Mixing combustion guide coupling structure of combustion chamber

A coupling structure and combustion chamber technology, applied in the direction of combustion chamber, continuous combustion chamber, combustion method, etc., can solve the problems of increasing the length and weight of the engine, reducing the overall performance of the engine, and complex structure, so as to reduce pressure loss and increase thrust Ratio, the effect of improving cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

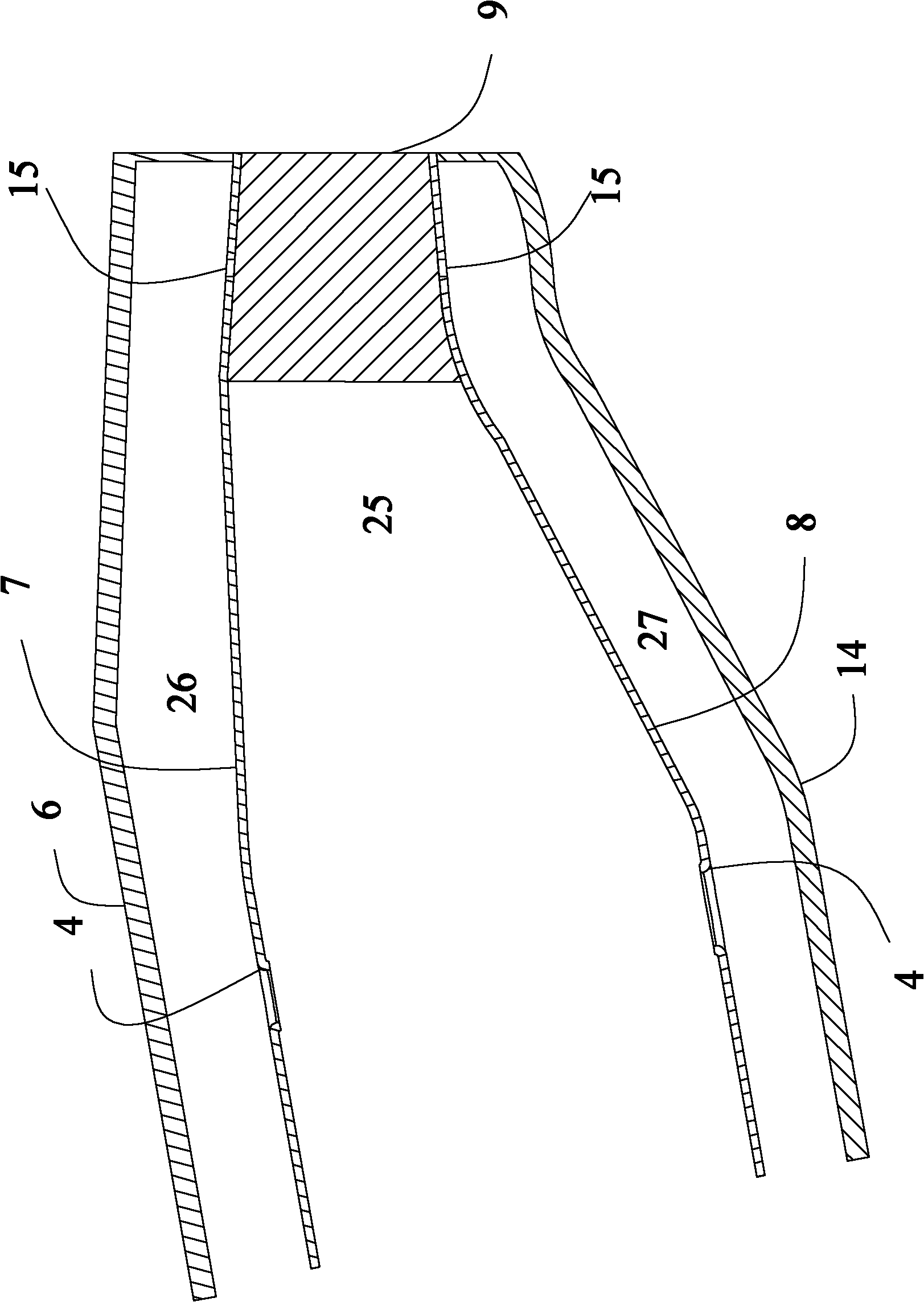

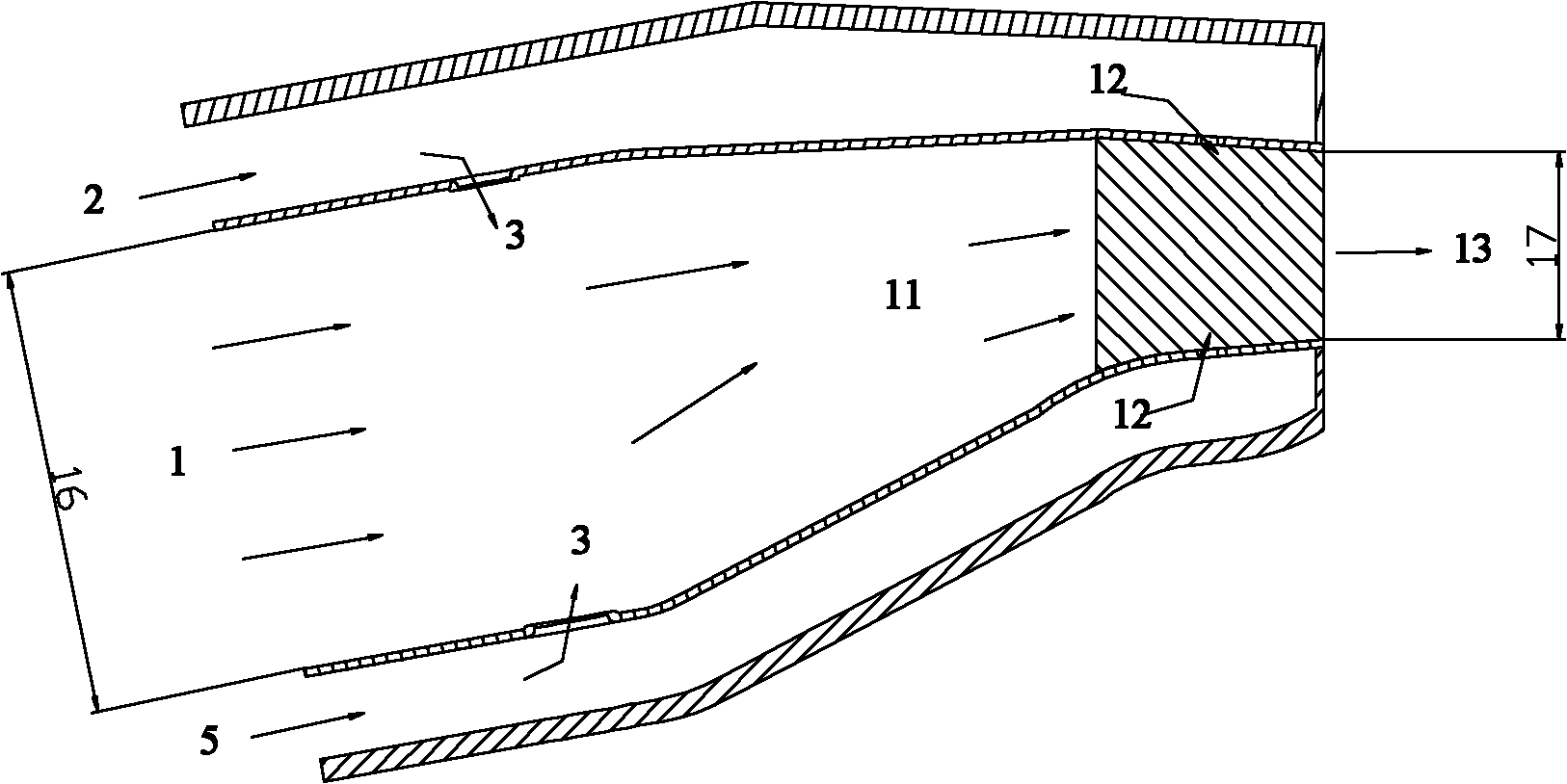

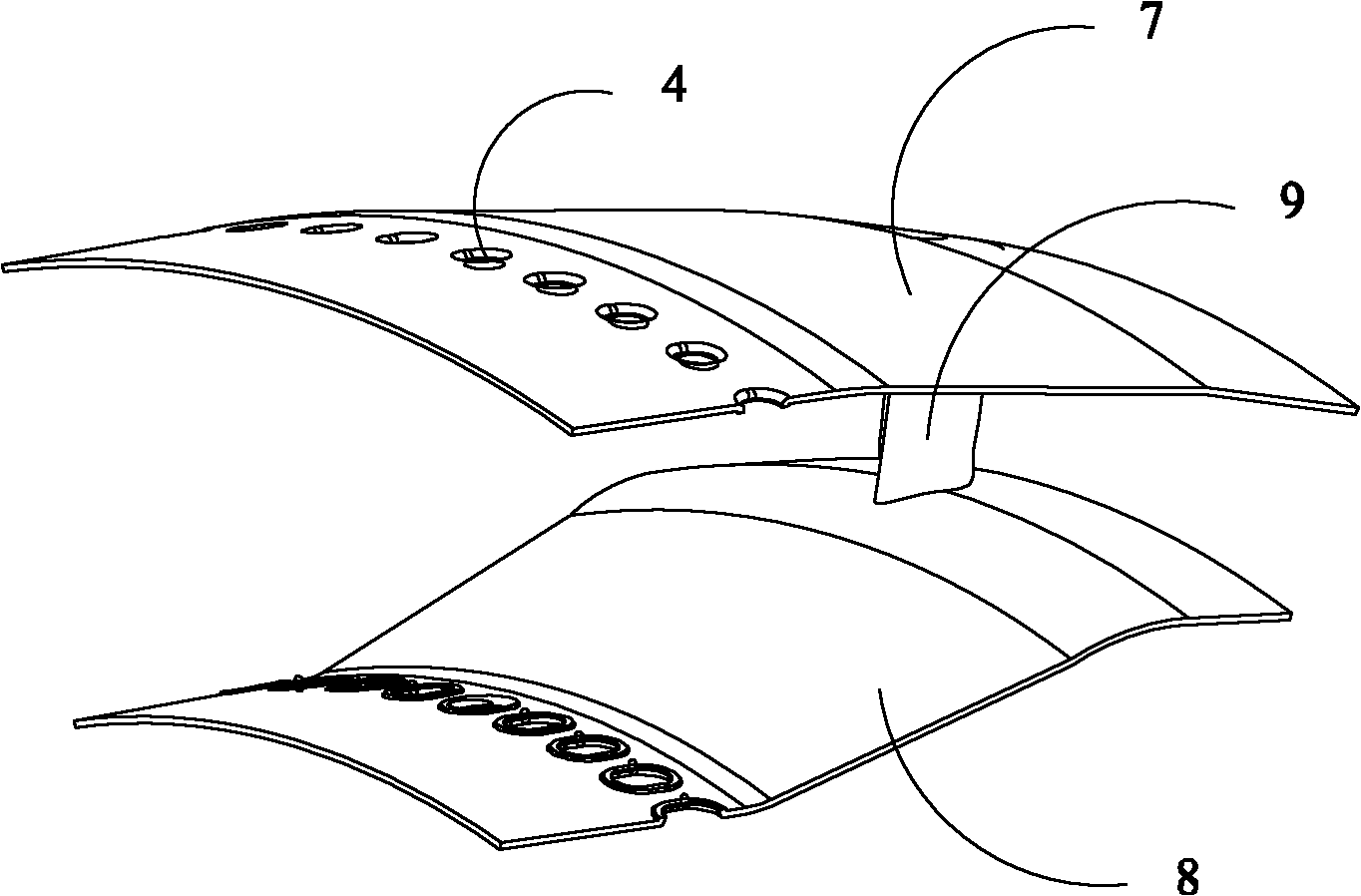

[0028] Such as figure 1 , 2 , shown in 3, the present invention is made of outer casing 6, inner casing 14, outer flame barrel 7, inner flame barrel 8 and turbine deflector vane 9, the outlet of outer flame barrel 7 and inner flame barrel 8 flame barrel is connected with machine The outlet of the box is fixedly connected.

[0029] Such as figure 1 , shown in 2, 3, and 4, the outer casing 6 and the inner casing 14, the inner flame cylinder 8 and the outer flame cylinder 7 are annular structures; The mixing hole 4 to the direction; the outer combustion chamber 26 is formed between the outer casing 6 and the outer flame cylinder 7, and the combustion inner annular chamber 27 is formed between the inner casing 14 and the inner flame cylinder 8; the turbine guide The blades 9 are evenly arranged in the shrinkage passage 25 between the outer flame tube 7 and the inner flame tube 8 along the circumferential direction, and the turbine guide blades 9 and the mixing holes 4 are at th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com