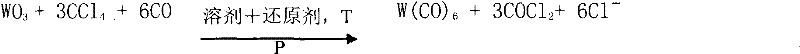

Method for directly synthesizing metal (tungsten or molybdenum) carbonyl complex from tungsten oxide or molybdenum oxide

A metal carbonyl and oxide technology, applied in the field of powder metallurgy, can solve the problems of harsh reaction conditions, low synthesis efficiency, complex process, etc., and achieve the effects of mild synthesis conditions, easy operation and high synthesis efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

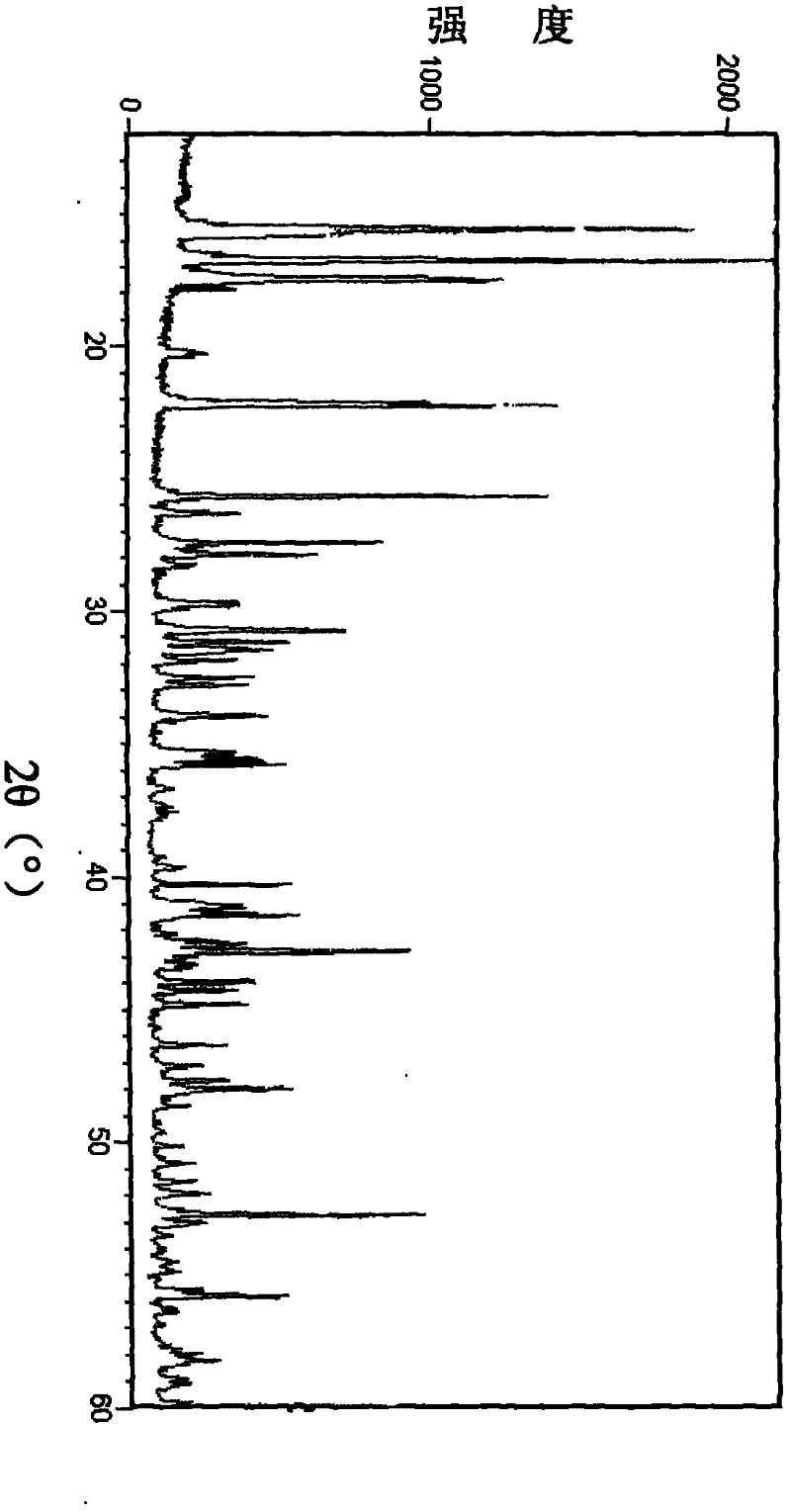

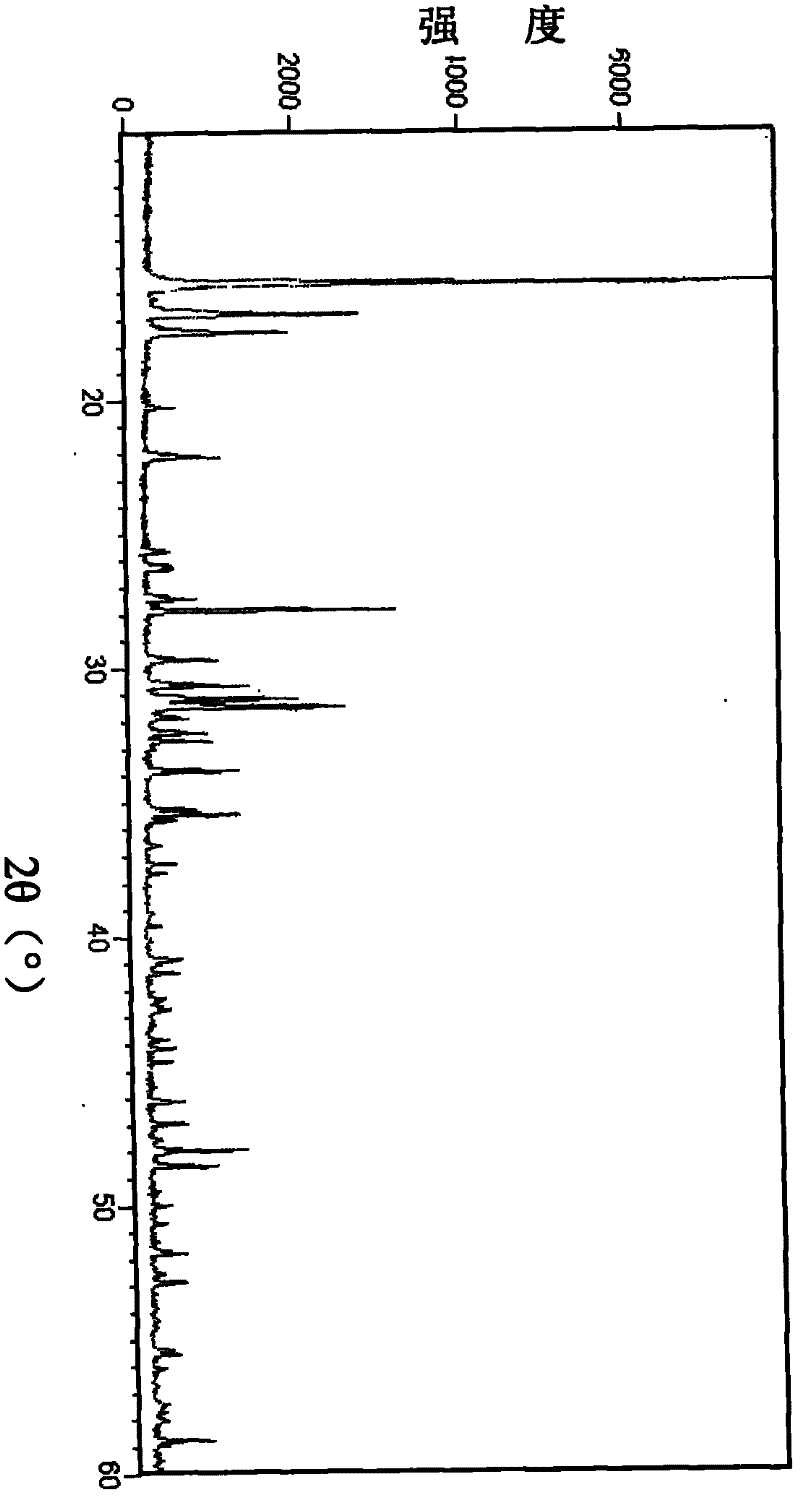

Embodiment 1

[0021] First, add a reducing agent (mass The percentages are 3%, 8%, 80%, 9% in turn); fill and place 2MPa carbon monoxide in the reaction kettle for 3 times to remove the air in the reaction system, then the reaction kettle is heated to 200 ° C and kept for 4 hours; the reaction system is to be After cooling to 30 ℃, feed carbon monoxide to 8MPa and keep the pressure, then open the reactor stirring device to break the encapsulated reducing agent container, the stirring speed is 100 rpm, and the reaction is continued for 1 hour; after the reaction is completed, the solution is cooled to room temperature Then, the reaction solution was taken out, and 10.9 g of colorless crystals of tungsten hexacarbonyl were obtained by distillation and heating sublimation, and the product yield was about 12%.

Embodiment 2

[0023] First, add a reducing agent (mass The percentages are 4%, 9%, 75%, 12% in turn); fill and place 2MPa carbon monoxide in the reaction kettle for 3 times to remove the air in the reaction system, then the reaction kettle is heated to 220 ° C and kept for 6 hours; After cooling to 40 ℃, feed carbon monoxide to 10MPa and keep the pressure, then open the reactor stirring device to break the encapsulated reducing agent container, the stirring speed is 150 rpm, and the reaction continues for 6 hours; after the reaction is completed, the solution is cooled to room temperature Then, the reaction solution was taken out, and 24.6 g of colorless crystals of tungsten hexacarbonyl were obtained by distillation and heating sublimation, and the product yield was about 27%.

Embodiment 3

[0025] First, add a reducing agent (mass The percentages are 5%, 10%, 70%, 15% in turn); fill and place 2MPa carbon monoxide in the reaction kettle for 3 times to remove the air in the reaction system, then the reaction kettle is heated to 250 ° C and kept for 8 hours; After cooling to 50°C, feed carbon monoxide to 20MPa and keep the pressure, then open the reactor stirring device to break the encapsulated reducing agent container, the stirring speed is 200 rpm, and the reaction is continued for 12 hours; after the reaction is completed, the solution is cooled to room temperature Then, the reaction solution was taken out, and 55.8 g of colorless crystals of tungsten hexacarbonyl were obtained by distillation and heating sublimation, and the product yield was about 46%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com