Method for low loss welding and end face treatment of photonic crystal optical fiber

A technology of photonic crystal fiber and end face treatment, which is applied in the coupling direction of optical waveguide, can solve the problems of mode field mismatch loss, limited application occasions, high cost, etc., to reduce optical coupling loss, maintain excellent characteristics, and increase connection strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

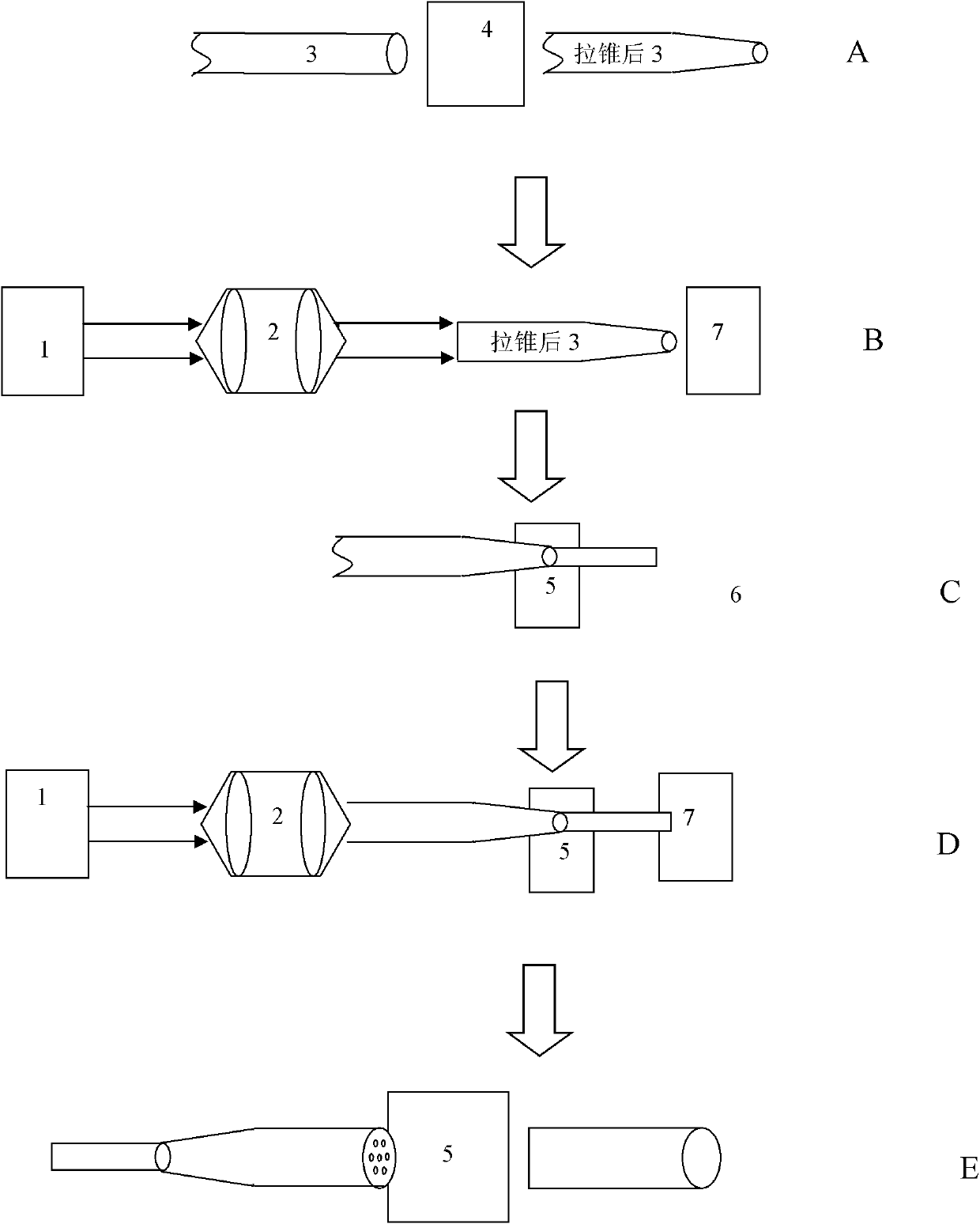

[0018] The method for low-loss fusion splicing and end face treatment of the photonic crystal fiber of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments. The process flow is shown in figure 1 .

[0019] In the first step, the fiber materials to be fused are: the mode field diameter of the photonic crystal fiber is 29 μm@976nm, and the mode field diameter of the other ordinary single-mode fiber is 9.5 μm.

[0020] Using the formula (1) to calculate the loss value of conventional welding is 4.56dB.

[0021] The above two optical fibers to be fused are cut flat with an optical fiber cutter, and according to the difference in the mode field parameters of the optical fibers to be fused, use an optical fiber tapering machine 4 to perform tapering treatment on the photonic crystal fiber 3 to change the mode field diameter. about. And according to (1) in the flowchart, the 976nm semiconductor laser 1 laser light wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com