Nickel zinc ferrite material with initial permeability of 10+/-20 percent and preparation method thereof

A technology of nickel-zinc ferrite and initial magnetic permeability, applied in the field of nickel-zinc ferrite material production, can solve the problems of high saturation magnetic flux density, too high magnetic permeability, unable to work normally, etc., and achieve high saturation Good effects on magnetic flux density, reduced heat generation, process repeatability and product consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

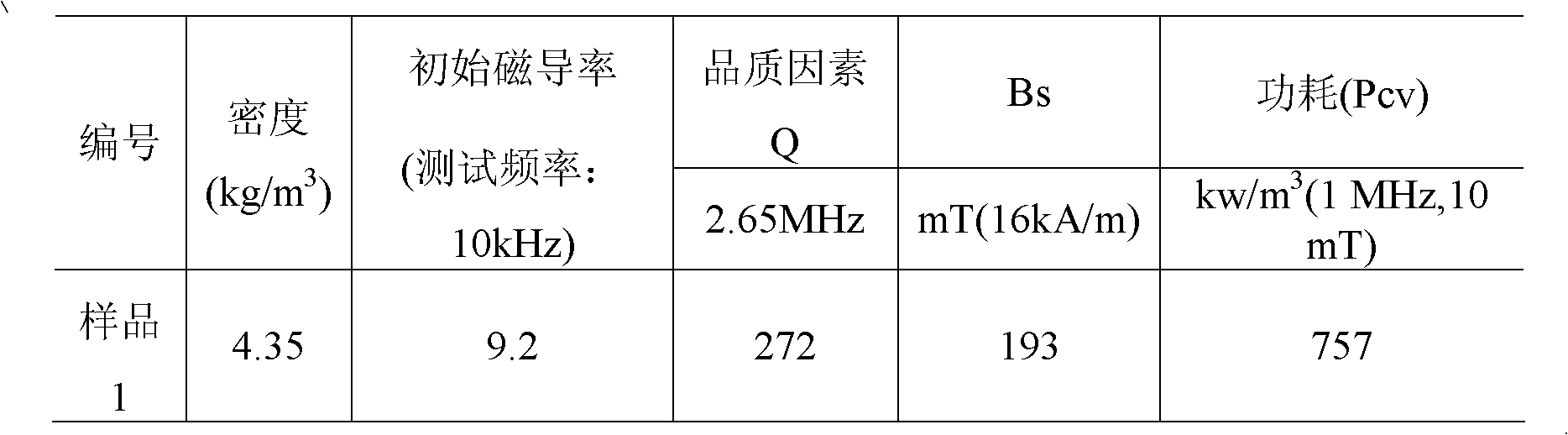

Embodiment 1

[0048] 1) Selection of raw materials: The initial magnetic permeability provided by the present invention is 10±20%, which has high frequency, low electromagnetic loss and high saturation magnetic flux density under relatively large operating current, and can be used to produce high frequency electrodeless lamp power generation The raw material of the nickel-zinc ferrite material of the choke coil in the device is industrially pure Fe 2 o 3 , ZnO, NiO and CoO.

[0049] 2) Composition design and weighing: according to Fe 2 o 3 49 mol%, ZnO 0.2 mol%, NiO 49 mol%, and CoO 1.8 mol%.

[0050] 3) Mixing of raw materials: Put the weighed raw materials into a sand mill, add deionized water, the weight of deionized water is 1.2 times of the total weight of raw materials, and the ball milling time is 2 hours.

[0051] 4) Pre-burning: Dry the raw materials that have been ball-milled once, and put them into an electric furnace for pre-burning. The pre-burning temperature is 1150°C, an...

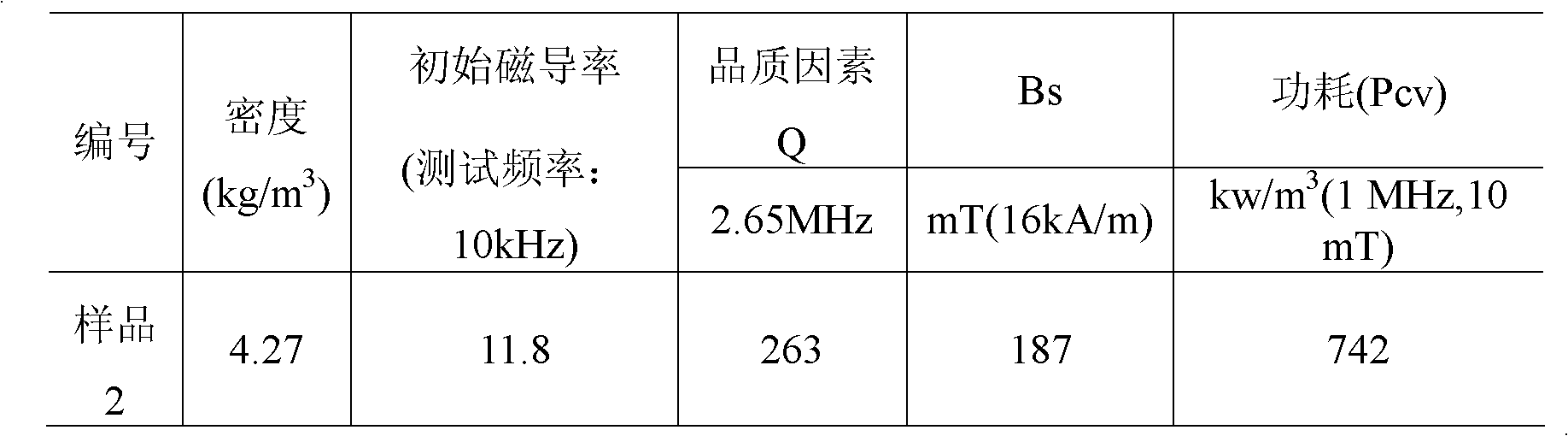

Embodiment 2

[0061] 1) Selection of raw materials: The initial magnetic permeability provided by the present invention is 10±20%, which has high frequency, low electromagnetic loss and high saturation magnetic flux density under relatively large operating current, and can be used to produce high frequency electrodeless lamp power generation The raw material of the nickel-zinc ferrite material of the choke coil in the device is industrially pure Fe 2 o 3 , ZnO, NiO and CoO.

[0062] 2) Composition design and weighing: according to Fe 2 o 3 is 49 mol%, ZnO is 4.5 mol%, NiO is 44 mol%, and CoO is 2.5 mol%.

[0063] 3) Mixing of raw materials: Put the weighed raw materials into a sand mill, add deionized water, the weight of deionized water is 1.2 times of the total weight of raw materials, and the ball milling time is 1 hour.

[0064] 4) Pre-burning: Dry the raw materials that have been ball-milled once, and put them into an electric furnace for pre-burning. The pre-burning temperature is...

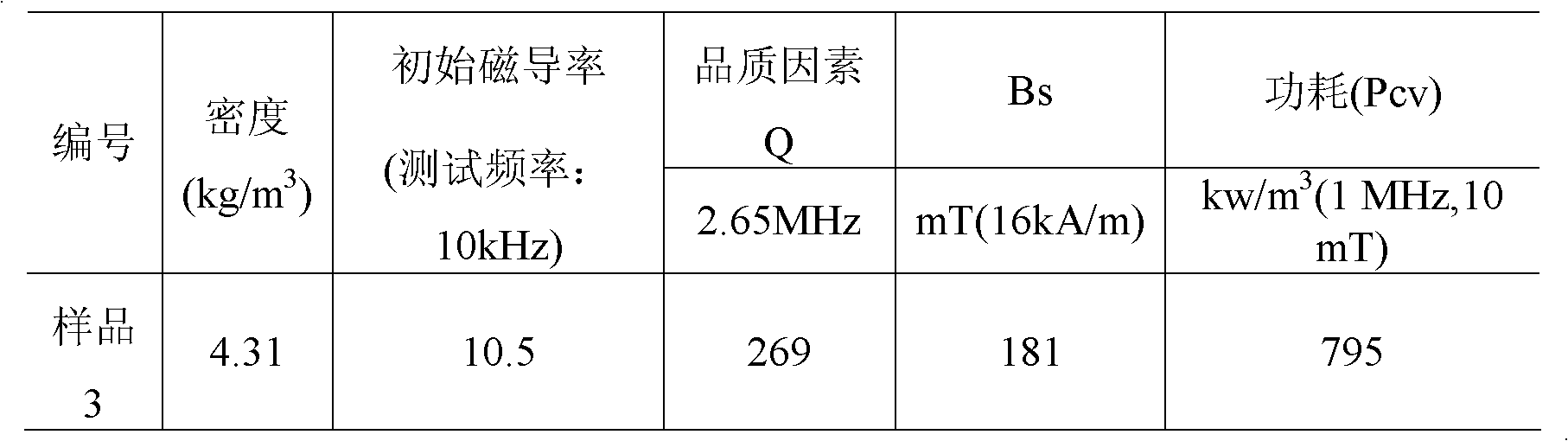

Embodiment 3

[0074] 1) Selection of raw materials: The initial magnetic permeability provided by the present invention is 10±20%, which has high frequency, low electromagnetic loss and high saturation magnetic flux density under relatively large operating current, and can be used to produce high frequency electrodeless lamp power generation The raw material of the nickel-zinc ferrite material of the choke coil in the device is industrially pure Fe 2 o 3 , NiO and CoO.

[0075] 2) Composition design and weighing: according to Fe 2 o 3 46.5 mol%, ZnO 4.2 mol%, NiO 49 mol%, and CoO 0.3 mol%.

[0076] 3) Mixing of raw materials: Put the weighed raw materials into a sand mill, add deionized water, the weight of deionized water is 1.2 times of the total weight of raw materials, and the ball milling time is 1.5 hours.

[0077]4) Pre-burning: Dry the raw materials that have been ball-milled once, and put them into an electric furnace for pre-burning. The pre-burning temperature is 1050°C, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle size | aaaaa | aaaaa |

| Power consumption | aaaaa | aaaaa |

| Saturation flux density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com