Method for making barbecued roast beef

A production method, the technology of beef fork, which is applied in the production of beef fork pork and stewed sauce products, can solve the problems of affecting the food quality of products, thick beef fiber, and limited production capacity, etc., and achieve the effect of short production cycle, long shelf life and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

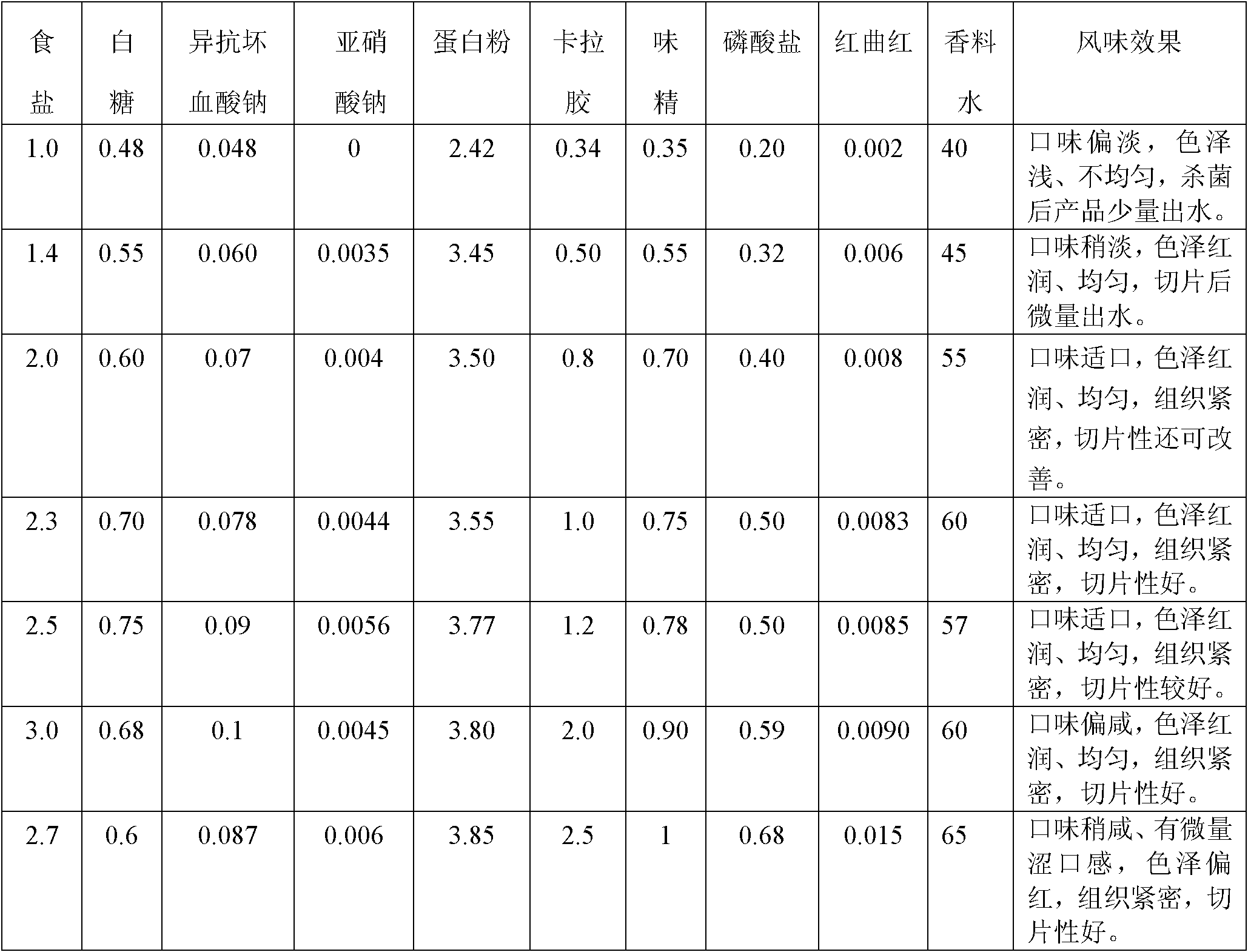

Image

Examples

Embodiment 1

[0028] 1. Thaw and divide

[0029] Take the beef at the center temperature of -2℃~0℃, clean the excess fat on the surface of the beef, 0%<fat content≤3%, and cut into blocks with a weight of 200-300g, the block shape is complete, no edges and corners are not loose. The processed meat should be free of hairs, bones, larger tendons, coarse tissue membranes, wounds, congestion, lymph, and impurities. The meat temperature after trimming is ≤8℃.

[0030] 2. Injection

[0031] 2.1 Boil the spice water

[0032] The spice water used for injection is boiled one day in advance. The specific method is: pour tap water into the jacketed pot. After the water is boiled, put the spice bag in the water. After boiling for 1.5 hours, pour the brine and the spice bag into the bucket cart , Placed in the marinating warehouse at 0~4℃ for cooling and standby; the formula of spice water is star anise, pepper, cumin, cinnamon, bay leaf, clove and water, weights are 0.084kg, 0.028kg, 0.056kg, 0.084kg, 0.028k...

Embodiment 2

[0050] 1. Thaw and divide

[0051] Take the beef at the center temperature of -2℃~0℃, clean the excess fat on the surface of the beef, 0%<fat content≤3%, and cut into blocks with a weight of 200-300g, the block shape is complete, no edges and corners are not loose. The processed meat should be free of hairs, bones, larger tendons, coarse tissue membranes, wounds, congestion, lymph, and impurities. The meat temperature after trimming is ≤8℃.

[0052] 2. Injection

[0053] 2.1 Boil the spice water

[0054] The spice water used for injection is boiled one day in advance. The specific method is: pour tap water into the jacketed pot. After the water is boiled, put the spice bag in the water, boil for 2 hours, pour the brine and the spice bag into the bucket cart , Placed in the marinating warehouse at 0~4℃ for cooling and standby; the formula of spice water is star anise, pepper, cumin, cinnamon, bay leaf, clove and water, weights are 0.09kg, 0.02kg, 0.06kg, 0.09kg, 0.02kg respectively ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com