Preparation method of photonic crystal inverse opal film

A technology of inverse opal and photonic crystal, which is applied in the field of preparation of photonic crystal inverse opal thin film, which can solve the problems of few photonic crystals in the light band, limited material varieties, narrow photonic band gap, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0115] The present invention will be further described below in conjunction with accompanying drawing:

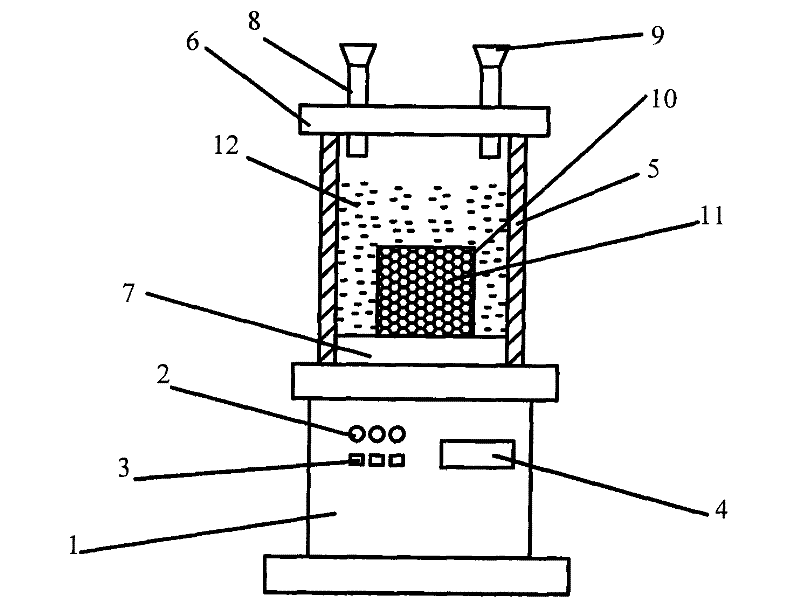

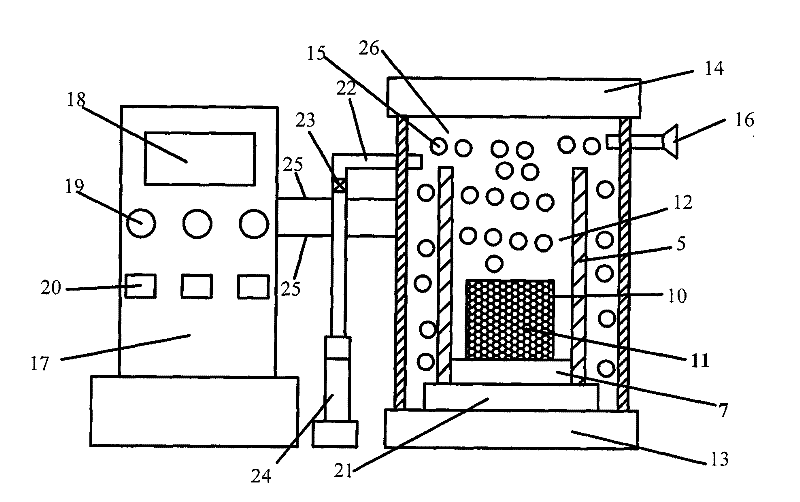

[0116] figure 1 As shown, it is a state diagram for the preparation of an inverse opal film. The preparation is carried out in a ceramic container. The ceramic container 5 is placed on the electric heater 1. A platform 7 is provided in the ceramic container 5, and the carbon dioxide is vertically placed on the platform 7. Silicon substrate 10, the front and back of silicon dioxide substrate 10 are prepared inverse opal film layer 11, in ceramic container 5 is tantalum pentachloride ethanol solution 12, tantalum pentachloride ethanol solution 12 submerges the silicon dioxide substrate sheet 10; the upper part of the ceramic container 5 is a container cover 6, and the upper part of the container cover 6 is provided with outlet pipes 8, 9; the electric heater 1 is provided with a display screen 4, an indicator light 2, and a switch 3; After the positive opal film layer is pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com