Stamping semi-cylindrical die

A semi-cylindrical and mold technology is applied in the field of manufacturing molds for molding semi-cylindrical molds, which can solve problems such as unfavorable environmental protection and damage to forest resources, and achieve the effects of reducing damage, uniform density, and beneficial to environmental protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Below in conjunction with accompanying drawing, the present invention is further described:

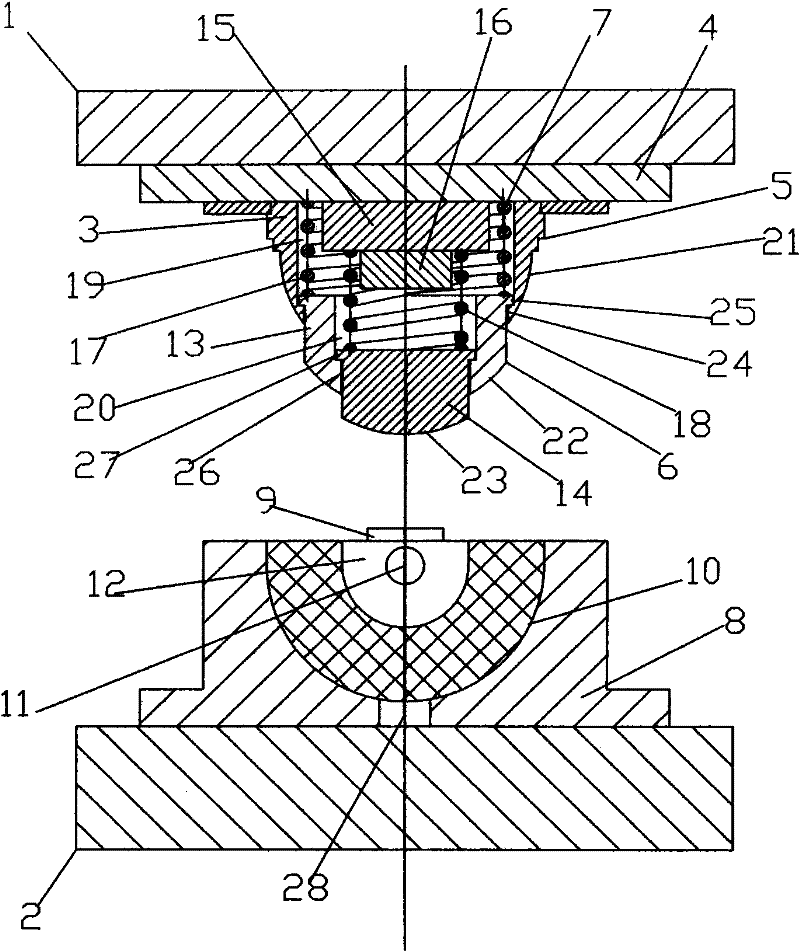

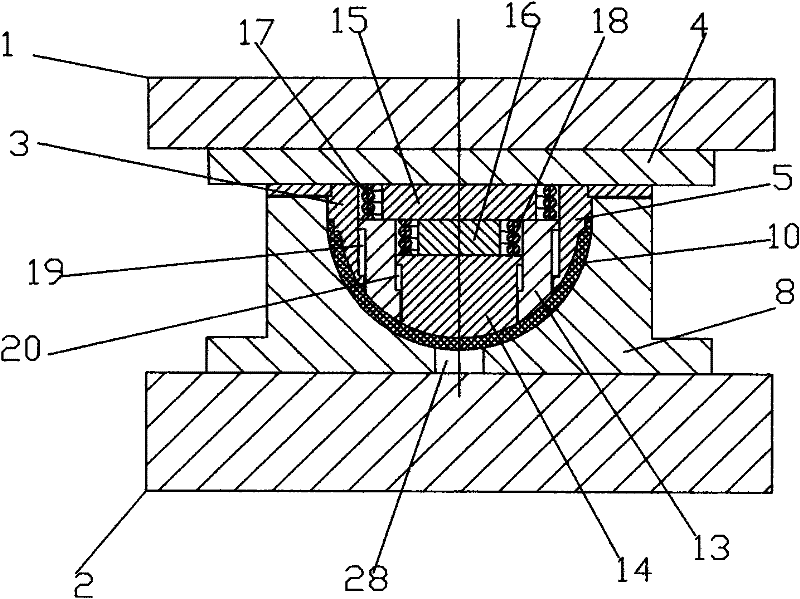

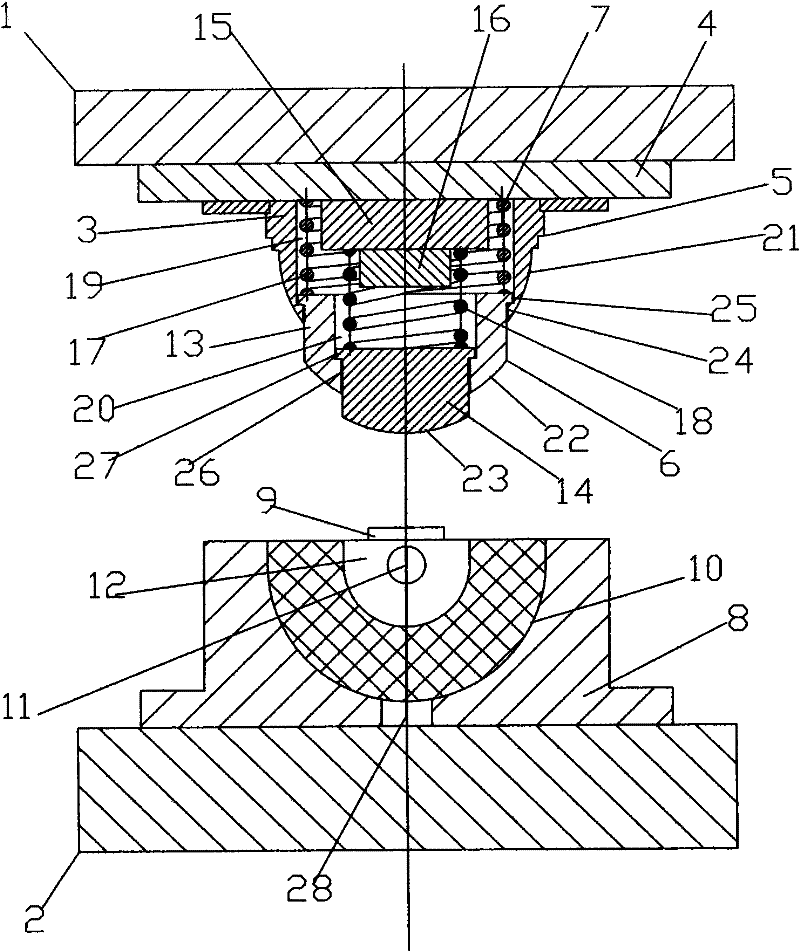

[0010] figure 1 The schematic diagram of the structure of the molded semi-cylindrical mold shown when it is not closed and figure 2 The schematic diagram of the structure of the molded semi-cylindrical mold shown when it is closed, the molded semi-cylindrical mold includes an upper mold 1 and a lower mold 2, the upper mold 1 is composed of a movable mold core 3 and an upper mold base 4; The base 5 is formed with a plurality of punch cores 6, the core base 5 is fixedly connected with the upper mold base 4, the punch core 6 is located in the core base 5, the punch core 6 and the core base 5 are dynamically connected, and the punch core 6 and the upper mold base 4 are provided with a compression spring 7; the lower mold 2 is composed of a lower mold base 8 and a blanking control device 9; the lower mold base 8 is provided with a blanking cavity 10, and the blanking control devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com