Method for preventing interface of stainless steel compound plate subjected to vacuum composite rolling from being oxidized

A technology of clad rolling and stainless steel plate, applied in the direction of metal rolling, metal rolling, manufacturing tools, etc., can solve the problems of interface plasticity effect of clad plate, weaken interface bonding performance, decrease corrosion resistance, etc., to eliminate decarburization and chromium-rich layer, solve the problem of element diffusion, and improve the effect of shear strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

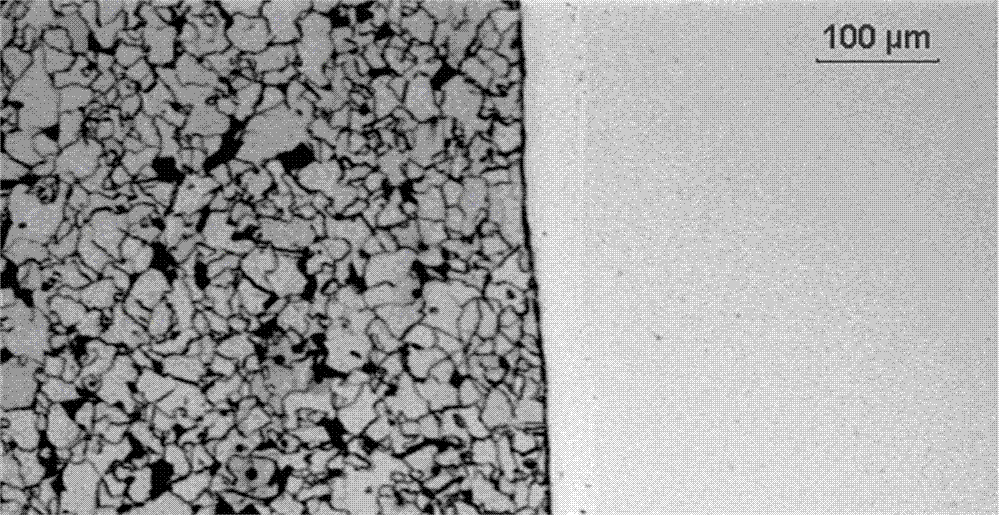

[0027] The size of the stainless steel plate material is 500×200×2mm, and the size of the carbon steel plate material is 500×200×10mm. The rust layer and the oxide layer on one side of the two stainless steel plate materials are respectively removed, and then the rust layer and the oxide layer are removed. The side of the oxide layer is cleaned with ethanol and dried; the rust layer and the oxide layer on the two sides of a carbon steel plate material are removed, and then the side with the rust layer and the oxide layer is cleaned with ethanol and dried;

[0028] The stainless steel plate material and carbon steel plate material are stacked alternately, and the adjacent stainless steel plate material and carbon steel plate material are separated by nickel foil, and the two sides of the nickel foil are respectively connected with the cleaned side of the stainless steel plate material and the carbon steel plate material The cleaned sides of the materials are connected, and the s...

Embodiment 2

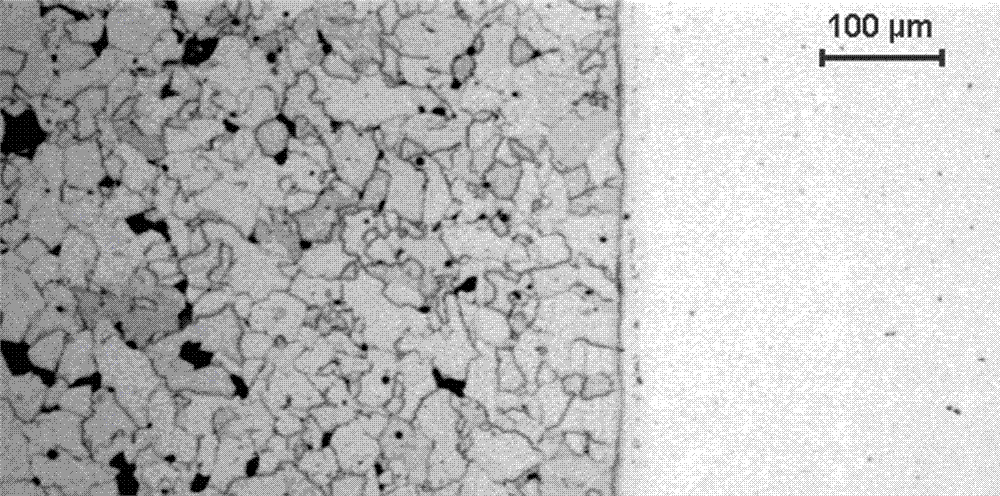

[0036] The size of the stainless steel plate material is 1000×200×4mm, and the size of the carbon steel plate material is 1000×200×10mm. The rust layer and the oxide layer on one side of the two stainless steel plate materials are respectively removed, and then the rust layer and the oxide layer are removed. The side of the oxide layer is cleaned with acetone and blown dry; the rust layer and the oxide layer on the two sides of a carbon steel plate material are removed, and then the side where the rust layer and the oxide layer are removed is cleaned with acetone and dried;

[0037] The stainless steel plate material and carbon steel plate material are stacked alternately, and the adjacent stainless steel plate material and carbon steel plate material are separated by nickel foil, and the two sides of the nickel foil are respectively connected with the cleaned side of the stainless steel plate material and the carbon steel plate material The cleaned sides of the materials are c...

Embodiment 3

[0044] The size of the stainless steel plate material is 500×200×1mm, the size of the carbon steel plate material is 500×200×10mm, respectively remove the rust layer and the oxide layer on one side of the stainless steel plate material and the carbon steel plate material, and then remove the rust layer and the sides of the oxide layer were cleaned with ethanol and dried;

[0045] The stainless steel plate material and the carbon steel plate material are stacked alternately, and the stainless steel plate material and the carbon steel plate material are separated by nickel foil, and the two sides of the nickel foil are respectively connected with the cleaned side of the stainless steel plate material and the carbon steel plate material after cleaning The side of the stainless steel plate material and the side of the carbon steel plate material are overlapped with the side of the nickel foil to make a composite blank consisting of 2 layers of steel plate material and 1 layer of ni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com