Cooling system

A cooling system, coolant technology, used in liquid cooling, engine cooling, cooling/ventilation, etc., can solve problems such as damage, increase lubricating oil shear rate, increase tensile force, etc., to achieve effective operation and reduce warm-up time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

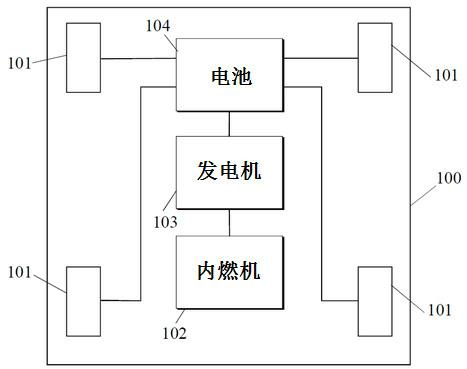

[0019] figure 1 A series hybrid vehicle 100 is shown having a plurality of in-wheel electric motors 101 , an internal combustion engine 102 , a generator 103 , and an energy storage device 104 such as a battery or capacitor.

[0020] The in-wheel electric motors 101 are configured to provide torque for driving the vehicle 100, as is well known to those skilled in the art. In general, in-wheel electric motors 101 may be integrated into at least two wheels (not shown) of vehicle 100 . For example, in a four-wheeled car, in-wheel electric motors can be integrated into all four wheels or into two wheels, preferably on the same axis.

[0021] An example of an in-wheel electric motor is described in patent application GB 2 440 251 .

[0022] Although this embodiment describes a series hybrid vehicle with an in-wheel electric motor, those skilled in the art should understand that the series hybrid vehicle according to an embodiment of the present invention can also use any form of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com