UV extruding and transfer printing forming process

A molding process and printing layer technology, applied in the field of UV extrusion transfer molding process, can solve the problem of low curvature and achieve the effect of high curvature extrusion transfer and good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

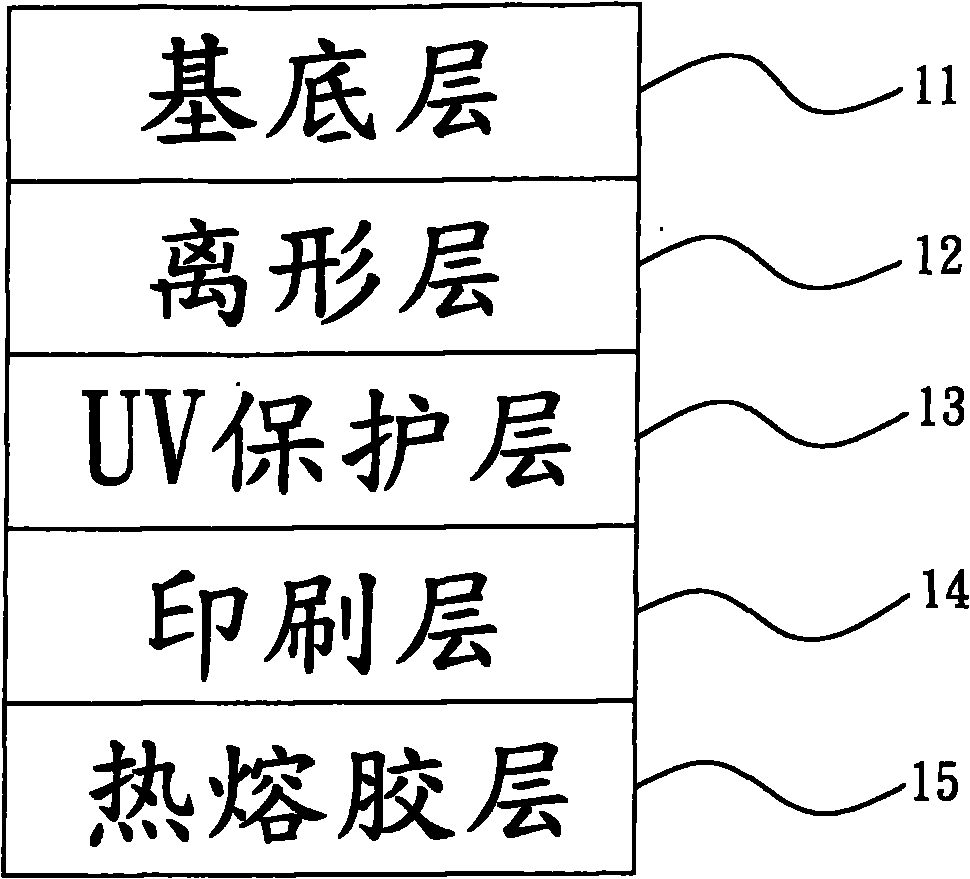

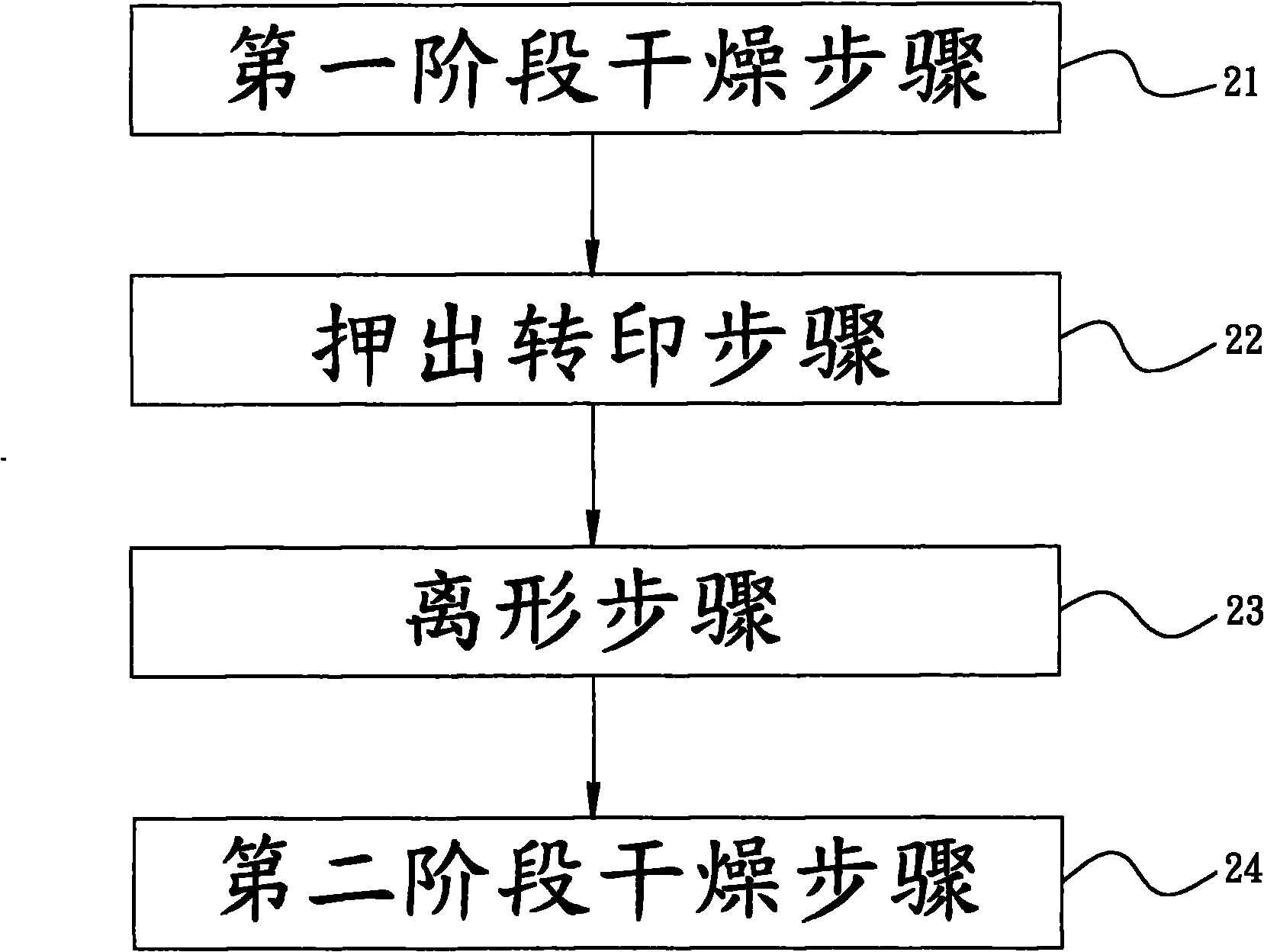

[0037] The present invention relates to a UV extrusion transfer molding process, which is an extrusion transfer printing process for secondary drying and molding of plastic extrusion, foam extrusion or filling molded products, and UV protective layers are provided respectively through secondary drying methods It is formed on the transfer film, and the transfer film with UV protective layer is used for extrusion transfer process, so that the UV protective layer can still maintain its flexural tension and good adhesion during the extrusion transfer process, enabling high curvature Press transfers without chipping, see figure 1 As shown, it is the transfer film required for the application of the "UV extrusion transfer molding process" of the present invention;

[0038] Its transfer printing film has base layer 11, release layer 12, UV protection layer 13, printing layer 14 and hot-melt adhesive layer 15 in sequence, and this base layer 11 is to be used as for UV protection laye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com