Sodium bismuth titanate-based high-strain lead-free piezoelectric ceramic and preparation method thereof

A sodium bismuth titanate-based, lead-free piezoelectric technology, applied in piezoelectric/electrostrictive/magnetostrictive devices, circuits, electrical components, etc., can solve the problem of low strain and achieve good performance and excellent pressure. The effect of improving electrical properties and sintering properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

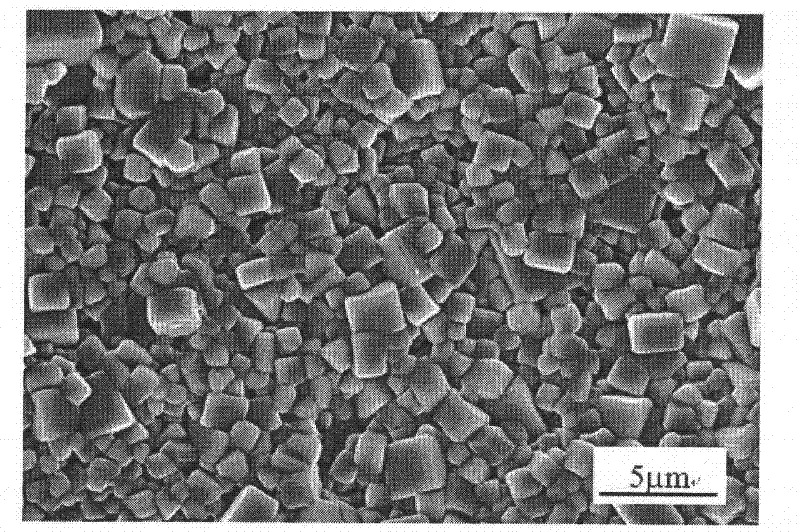

[0018] Example 1, to analyze pure BaCO 3 、 Bi 2 o 3 、TiO 2 , Li 2 CO 3 、Na 2 CO 3 As the base material, according to the stoichiometric ratio is 0.92Na 0.5 Bi 0.5 TiO 3 -0.08BaTiO 3 Ratio, accurate weighing. Then put the zirconia balls, material and ethanol into the ball mill jar according to the ratio of 3:1:1 and ball mill for 8 hours. The ground material is dried and pressed into large sheets, and pre-fired at 800°C for 5 hours. The calcined powder was ball milled for 8 hours and then sieved. The sieved powder is pre-pressed into a disc with a diameter of 12mm and a thickness of 1-1.5mm, and then finally shaped under an isostatic pressure of 100MPa. The molded wafer was kept at 1100° C. for 4 hours to obtain bismuth sodium titanate-based high-strain lead-free piezoelectric ceramics. After sintering into porcelain, it is ground and polished, then coated with silver paste, and kept at 550°C for 30 minutes to fire the silver electrode.

[0019] After the electri...

Embodiment 2

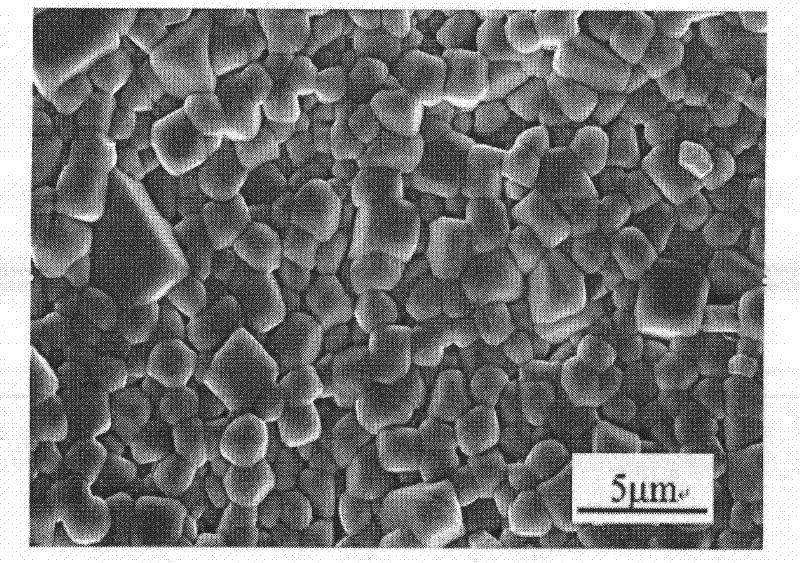

[0021] Example 2, to analyze pure BaCO 3 、 Bi 2 o 3 、TiO 2 , Li 2 CO 3 、Na 2 CO 3 As the base material, according to the stoichiometric ratio of 0.92 (Na 0.98 Li 0.02 ) 0.5 Bi 0.5 TiO 3 -0.08BaTiO 3 Ratio, accurate weighing. Then put the zirconia balls, material and ethanol into the ball mill jar according to the ratio of 3:1:1 and ball mill for 12 hours. The ground material is dried and pressed into large sheets, and pre-fired at 850°C for 4 hours. The calcined powder was ball milled for another 12 hours and then sieved. The sieved powder is pre-pressed into a disc with a diameter of 12mm and a thickness of 1-1.5mm, and then finally shaped under an isostatic pressure of 60MPa. The molded wafer was kept at 1125° C. for 3 hours to obtain bismuth sodium titanate-based high-strain lead-free piezoelectric ceramics. After sintering into porcelain, it is ground and polished, then coated with silver paste, and kept at 575°C for 25 minutes to burn the silver electrode....

Embodiment 3

[0024] Example 3, to analyze pure BaCO 3 、 Bi 2 o 3 、TiO 2 , Li 2 CO 3 、Na 2 CO 3 As the base material, according to the stoichiometric ratio of 0.92 (Na 0.91 Li 0.09 ) 0.5 Bi 0.5 TiO 3 -0.08BaTiO 3 Ratio, accurate weighing. Then put zirconia balls, material and ethanol into a ball mill jar in a ratio of 3:1:1 for ball milling for 10 hours. The ground material is dried and pressed into large sheets, and pre-fired at 900°C for 3 hours. The calcined powder was then ball milled for 10 hours and then sieved. The sieved powder is pre-pressed into a disc with a diameter of 12mm and a thickness of 1-1.5mm, and then finally shaped under an isostatic pressure of 20MPa. The molded wafer was kept at 1150° C. for 2 hours to obtain bismuth sodium titanate-based high-strain lead-free piezoelectric ceramics. After sintering into porcelain, it is ground and polished, then coated with silver paste, and kept at 600°C for 20 minutes to burn the silver electrode.

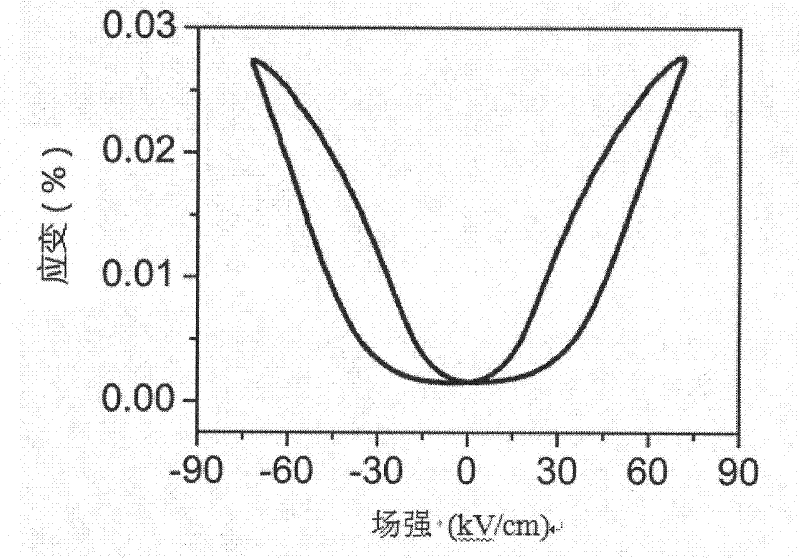

[0025] After t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com