Solid oxide direct carbon fuel cell stack of tablet bubbling bed

A technology of solid oxide and fuel cell stacks, applied in the direction of solid electrolyte fuel cells, fuel cell groups, fuel cell components, etc., to solve the problem of continuous feeding, improve overall performance, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

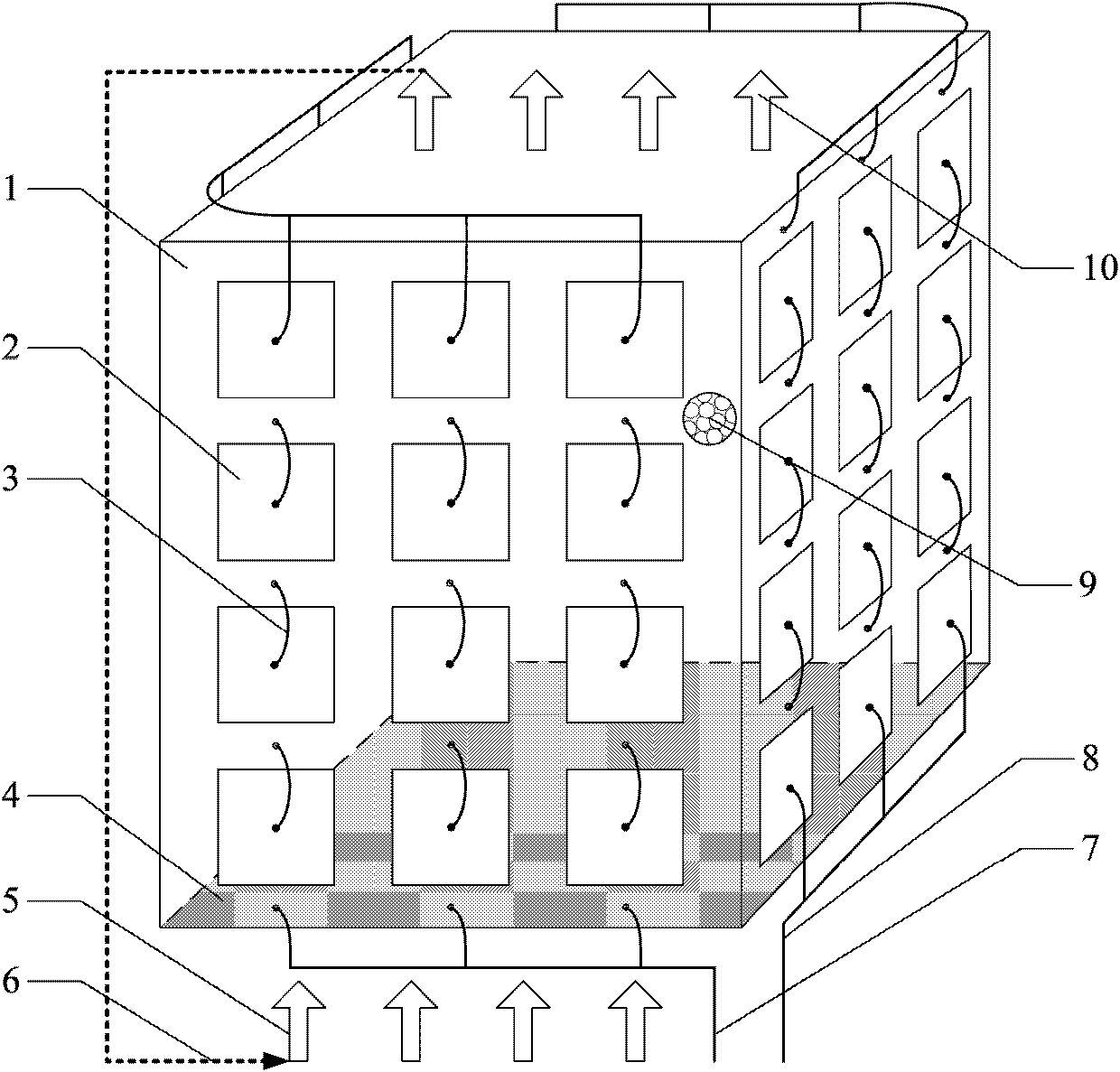

[0032] Example 1, see Figure 5 , this embodiment is composed of 48 anode-supported flat-plate fuel cell cells 2, and the size of the cell cell is about 10 cm × 10 cm; graphite with a particle size of 5 mm to 50 μm is used as the solid carbon fuel; the anode carrier gas component is pure CO 2 After the reaction, 70% of the anode carrier gas is exported for recycling; the working temperature of the battery stack is 800°C.

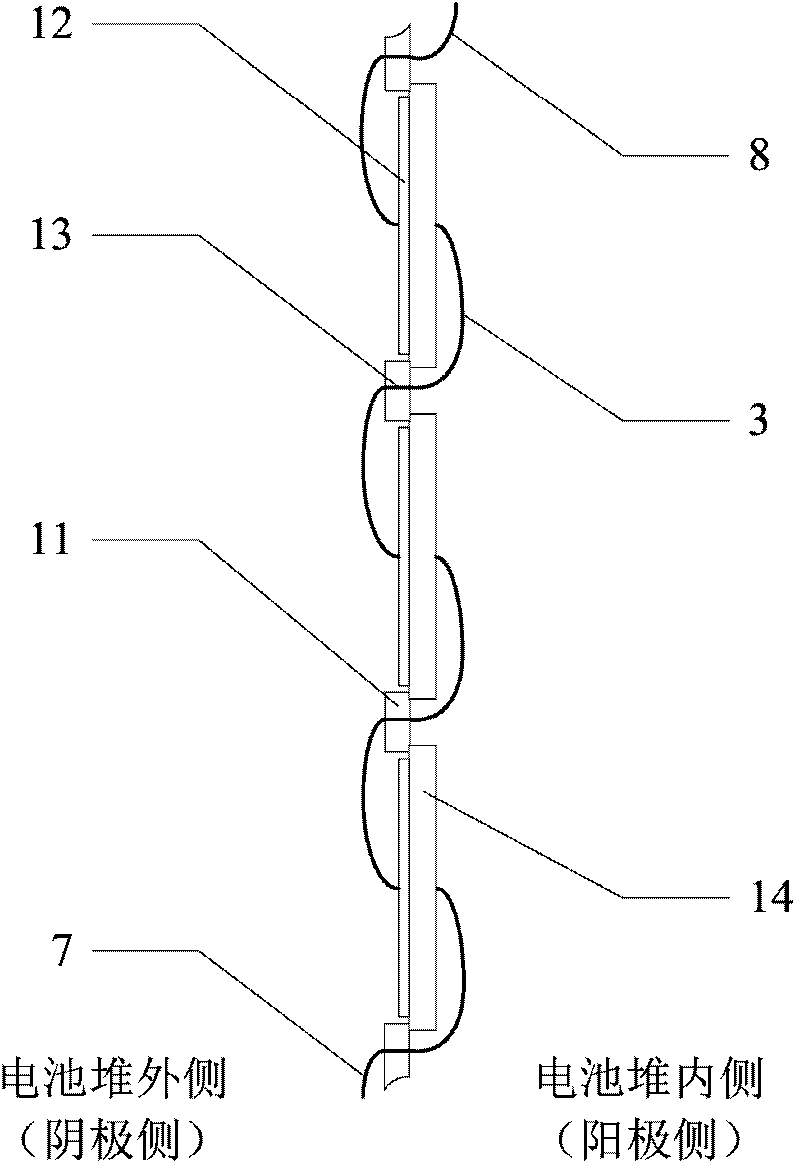

[0033] There are 3×4 (horizontal×vertical) rectangular holes of about 10cm×10cm on the walls around the bubbling bed, and the anode-supported flat-plate fuel cell cells 2 are respectively installed at the openings on the wall of the bubbling bed. The flat fuel cell unit 2 is composed of an anode 14 , an electrolyte 17 , and a cathode 12 in a three-layer structure. Among them, the anode 14 is the thickest and plays a supporting role to ensure the mechanical strength of the battery cell; the cathode 12 and the electrolyte 17 are relatively thin; the anode 14 ...

Embodiment 2

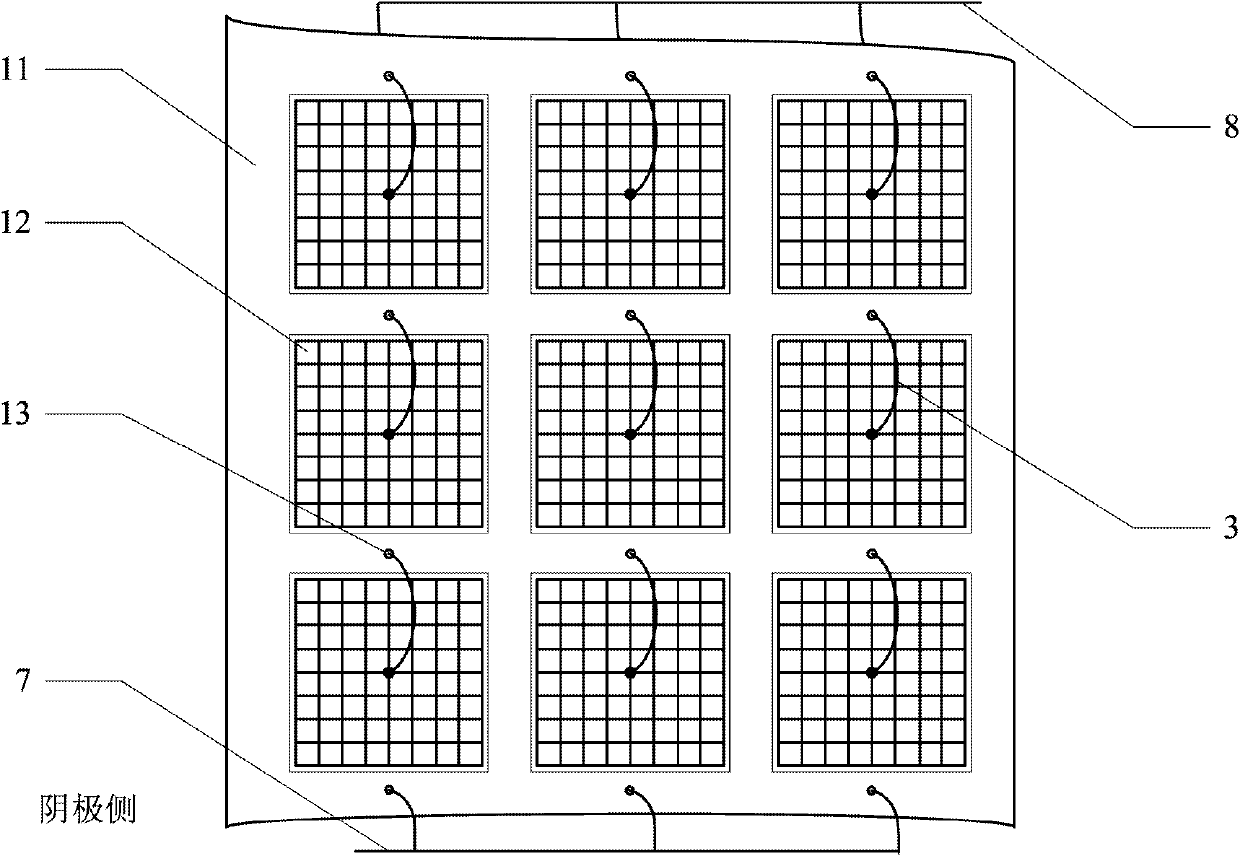

[0035] Example 2, see Figure 6 , this embodiment is composed of 64 electrolyte-supported flat-plate fuel cell cells 2, and the size of the cell cell is about 8cm×8cm; carbon black with a particle size of 5 mm to 100 μm is used as the solid carbon fuel; the anode carrier gas component is 70% CO 2 +30%H 2 O, 50% of the anode carrier gas exported after the reaction is used for recycling; the working temperature of the battery stack is 900°C.

[0036] There are 4×4 (horizontal×vertical) rectangular holes of about 8cm×8cm on the walls around the bubbling bed, and the electrolyte-supported flat-plate fuel cell cells 2 are respectively installed at the openings on the wall of the bubbling bed. Among them, the electrolyte 17 is the thickest and plays a supporting role, and the cathode 12 and the anode 14 are relatively thin; the electrolyte 17 has a larger area, while the area of the cathode 12 and the anode 14 is slightly smaller than the electrolyte 17, and the electrolyte 17 i...

Embodiment 3

[0037] Example 3, see Figure 7 , this embodiment is composed of 100 cathode-supported flat-plate fuel cell cells 2, and the size of the cell cells is about 9cm×9cm; coal with a particle size of 5mm to 200μm is used as solid carbon fuel; the anode carrier gas component is 50% CO 2 +30%H 2 O+20%N 2 After the reaction, the outlet anode carrier gas is directly evacuated; the working temperature of the battery stack is 1000 °C.

[0038] There are 5×5 (horizontal×vertical) rectangular holes of about 9cm×9cm on the walls around the bubbling bed, and the cathode-supported flat-plate fuel cell cells 2 are respectively installed at the openings on the wall of the bubbling bed. Among them, the cathode 12 is the thickest and plays a supporting role, and the anode 14 and the electrolyte 17 are relatively thin; the cathode 12 and the electrolyte 17 have the same area, while the area of the anode 14 is slightly smaller than the cathode 12 and the electrolyte 17, and the electrolyte 17 i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com