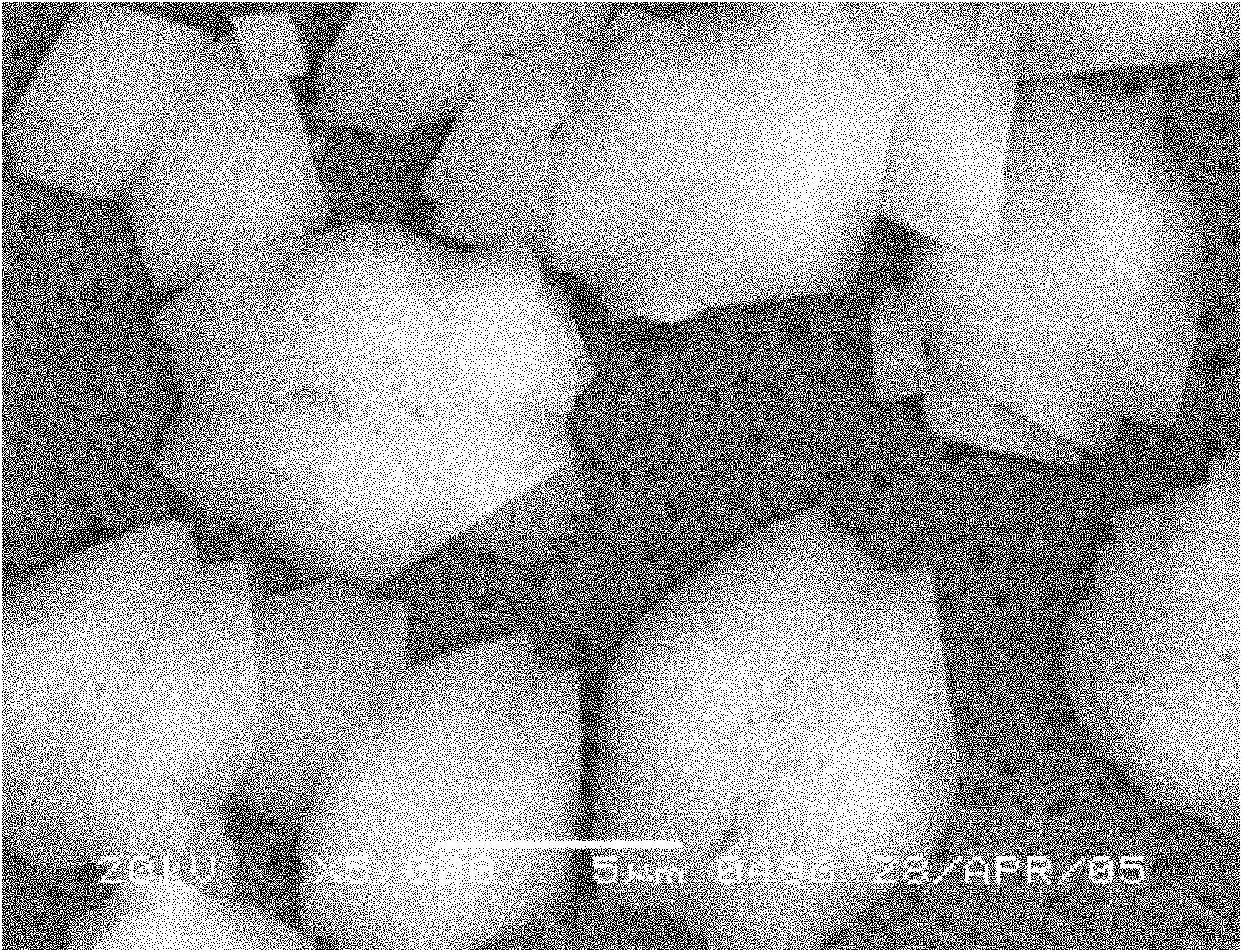

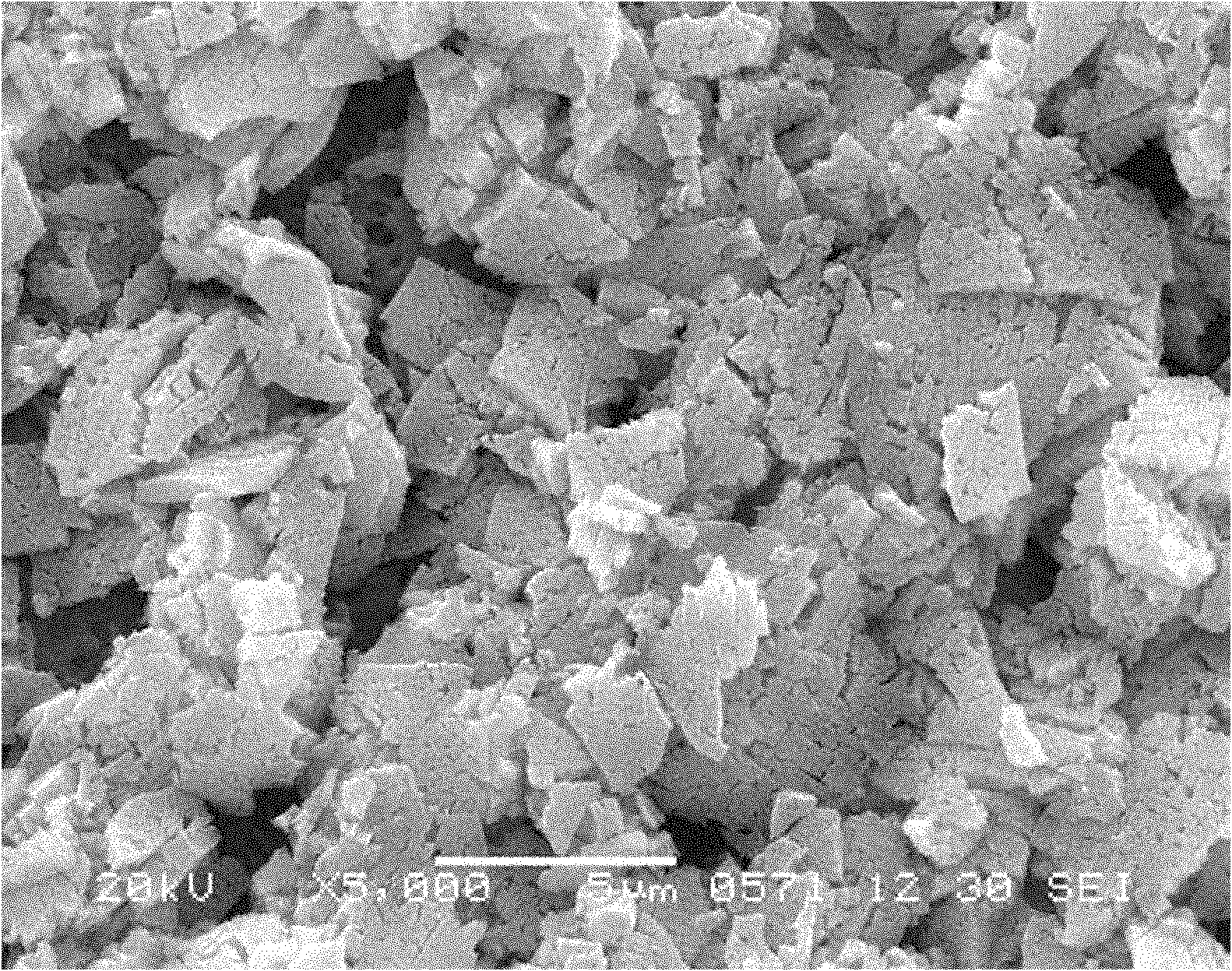

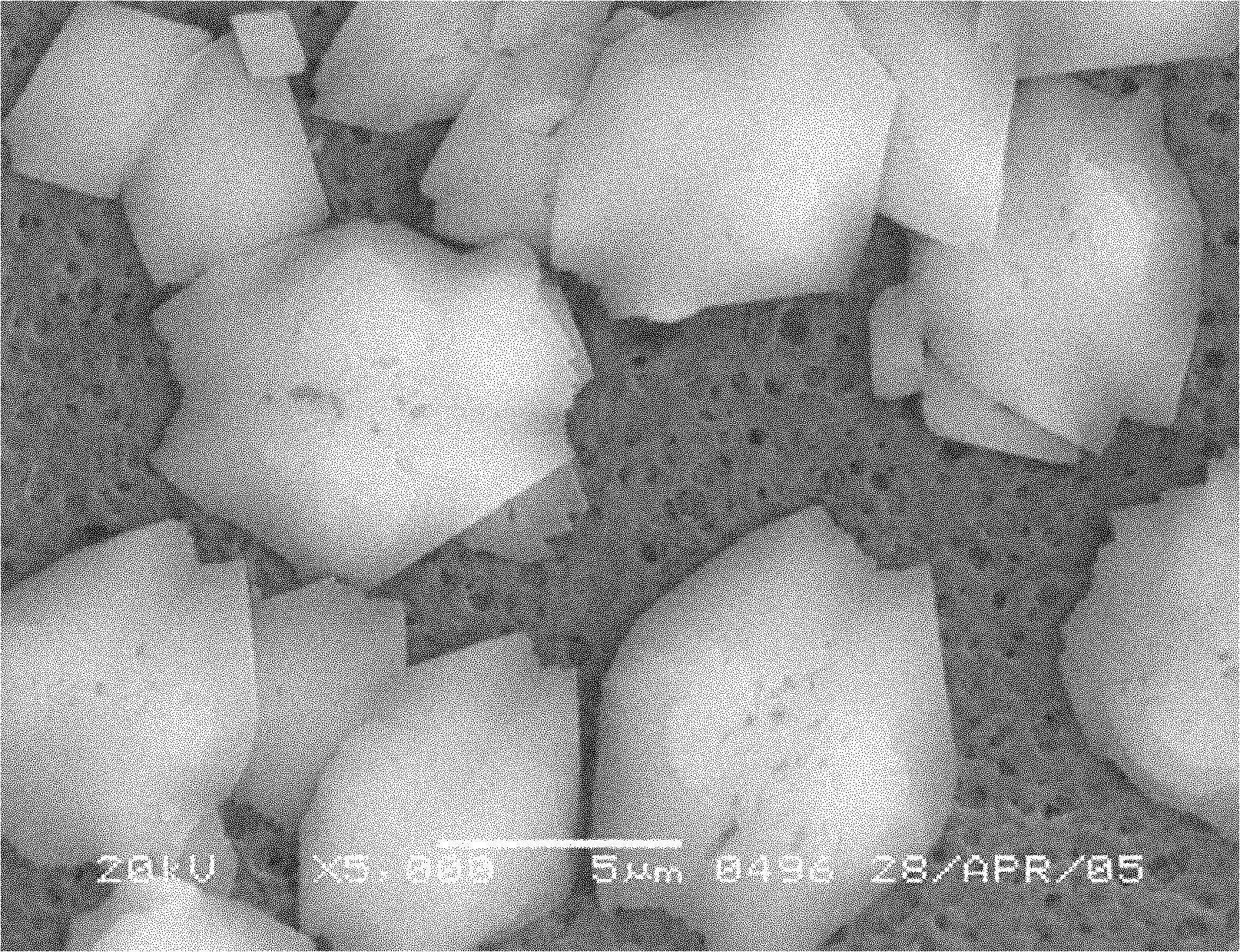

[0016] 1) Take 100ml of 0.05mol / L zinc nitrate solution and store it in the reactor, add 0.1g / L citric acid, start stirring, and adjust its pH=2.5; 2) Take 100ml of 0.06mol / L ammonium oxalate solution , adjust the pH=6.0; 3) Put the above two solutions into the reactor at a speed of 2mL / min and drop them into the reactor. After washing 4-5 times, send it to a drying oven for drying to obtain a flake zinc oxalate powder product with pearlescent luster; 4) heat the zinc oxalate powder in a tubular calciner to 480°C for 1 After one hour, take it out and air-cool it directly to obtain flaky zinc oxide powder with pearlescent luster. The morphology and other characteristics of the powder were characterized by a scanning electron microscope (JEOL JSM-5600LV type), see attached figure 1 with 2 .

Embodiment approach 2

[0018] 1) Take 100ml of 0.10mol / L zinc nitrate solution and store it in the reactor, add 0.3g / L sodium citrate, start stirring, and adjust its pH=2.5; 2) Take 100ml of 0.12mol / L ammonium oxalate solution, adjust the pH=6.0; 3) The above two solutions are dripped into the reactor at a speed of 2mL / min. Repeated washing 4-5 times, sent to drying oven to dry, you can get flake zinc oxalate powder product with pearl luster; 4) heat the zinc oxalate powder in a tubular calciner to 420°C After 1 hour, take it out and air-cool directly to obtain flaky zinc oxide powder with pearlescent luster. The morphology and other characteristics of the powder are similar to those of Embodiment 1.

Embodiment approach 3

[0020]1) Take 100ml of 0.20mol / L zinc nitrate solution and store it in the reactor, add 0.35g / L ammonium citrate, start stirring, and adjust its pH=3.0; 2) Take 100ml of 0.24mol / L ammonium oxalate solution, adjust the pH=7.0; 3) The above two solutions are dripped into the reactor at a speed of 5mL / min. Repeated washing 4-5 times, sent to the drying oven to dry, you can get flaky zinc oxalate powder product with pearl luster; 4) Heat the zinc oxalate powder in a tubular calciner to 450°C for heat preservation After 1 hour, take it out and air-cool directly to obtain flaky zinc oxide powder with pearlescent luster. The morphology and other characteristics of the powder are similar to those of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com