Friction material for preparing NAO brake pad

A friction material and brake pad technology, applied in the field of automobile brake pads, can solve the problems of dirty appearance of the wheel hub, color pollution of the wheel hub, braking noise of the brake pad, etc., and achieve the effect of good visual effect, low wear rate and stable braking effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Ceramic fiber 5%, mineral fiber 15%, resin 10%, chalcocite powder 6%, graphite 10%, barium sulfate 18%, biological calcification particles 5%, coke 5%, friction reducing agent 10%, performance adjustment Agent 5%, filler 11%, total 100%.

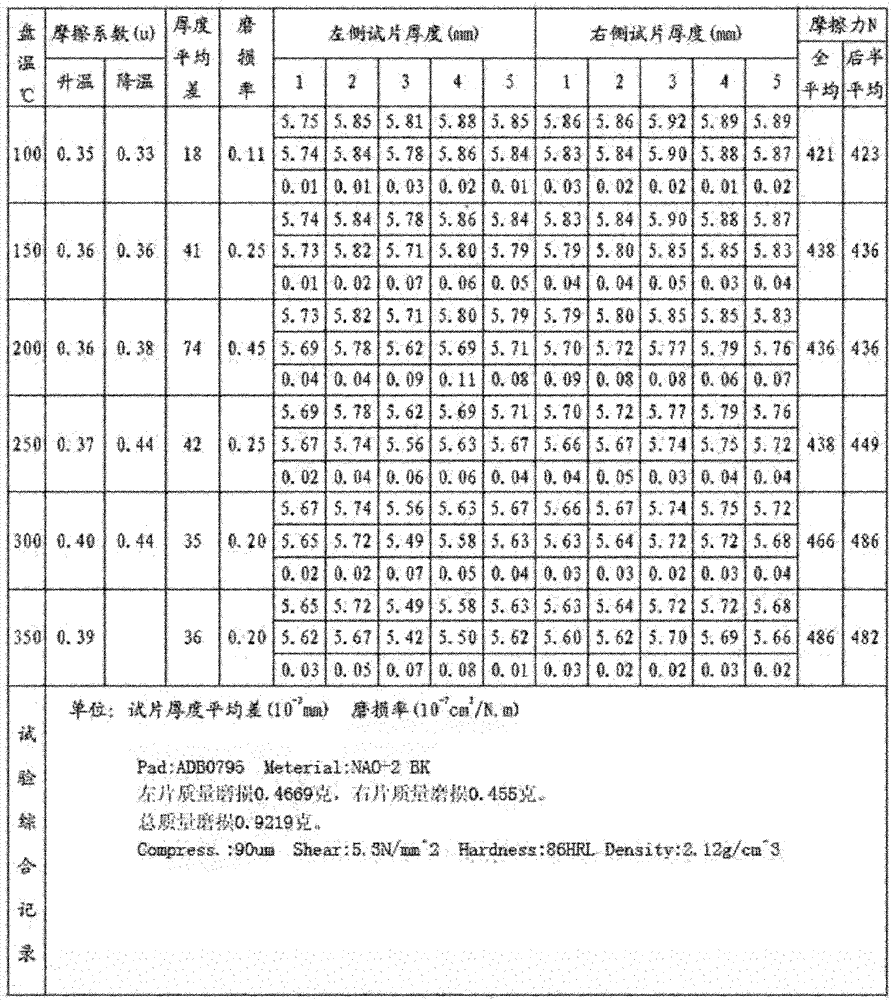

[0023] The above-mentioned materials were made into brake pads according to the conventional pressing method, and tested according to 4 types on a fixed-speed testing machine according to the GB5763-2008 standard. The results are shown in Table 1.

[0024] Table 1:

[0025]

[0026] It can be seen from the data in Table 1 that the friction coefficient of the friction material obtained in Example 1 of the present invention changes little. In the heating stage, the friction coefficient is between 0.35-0.40, and in the cooling stage, the friction coefficient is between 0.33-0.44, and the wear rate is small, stable at 0.11-0.25*10 -7 / N.m, when the maximum value appears at 200℃, only 0.45*10 -7 / N.m, fully up to national standards. After exten...

Embodiment 2

[0028] Ceramic fiber 12%, mineral fiber 6%, resin 8%, chalcocite powder 10%, graphite 15%, barium sulfate 10%, biological calcification particles 10%, coke 4%, friction reducing agent 10%, performance adjustment Agent 5%, filler 10%, total 100%.

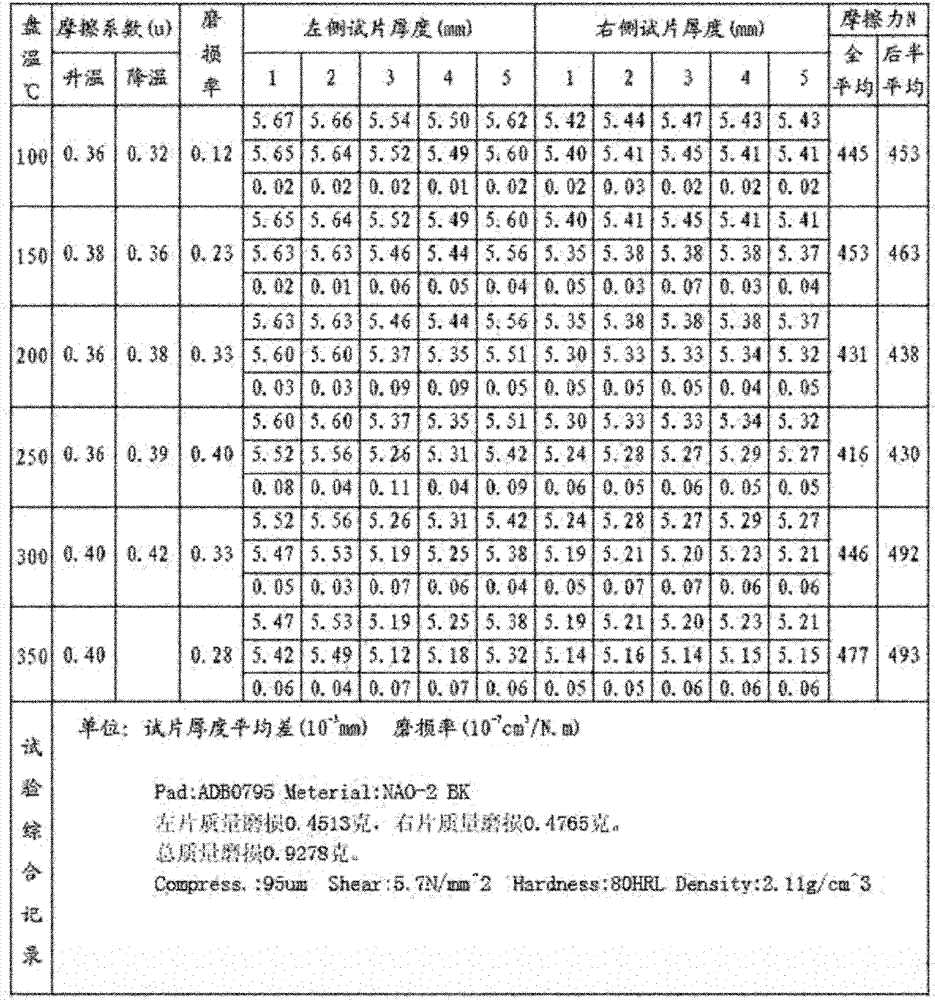

[0029] The above-mentioned materials were made into brake pads according to the conventional pressing method, and they were tested according to 4 types on a constant speed testing machine according to the GB5763-2008 standard. The results are shown in Table 2.

[0030] Table 2:

[0031]

[0032] It can be seen from the data in Table 2 that the friction material obtained in Example 2 of the present invention has a friction coefficient of 0.36-0.40 in the heating stage, and a friction coefficient of 0.32-0.42 in the cooling stage, and has a low wear rate, which fully meets the national standard. After extensive use in the taxis of Santana, Sonata and Jetta, the braking is stable, the braking noise is small, and the friction material life rea...

Embodiment 3

[0034] Ceramic fiber 8%, mineral fiber 7%, resin 6%, chalcocite powder 8%, graphite 12%, barium sulfate 10%, biological calcification particles 15%, coke 3%, friction reducing agent 13%, performance adjustment Agent 8%, filler 10%, total 100%.

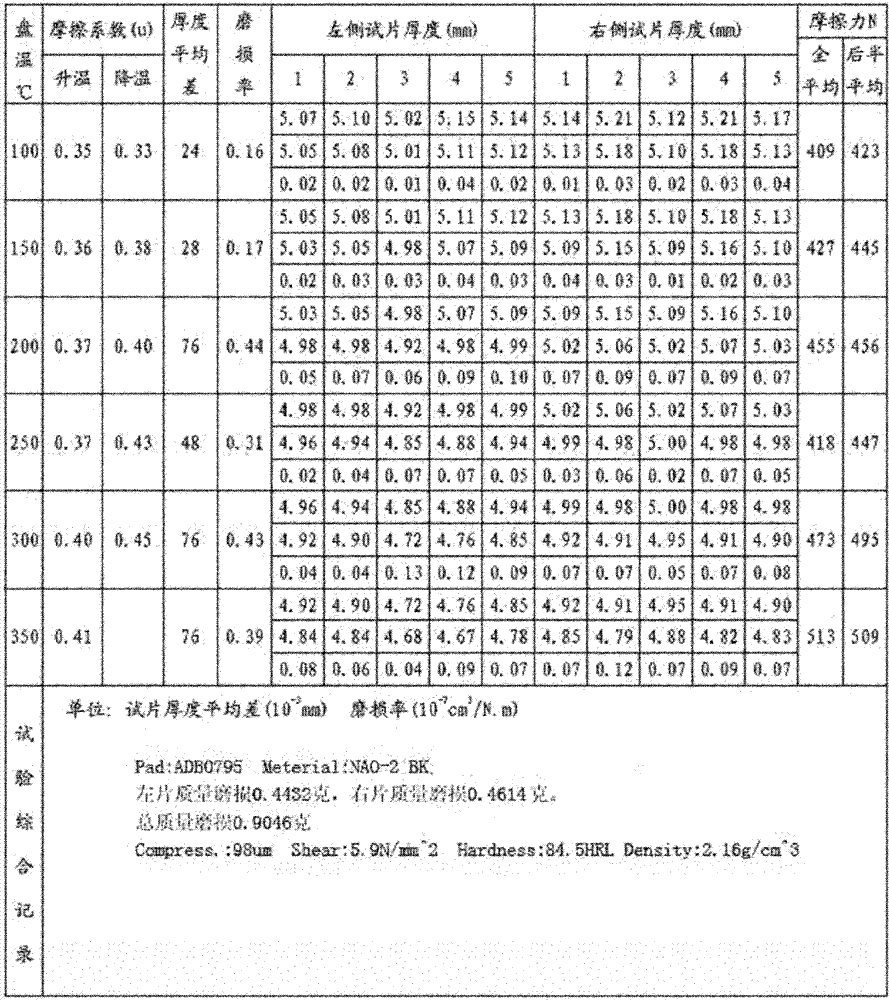

[0035] The above-mentioned materials were made into brake pads according to the conventional pressing method, and they were tested in 4 categories on a constant-speed testing machine according to the GB5763-2008 standard. The results are shown in Table 3.

[0036] table 3:

[0037]

[0038] It can be seen from the data in Table 3 that the friction material obtained in Example 3 of the present invention has a friction coefficient of 0.35-0.41 during the heating stage, and a friction coefficient of 0.33-0.45 during the cooling stage, and has a low wear rate, which fully meets the national standard. After extensive use in the taxis of Santana, Sonata and Jetta, the braking is stable, the braking noise is small, and the friction material life re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com