Decoupling-type constant-pressure oil chamber double-cylinder pneumatic spring

A technology of oil-gas spring and oil cylinder, which is applied in the field of new structure of oil-gas spring, can solve the problems of high cost, high requirement of sealing device, complex structure, etc., and achieve the effect of low cost, lower sealing requirement and easy realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

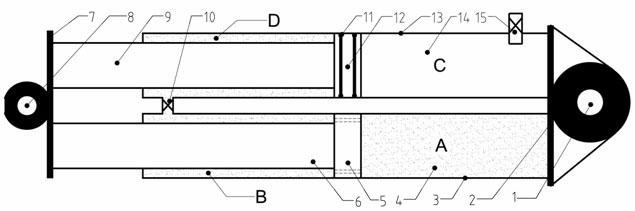

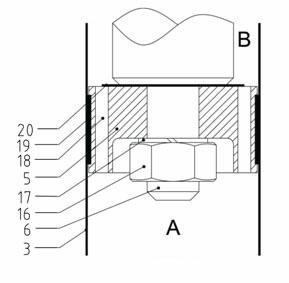

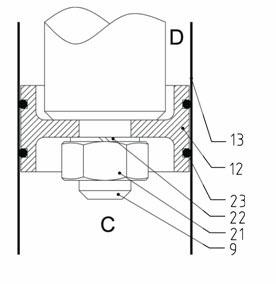

[0017] like figure 1 As shown, the atmospheric pressure oil chamber double-cylinder oil and gas spring includes a cylinder lifting ring 1, a cylinder base 2, an oil cylinder 3, an oil 4, an oil cylinder piston 5, an oil cylinder piston rod 6, a piston rod connecting plate 7, a piston rod lifting ring 8, The cylinder piston rod 9, the communication pipe 10, the cylinder piston seal 11, the cylinder piston 12, the cylinder 13, the nitrogen gas 14, the gas valve 15, etc. The oil cylinder 3 and the cylinder 13 are arranged side by side. The oil cylinder 3 is divided into a compression chamber A and an expansion chamber B by the oil cylinder piston 5, and the oil cylinder piston 5 is machined with a corresponding damping channel. The cylinder 13 is divided into an air pressure chamber C and a compensation chamber D by the cylinder piston 12, and the cylinder piston 12 is sealed by the cylinder piston seal 11, thereby isolating the nitrogen in the air pressure chamber C and the oil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com