Preparation method of amorphous silicon boron-carbon-nitrogen-aluminum powder material

A silicon-boron-carbon-nitride-aluminum powder material technology, which is applied in the field of silicon-boron-carbon-nitride aluminum powder preparation, can solve problems such as complex process, difficult control, and low output, and achieve simple preparation process, low cost, and high output Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

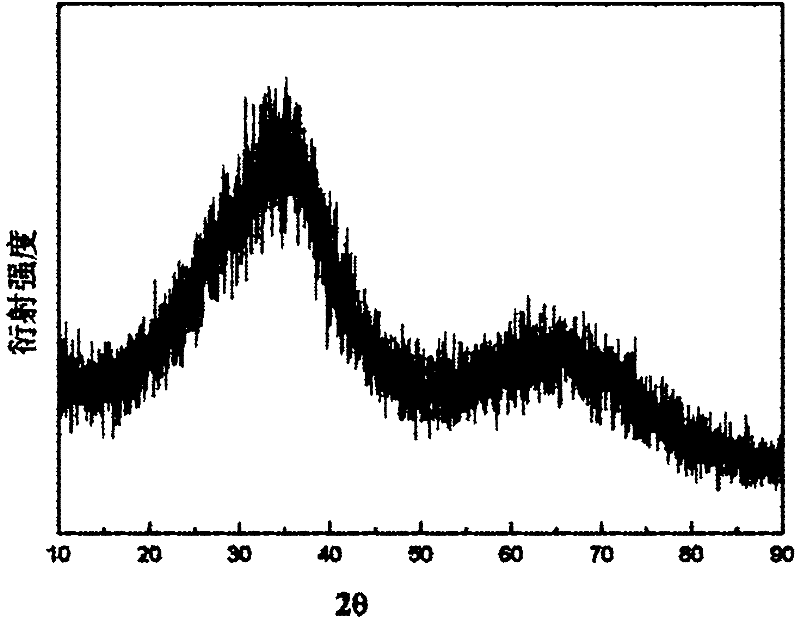

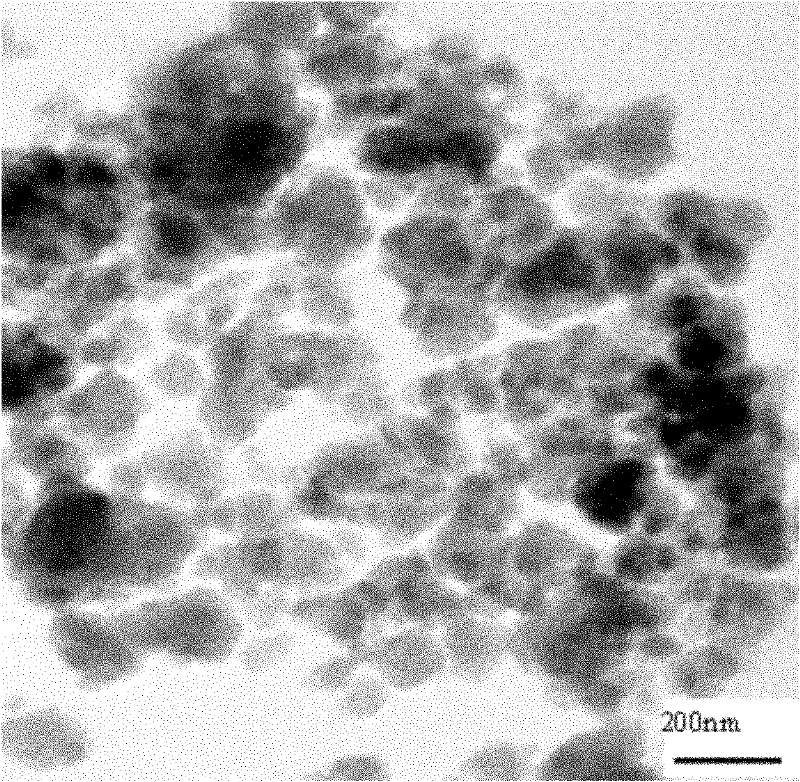

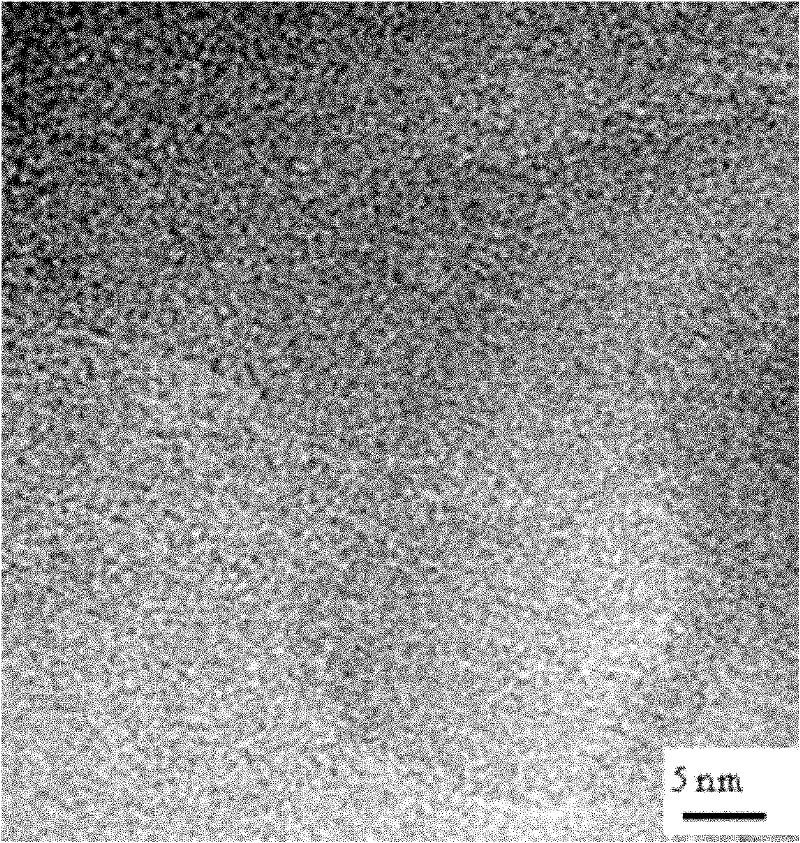

[0011] Specific embodiment one: the preparation method of the amorphous silicon boron carbon nitrogen aluminum powder material of this embodiment is carried out according to the following steps: one, take the cubic silicon powder (c-Si) that purity is 99%~99.9%, purity is 98 % to 99.9% hexagonal boron nitride (h-BN), graphite (C) with a purity of 99% to 99.9%, and aluminum nitride powder (AlN) with a purity of 98% to 99.9% as raw materials. The molar ratio is Si: BN: C: AlN=1: 0.5: 1.5: 0.3; 2. In the glove box, put the weighed raw materials and silicon nitride grinding balls into a silicon nitride ball mill jar together, and the silicon nitride After the ball mill tank is sealed, take it out from the glove box, and then install it on a planetary ball mill for ball milling for 10-100 hours, then put the silicon nitride ball mill tank in the glove box to take powder, and the powder taken out is amorphous silicon borocarbon nitrogen Aluminum powder;

[0012] Wherein the particl...

specific Embodiment approach 2

[0014] Specific embodiment two: the difference between this embodiment and specific embodiment one is that in step one, it is also possible to weigh cubic silicon powder with a purity of 99% to 99.9%, hexagonal boron nitride with a purity of 98% to 99.9%, and 99%-99.9% graphite and 99%-99.9% pure aluminum powder (Al) are raw materials, wherein the molar ratio of each raw material is Si:BN:C:Al=1:0.5:1.5:0.3. Other steps and parameters are the same as in Embodiment 1

specific Embodiment approach 3

[0015] Embodiment 3: The difference between this embodiment and Embodiment 1 is that in step 2, it is installed on a planetary ball mill for ball milling for 10 hours. Other steps and parameters are the same as those in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com