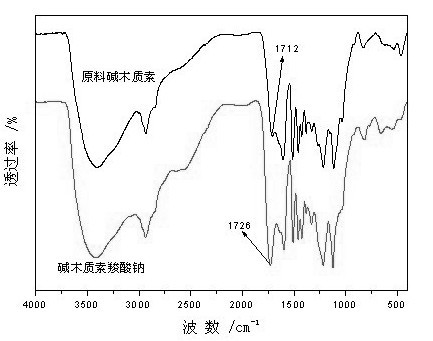

Water-soluble alkali lignin carboxylate and preparation method thereof

A technology of alkali lignin and carboxylate, which is applied in the field of water-soluble alkali lignin carboxylate and its preparation, can solve the problems of poor water solubility of products, increased content of carboxylic acid groups in difficult lignin, and high cost, and achieve broadening research Range, easy operation control, rich variety and application range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Take 200 grams of alkaline pulping straw pulp black liquor acid analysis alkali lignin (by weight percentage, solid content of 95%) and mix it with 400 grams of water, add sodium hydroxide to adjust the pH to 9.5, and then heat to 60 ℃, stir and dissolve fully, add 20 g of dimethylformamide, and perform an activation reaction at 75 ℃ for 1 hour to obtain a reaction solution. Dissolve the mixture of 10 grams of monochloroacetic acid and 5 grams of sodium monochloroacetate in 60 grams of water, add sodium hydroxide to adjust the pH to 8, and then add it dropwise to the reaction solution within 30~60 minutes for electrophilic substitution reaction. , adjust the pH to 10 with sodium hydroxide, and react at 70° C. for 3 hours after the dropwise addition is completed.

[0030] (2) Dissolve 25 grams of monochloroacetic acid in 55 grams of water, then add sodium hydroxide to adjust the pH to 8, and then add it dropwise to the reaction solution obtained in step (1) within 30...

Embodiment 2

[0032](1) Take 200 grams of alkaline pulping black liquor straw pulp acid analysis alkali lignin (in terms of weight percentage, solid content of 95%) and mix it with 433 grams of water, add sodium hydroxide to adjust the pH to 10, and then heat to 70 ℃ stirring and dissolving fully, adding 30 g of dimethylacetamide, and performing an activation reaction at 80 ℃ for 0.5 hours to obtain a reaction solution. Dissolve 30 grams of monobromoacetic acid in 70 grams of water, add sodium hydroxide to adjust the pH to 8, and then drop it into the reaction solution within 30 minutes to carry out electrophilic substitution reaction. During the dropwise addition, adjust the pH of the reaction solution with sodium hydroxide. The pH was 9.5, and after the dropwise addition was completed, the reaction was carried out at 60° C. for 2 hours.

[0033] (2) Dissolve 45 grams of monobromoacetic acid in 105 grams of water, then add sodium hydroxide to adjust the pH to 8, and then drop it into the r...

Embodiment 3

[0035] (1) Take 200 grams of alkaline pulping bamboo pulp black liquor acid analysis alkali lignin (in terms of weight percentage, solid content of 93%) and mix it with 400 grams of water, add sodium hydroxide to adjust the pH to 10.5, and then heat to 60 ℃ stirring and dissolving fully, adding 35 g of acetone, and performing an activation reaction at 85 ℃ for 1 hour to obtain a reaction liquid. Dissolve 21 grams of monoiodoacetic acid in 50 grams of water, add sodium hydroxide to adjust the pH to 8.5, and then drop it into the reaction solution within 60 minutes to carry out electrophilic substitution reaction. During the dropwise addition, adjust the pH of the reaction solution with sodium hydroxide. The pH was 10.5. After the dropwise addition was completed, the reaction was carried out at 75°C for 1.5 hours.

[0036] (2) Dissolve 49 grams of monoiodoacetic acid in 100 grams of water, then add sodium hydroxide to adjust the pH to 8.5, and then drop it into the reaction solu...

PUM

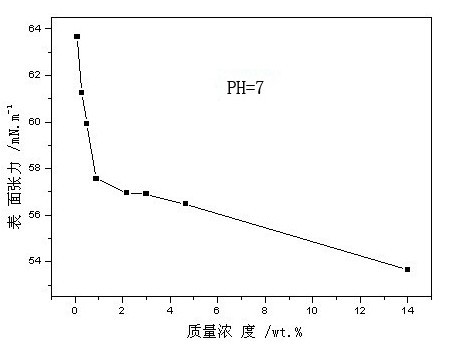

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com