Method for in-situ polymerizing and preparing polypyrrole-coated polylactic acid electrospun composite membrane

A polypyrrole-coated lactic acid and electrospinning technology, which is used in textiles and papermaking, fiber treatment, coating, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

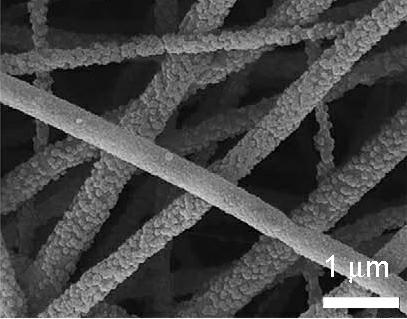

Embodiment 1

[0016] 0.008 mole of pyrrole was dissolved in 1 liter of deionized water to obtain a 0.008 mole / liter pyrrole solution; 0.008 mole of sodium benzenesulfonate was dissolved in 1 liter of deionized water to obtain a 0.008 mole / liter sodium benzenesulfonate solution; 0.02 mole of ferric chloride is dissolved in 1 liter of deionized water to obtain 0.02 mol / liter of ferric chloride solution; pyrrole solution and sodium benzenesulfonate solution are mixed according to a volume ratio of 5: 5, and 0.016 mole / liter of pyrrole and sodium benzenesulfonate mixed solution; put a 20 × 20 square mm homemade polylactic acid electrospun membrane into 2 ml of pyrrole and sodium benzenesulfonate mixed solution, at 1 ~ 4 o After soaking for 1 hour at C, add 2 milliliters of ferric chloride solution; o C for 12 hours; take out the electrospun membrane, and dry it at room temperature for 24 hours to obtain a polypyrrole-coated polylactic acid electrospun composite membrane. The average fiber diam...

Embodiment 2

[0018] 0.008 mole of pyrrole was dissolved in 1 liter of deionized water to obtain a 0.008 mole / liter pyrrole solution; 0.008 mole of sodium benzenesulfonate was dissolved in 1 liter of deionized water to obtain a 0.008 mole / liter sodium benzenesulfonate solution; 0.02 mole of ferric chloride is dissolved in 1 liter of deionized water to obtain 0.02 mol / liter of ferric chloride solution; pyrrole solution and sodium benzenesulfonate solution are mixed according to the volume ratio of 6:4, and 0.016 mole / liter of pyrrole and sodium benzenesulfonate mixed solution; put a 20 × 20 square mm homemade polylactic acid electrospun membrane into 2 ml of pyrrole and sodium benzenesulfonate mixed solution, at 1 ~ 4 o After soaking for 1 hour at C, add 2 milliliters of ferric chloride solution; o C for 24 hours; take out the electrospun membrane, and dry it at room temperature for 24 hours to obtain a polypyrrole-coated polylactic acid electrospun composite membrane. The average fiber dia...

Embodiment 3

[0020] 0.008 mole of pyrrole was dissolved in 1 liter of deionized water to obtain a 0.008 mole / liter pyrrole solution; 0.008 mole of sodium benzenesulfonate was dissolved in 1 liter of deionized water to obtain a 0.008 mole / liter sodium benzenesulfonate solution; 0.02 mole of ferric chloride is dissolved in 1 liter of deionized water to obtain 0.02 mol / liter of ferric chloride solution; pyrrole solution and sodium benzenesulfonate solution are mixed according to the volume ratio of 4: 6, and 0.016 mole / liter of pyrrole and sodium benzenesulfonate mixed solution; put a 20 × 20 square mm homemade polylactic acid electrospun membrane into 2 ml of pyrrole and sodium benzenesulfonate mixed solution, at 1 ~ 4 o After soaking for 1 hour at C, add 2 milliliters of ferric chloride solution; o C for 36 hours; take out the electrospun membrane, and dry it at room temperature for 24 hours to obtain a polypyrrole-coated polylactic acid electrospun composite membrane. The average fiber di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com