Non-aqueous electrolyte secondary battery

A non-aqueous electrolyte and secondary battery technology, applied in the direction of non-aqueous electrolyte batteries, non-aqueous electrolyte battery electrodes, battery electrodes, etc., can solve the problems of being unable to suppress storage deterioration and cycle deterioration, and difficult to obtain the effect of chelating agent addition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

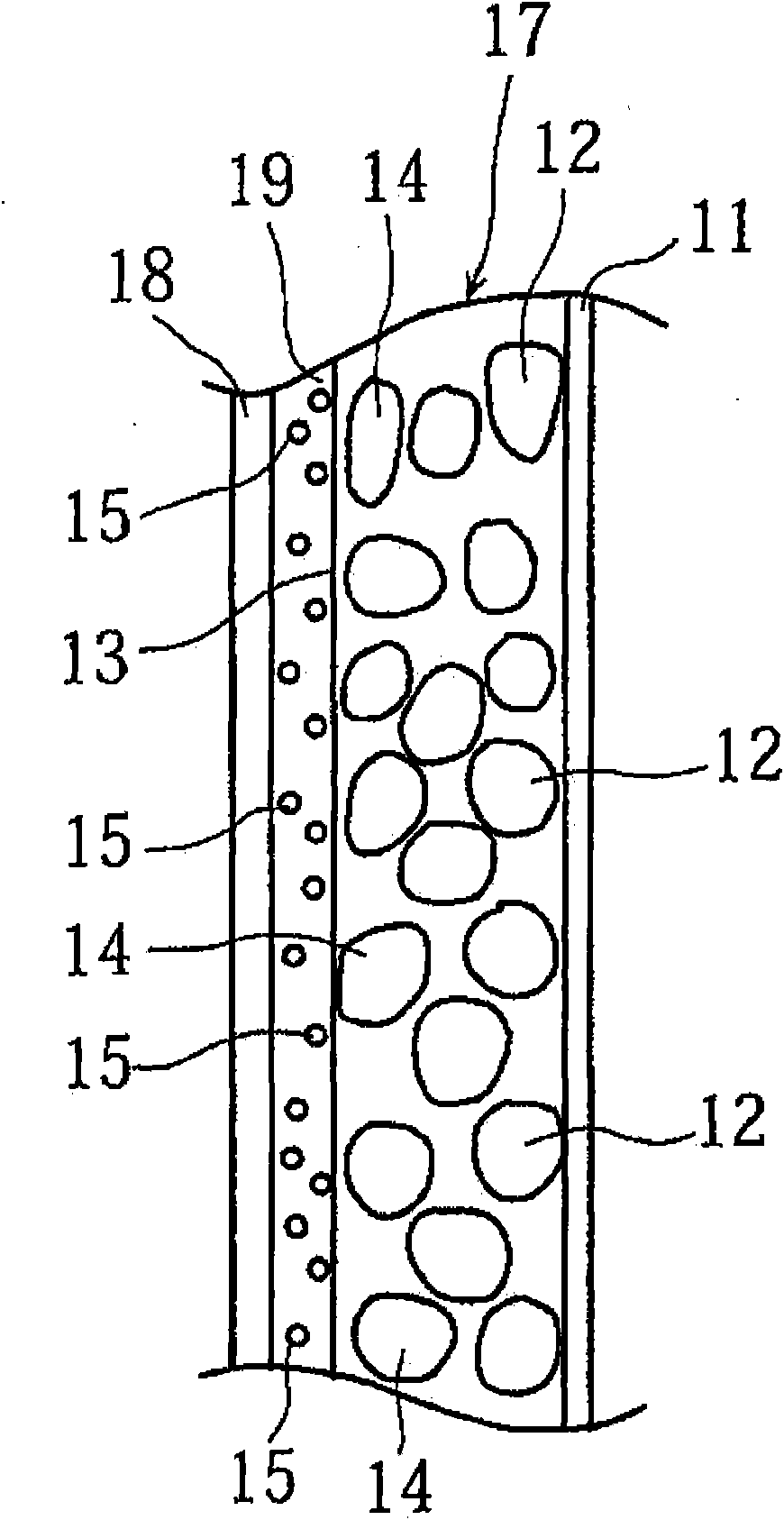

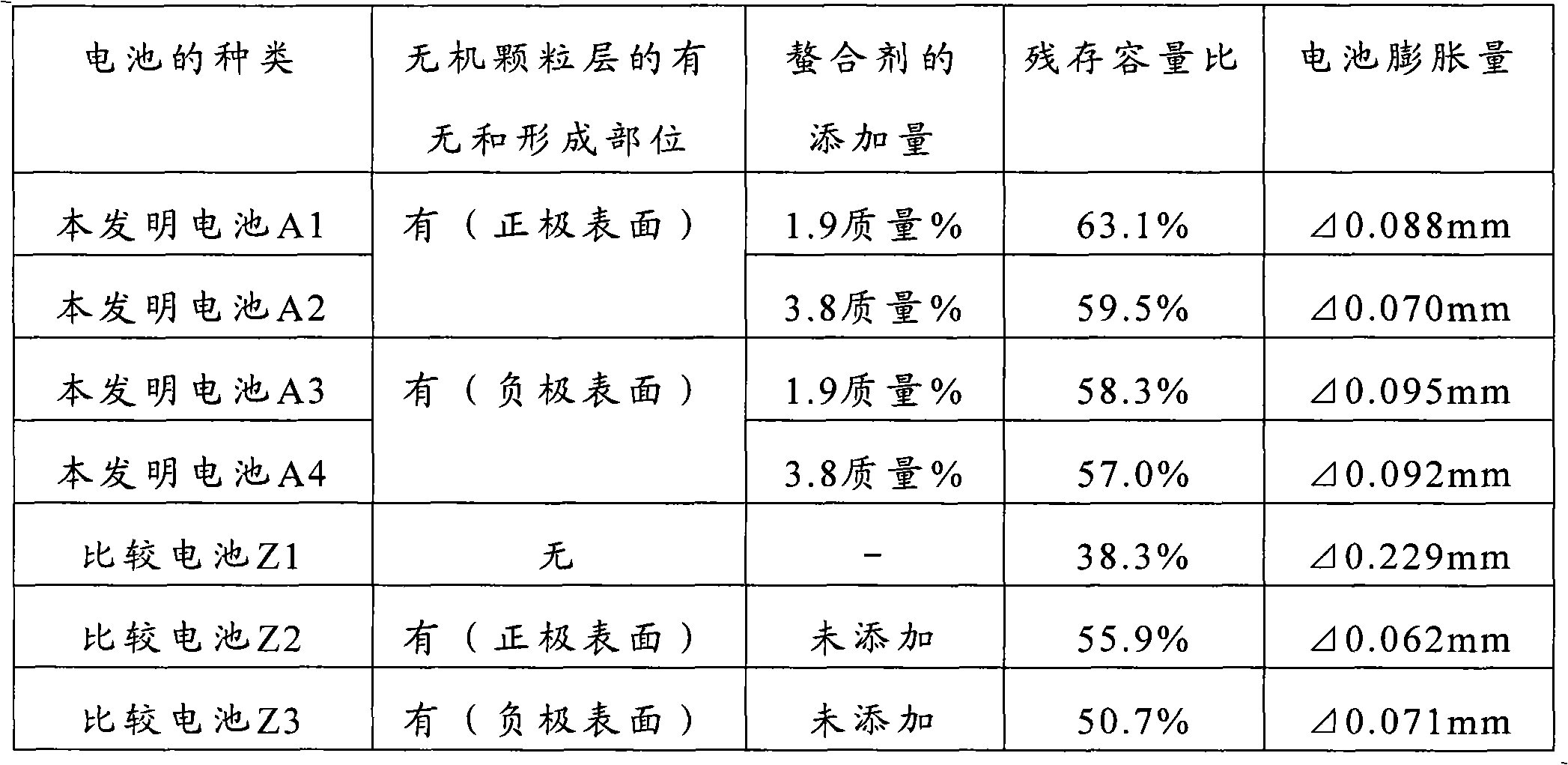

[0106] A battery was produced in the same manner as for carrying out the above-mentioned invention.

[0107] The battery produced in this way is hereinafter referred to as battery A1 of the present invention.

Embodiment 2

[0109] In preparation of the inorganic particle layer on the surface of the positive electrode, a battery was produced in the same manner as in Example 1 above, except that the ratio of the chelating agent to the inorganic particles was 3.8% by mass.

[0110] The battery produced in this way is hereinafter referred to as battery A2 of the present invention.

Embodiment 3

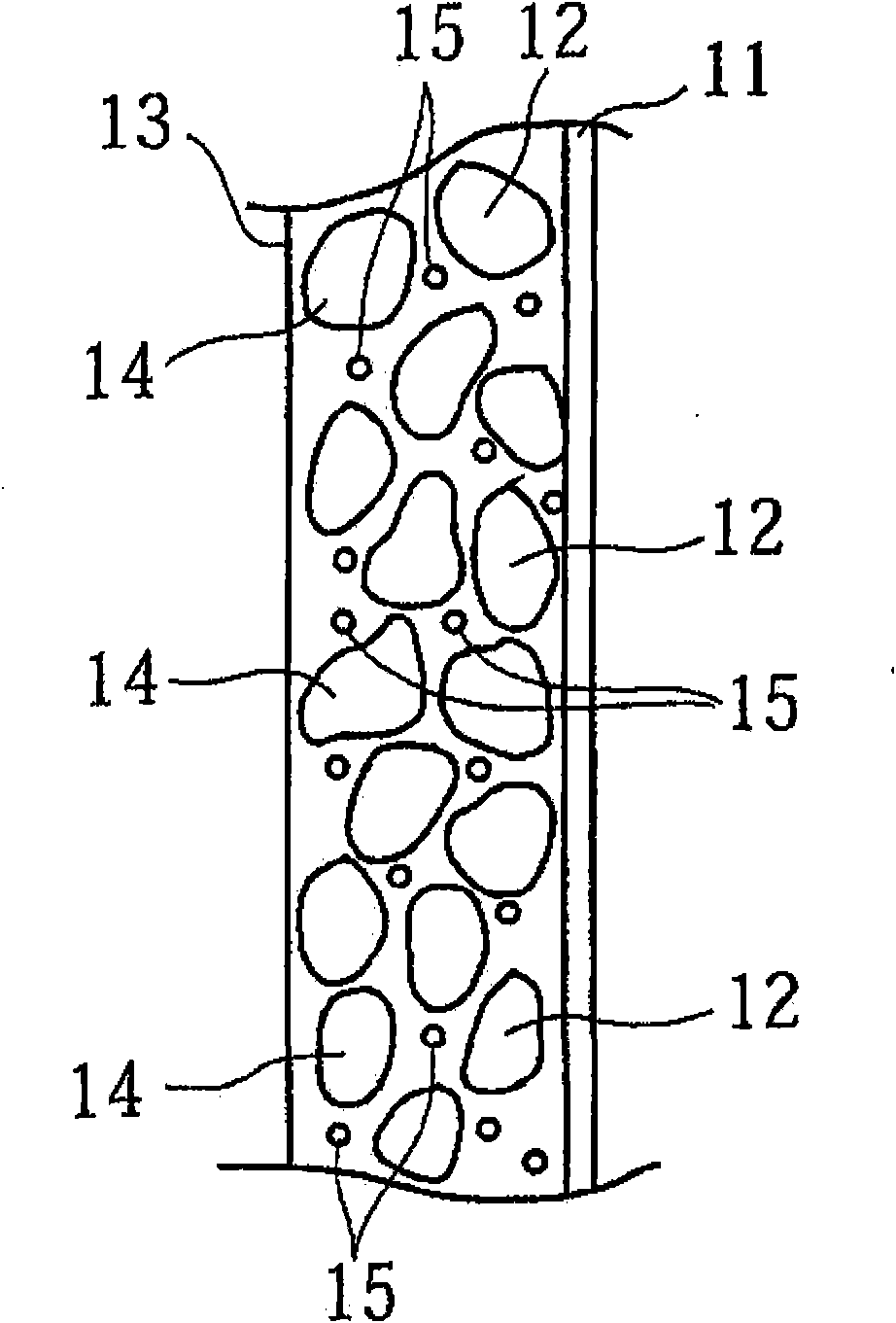

[0112] A battery was produced in the same manner as in Example 1 above, except that no inorganic particle layer was formed on the surface of the positive electrode and an inorganic particle layer was formed on the surface of the negative electrode by the following method.

[0113] First, NMP is used as the solvent, and titanium oxide (TiO 2 , average particle size: 0.25 μm, no surface treatment layer, Ishihara Sangyo Co., Ltd. product name "CR-EL"), PVDF (polyvinylidene fluoride) was used for the NMP-based binder, and ethylenediaminetetraacetic acid was used as the chelating agent. NMP-based slurry for forming an inorganic particle layer. At this time, the solid content concentration of the inorganic particles was 30% by mass, and the ratios of the binder and the chelating agent to the inorganic particles were 3.5% by mass and 1.9% by mass, respectively. Next, in the same manner as in Example 1, the NMP-based slurry was coated on both sides of the negative electrode by gravur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com