Low-temperature high pressure balancing plug valve

A low temperature and high pressure, plug valve technology, applied in the direction of the plug including the cut-off device, valve details, valve device, etc., can solve the problems of high use cost, small sealing surface, easy to contain sediment, etc., to save time and effort, simplify the operation effect of structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

[0024] In order to illustrate the low-temperature, high-pressure, and pressure-balanced plug valve of the present invention in conjunction with the accompanying drawings, it is specified that the inner cavity at the end of the bottom cover (8) is the lower cavity 36, and the end of the valve stem 15 is the upper cavity 38.

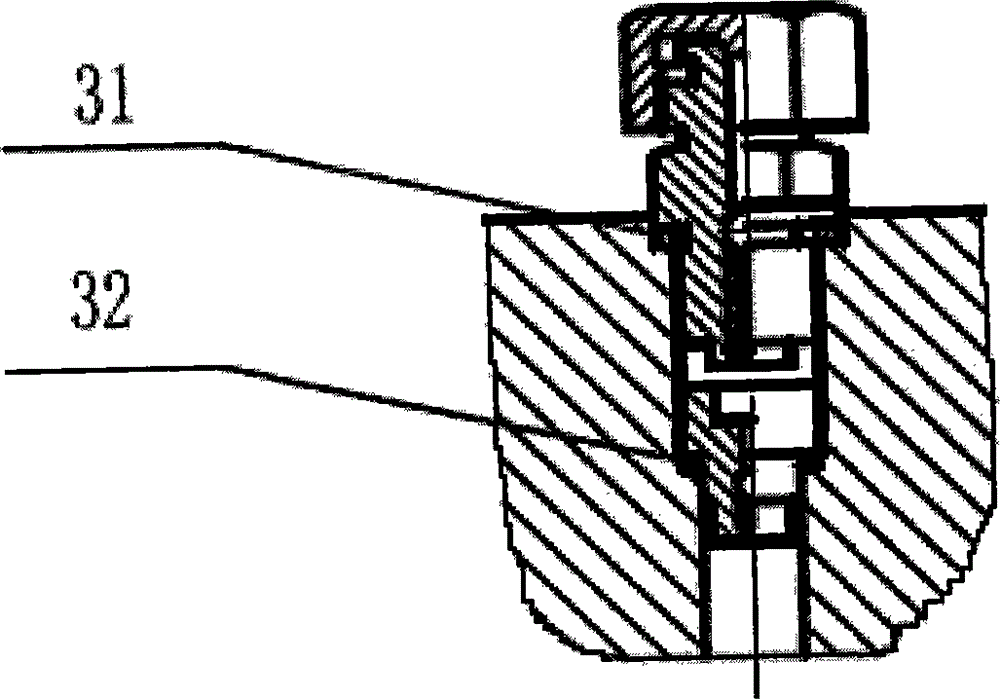

[0025] The low-temperature, high-pressure, pressure-balanced plug valve of the present invention includes a valve body 29, a connecting plate 24, and a bottom cover (8), which are connected by hexagonal socket head bolts 21, full-thread studs 3, 4, and nuts 5 to form the overall plug valve. The upper end is equipped with a pressure self-sealing valve stem 15, and the upper end of the valve stem is connected with the manual device 25 through a flat key 26 to control the opening and closing of the cock valve. Tapered hole, the floating axial positioni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com