Igniting method for gasification furnace start-up burner

A technology for start-up burners and gasifiers, which is applied to combustion methods, burners, and controlled combustion. It can solve problems such as failure to ignite, easy burnout of start-up burners, and difficulty in igniting coal burners, so as to reduce the number of ignition failures. , Improve the success rate of driving and the effect of improving the success rate of ignition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

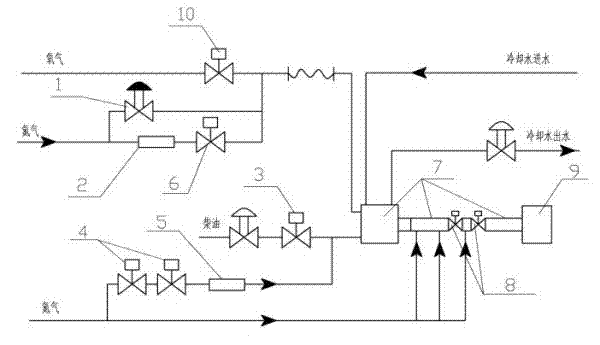

[0015] Example 1 : For the ignition method of the gasification furnace start-up burner, see figure 1 , before the start-up burner is ignited, the start-up burner valve 8 is opened, and the start-up burner 7 is put into the hearth of the gasifier 9 .

[0016] Open the first nitrogen shut-off valve 6 and the second nitrogen valve 4 to purge the start-up burner, and observe the flow of the first nitrogen flowmeter 2 and the second nitrogen flowmeter 5 at the same time. In the case of blockage and no leakage, control the flow of the second nitrogen flow meter 5 to 450 Nm 3 / h, the flow rate of the first nitrogen flow meter 2 is 3200 Nm 3 / h, the duration of nitrogen purge burner is 30-40s.

[0017] After purging, start the ignition of the burner, first open the oxygen valve 10 to feed pure oxygen, open the diesel valve 3 to feed diesel, and gradually adjust the opening of the first nitrogen regulating valve 1, when the valve opening is 0.9% At about 0.02 kg / s, the flow rate o...

Embodiment 2

[0020] Example 2 : basically the same as Embodiment 1, the difference is:

[0021] During the ignition process of the start-up burner, adjust the opening of the first nitrogen regulating valve 1 to 0.3%, the nitrogen flow rate to 0.01kg / s, the oxygen flow rate to 1.15kg / s, and the diesel flow rate to 0.3kg / s.

Embodiment 3

[0022] Example 3 : basically the same as Embodiment 1, the difference is:

[0023] During the ignition process of the start-up burner, adjust the opening of the first nitrogen regulating valve 1 to 3%, the nitrogen flow rate to 0.05 kg / s, the oxygen flow rate to 1.40 kg / s, and the diesel flow rate to 0.45 kg / s.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com