Base materials of PTC (Positive Temperature Coefficient) thermistor, PTC thermistor and preparation method thereof

A technology of thermistor and substrate, applied in the direction of resistors with positive temperature coefficient, etc., can solve the problems of personnel and environmental damage, PTC components can not work normally, etc., to achieve the effect of a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] Prepare the preparation method of the base material of PTC thermistor of the present invention, comprise the following steps:

[0046] Step 1: According to the relative weight ratio, mix 80-150 parts of conductive particles, 20-100 parts of inert filler, 0.5-3 parts of crosslinking agent, 0-1 part of nucleating agent, 0.5-5 parts of sensitizer, antioxidant 0.5-3 parts, lubricant 0.5-2 parts, coupling agent 0-2 parts, after weighing, pre-mix first;

[0047] Step 2: Control the temperature of the two rollers of the two-roll mill at 190-290°C, then add 100 parts of polyamide resin between the two rollers to completely melt the resin, and then disperse and premix the mixture evenly in step 1 Put the material into the roller of the double-roller mill to make it fully mixed with the molten polyamide resin, and keep turning the material to achieve the purpose of fully melting and mixing. The mixing time is 20 minutes, and finally the sheet is discharged. The thickness of the ...

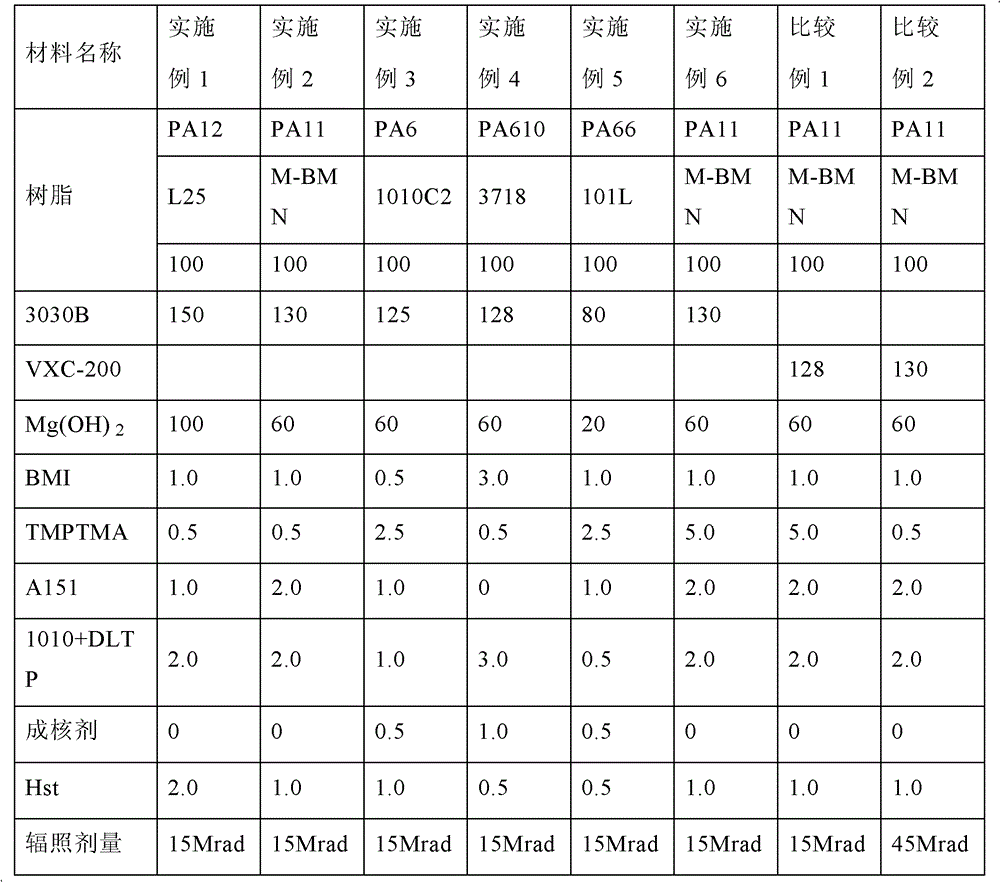

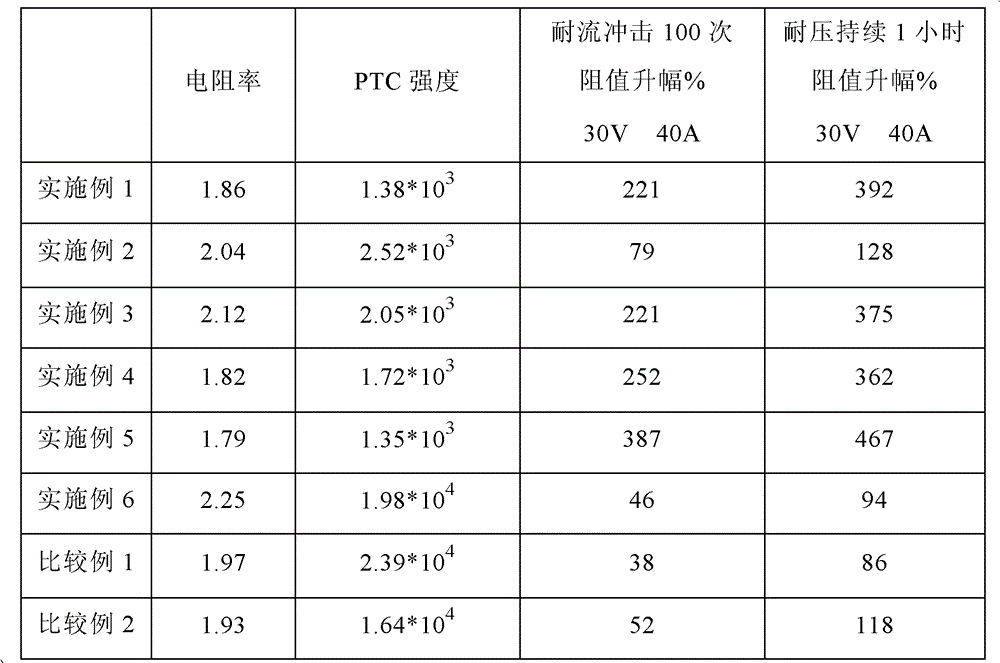

Embodiment 1

[0057] Take by weighing polyamide resin PA12 (Swiss EMS company, melting point 178 ℃, density 1.01g / cm2) 100g, antioxidant 2g is made of tetrakis [methyl-β-(3,5-di-tert-butyl-4-hydroxybenzene base) propionate] pentaerythritol ester (1010) 1.5g and auxiliary antioxidant dilauryl thiodipropionate (DLTP) 0.5g, combined at a fixed ratio of 3:1, the crosslinking agent is bismaleic acid Imide (BMI) 1.0g, coupling agent is silane coupling agent vinyltriethoxysilane (A151) 1.0g, lubricant is stearic acid (Hst), adding amount is 2.0g, sensitizer Trimethylolpropane trimethacrylate (TMPTMA), the addition is 0.5g, the conductive particle is carbon black (Mitsubishi Conductive Carbon Black 3030B), the addition is 150g, and the inert filler is magnesium hydroxide Mg(OH) 100g;

[0058] Control the roll temperature of the two-roll mill at 190°C, first add polyamide resin PA12 into the mill, and add carbon black, fillers, antioxidants, cross-linking agents and other additives after it is comp...

Embodiment 2

[0060] Switch the resin to polyamide PA11 (French Atofina M-BMN, melting point 186°C, density 1.07g / cm2), and the antioxidant consists of tetrakis[methyl-β-(3,5-di-tert-butyl-4 -Hydroxyphenyl) propionate] pentaerythritol ester (1010) 1.5g and auxiliary antioxidant dilauryl thiodipropionate (DLTP) 0.5g composition, totally 2.0g, crosslinking agent bismaleimide ( BMI) is 1.0g, coupling agent vinyltriethoxysilane (A151) is 2.0g, lubricant stearic acid (Hst) is 1.0g, sensitizer trimethylolpropane trimethacrylate (TMPTMA ) is 0.5g, conductive particle carbon black (3030B) is 130g, and the inert filler is 60g of magnesium hydroxide;

[0061] The processing technology and method are the same as in Example 1, and the temperature of the double-rollers for refining is set to 200°C, and the molding temperature is set to 210°C, and its properties are shown in Table 2;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com