Multi-layer drum-type destructive distillation process and retort furnace for oil shale

A technology of oil shale and retort furnace, which is applied in special forms of retort, petroleum industry, direct heating retort, etc. It can solve the problems of large structure, difficult adjustment of retort time, uneven retort, etc., and achieve high heat transfer efficiency and high efficiency , sufficient dry distillation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

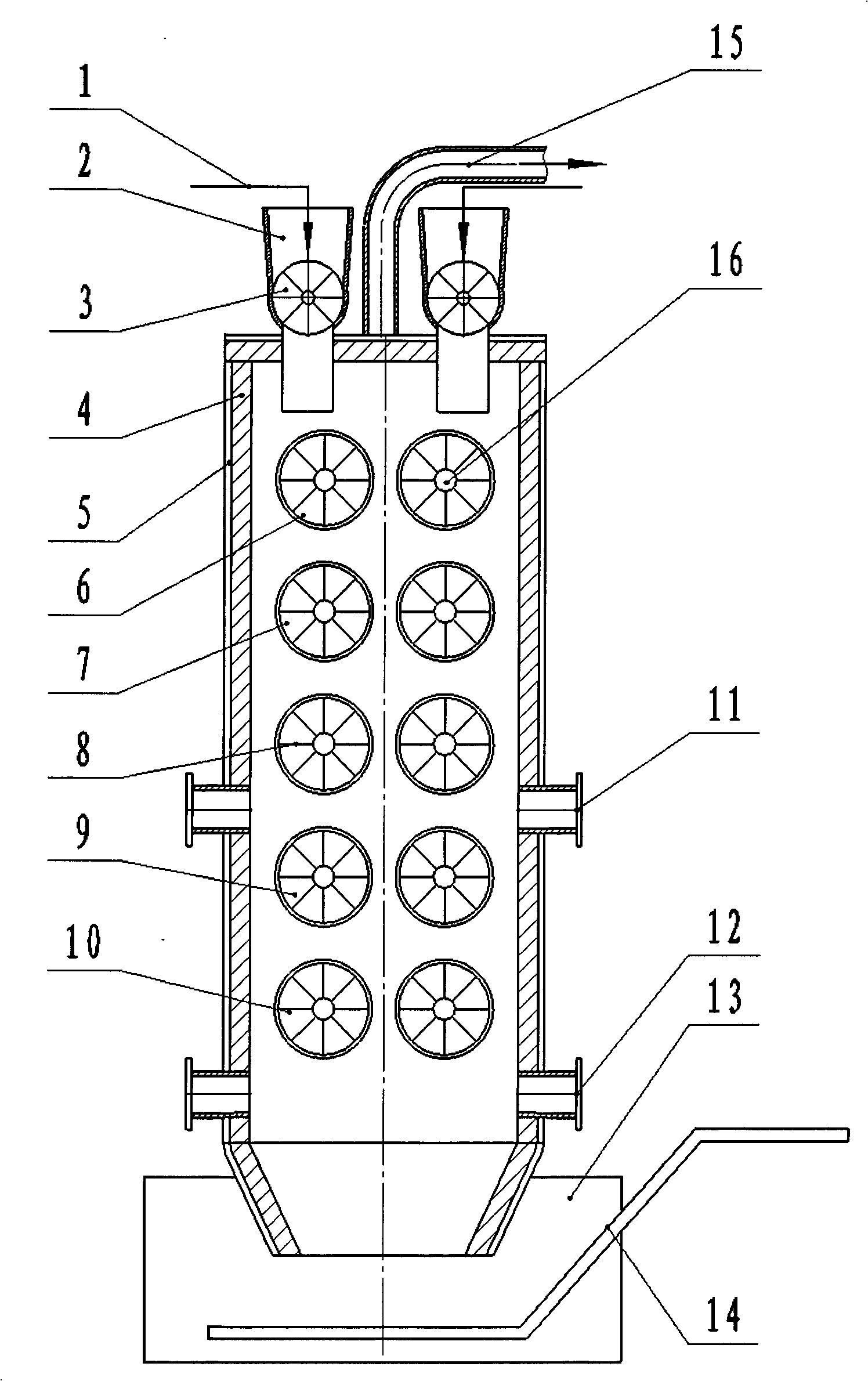

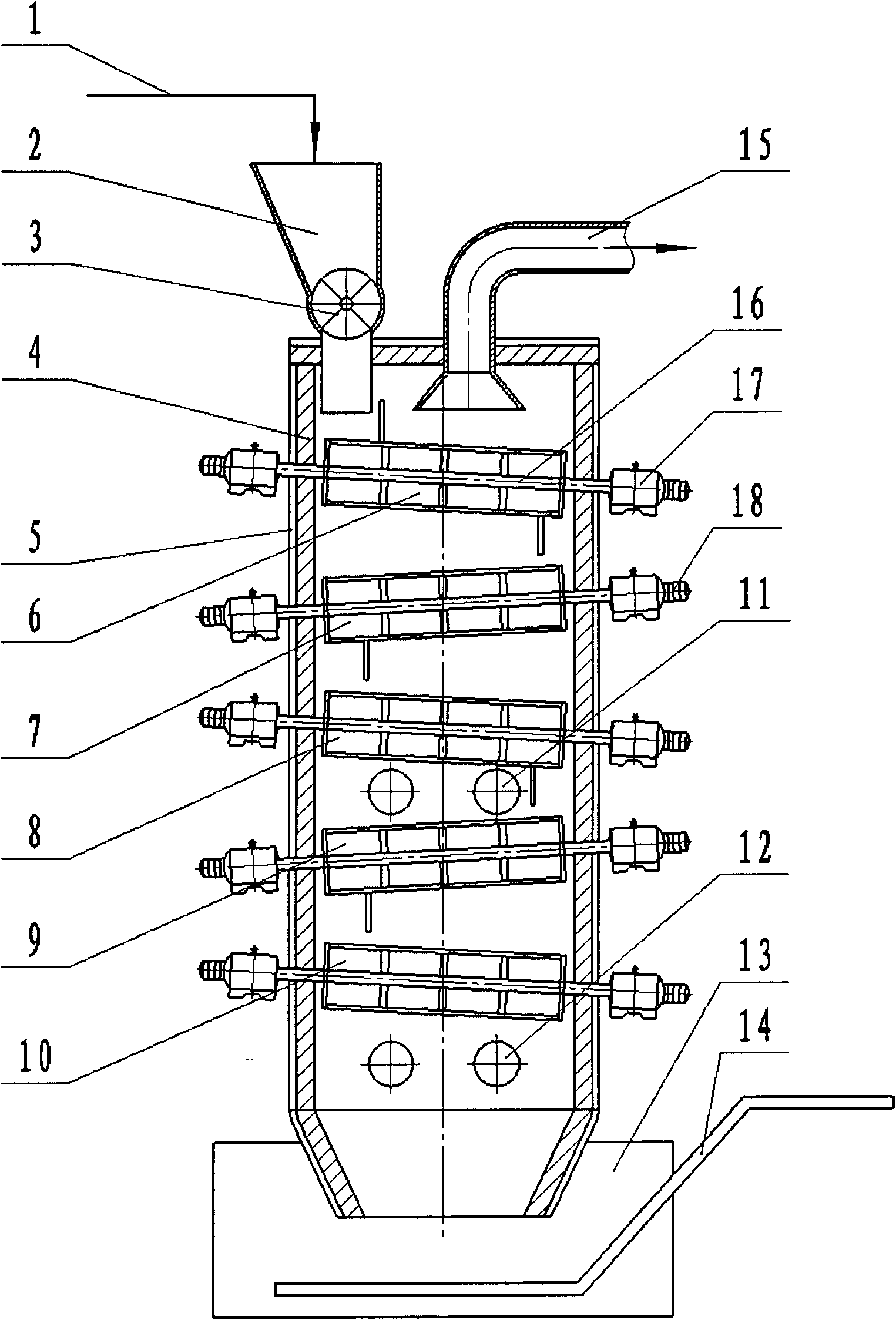

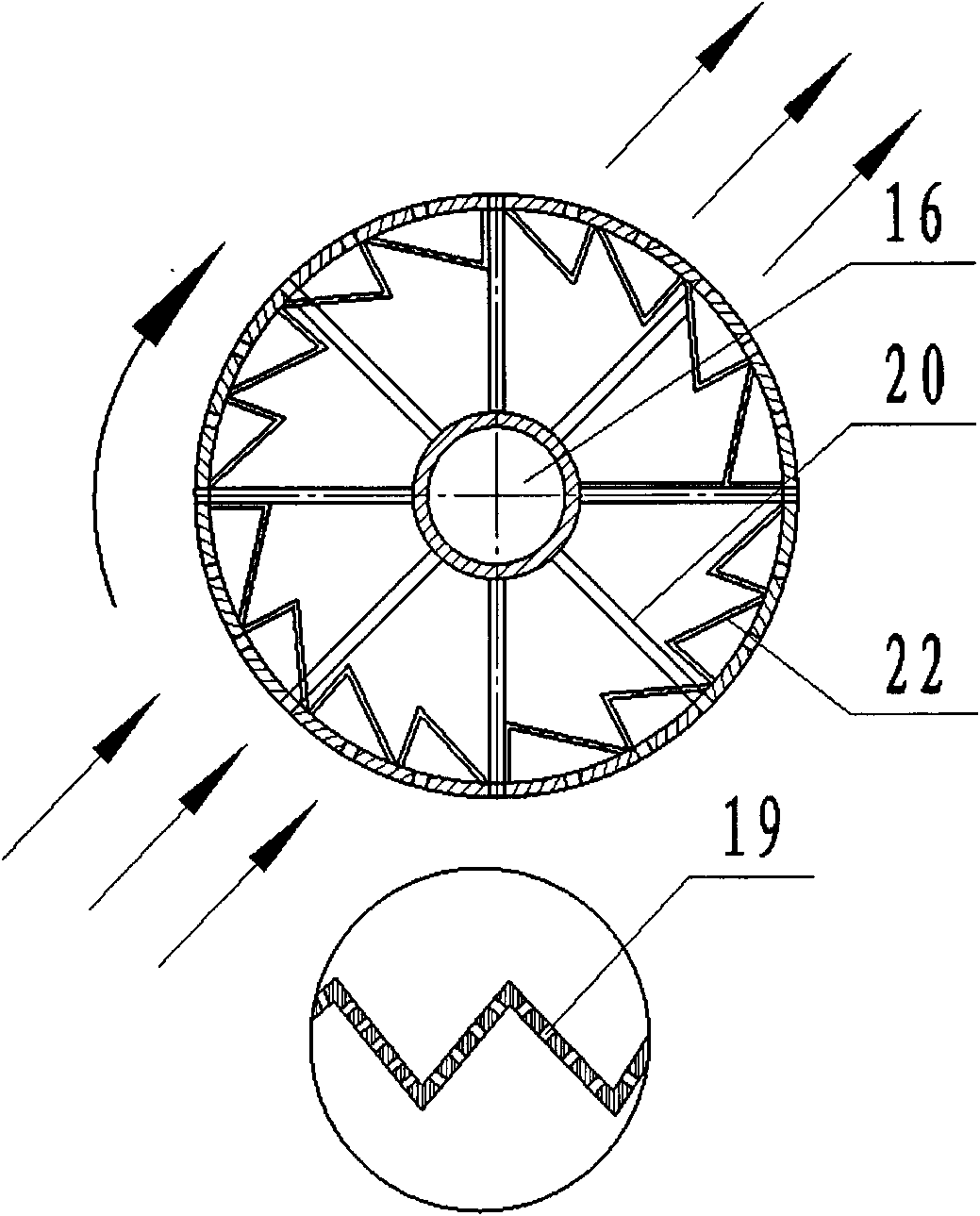

[0018] attached figure 1 It is the working principle diagram of the 5-layer drum oil shale retort furnace, attached figure 2 It is a structural schematic diagram of a 5-layer drum oil shale retort furnace. It can be seen from the figure that the oil shale is broken into small pieces smaller than 25 mm, and the oil shale is sent to the top hopper (2) of the carbonization furnace through the ore conveying device (1), and the oil shale is sent to the top hopper (2) of the carbonization furnace by the feeder (3). Put into the retort furnace, fall into the first layer of drums (6), the drum axis (16) is driven by the motor (18) through the gearbox (17), rotates continuously, and is installed on the drum spokes (20) The drum also rotates accordingly, and the oil shale in the drum rolls continuously in the drum. A drum lifting board (22) is installed on the drum wall, and air holes (19) are opened on the drum lifting board (22). The air flow enters the drum from the pores (19), fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com