Method and device for removing dust in flue gas

A flue gas and dust technology, applied in the field of electrostatic dust removal methods and devices, can solve the problems of low removal rate of fine particles, failure to charge, and low collection efficiency, so as to enhance charging and collection performance, and reduce vibration secondary The effect of non-flying and good dust adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

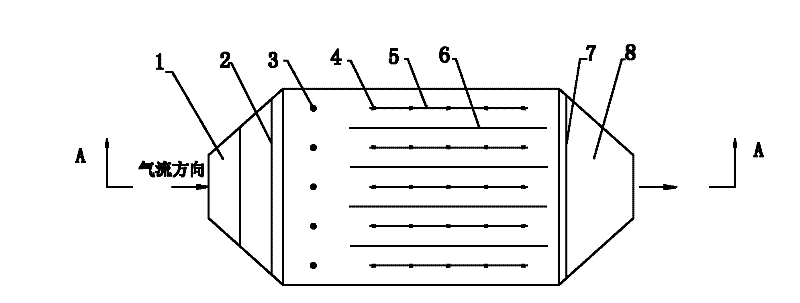

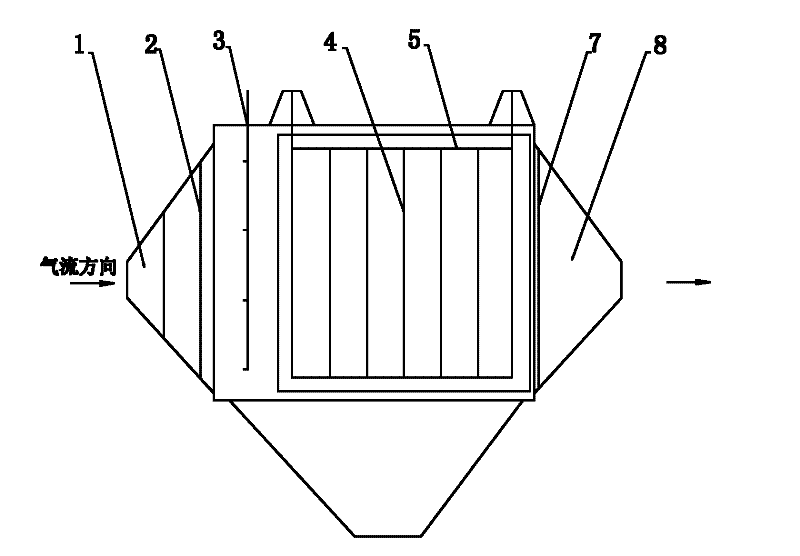

[0019] Below in conjunction with accompanying drawing, structure of the present invention, principle and working process are further described:

[0020] figure 1 and figure 2 The structure of the fume dedusting device provided by the present invention is shown. The dedusting device includes an intake fume box 1, an air distribution plate 2, an electrostatic atomizing nozzle 3, a dust collecting electric field, a grooved plate 7, an exhaust fume box 8 and Ash hopper, etc., the dust collecting electric field is provided with a pole line 4 and a dust collecting pole plate 6, the pole line is connected to the DC negative high voltage, and the dust collecting pole plate is grounded; among which the pole line can be RS barbed wire, spiral wire or a plate with weak discharge Shaped barbed wire, the dust collector plate can be a large C-shaped plate or a corrugated plate. At least one group of electrostatic atomizing nozzles is arranged between the air distribution plate and the du...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com