Preparation method of halogen-free flame-retardant and high-toughness modified polycarbonate (PC)

A polycarbonate, high-toughness technology, used in the preparation of modified polycarbonate, can solve the problems of low mechanical strength and impact strength, fragile products, etc., achieve good color, improve flame retardant effect, good flame retardant and The effect of impact strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

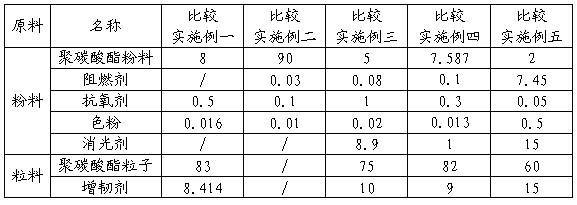

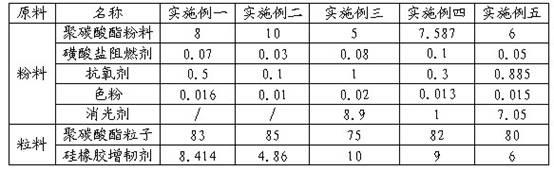

[0033]Powdered raw materials: 8 parts of polycarbonate powder, 0.07 part of potassium benzenesulfonylbenzenesulfonate (KSS) flame retardant, 0.5 part of antioxidant 1010, and 0.016 part of toner.

[0034] Granular raw materials: 83 parts of polycarbonate particles, 8.414 parts of high-temperature vulcanized silicone toughening agent.

[0035] Preparation: Mix the above weight parts of powder in a high-speed mixer, and then send them into the powder feeding hopper; mix the above weight parts of granules in a particle mixer, and then send them into the particle hopper; then use a computer to control according to the formula ratio Feeding ratio and feeding amount, after the heating part of the twin-screw extruder reaches the extrusion temperature of 270°C, control the feeding according to the set feeding ratio, and the twin-screw extruder will melt, mix and extrude the above raw materials; Finally, the extruded material is cooled and pelletized, weighed and packaged to obtain gra...

Embodiment 2

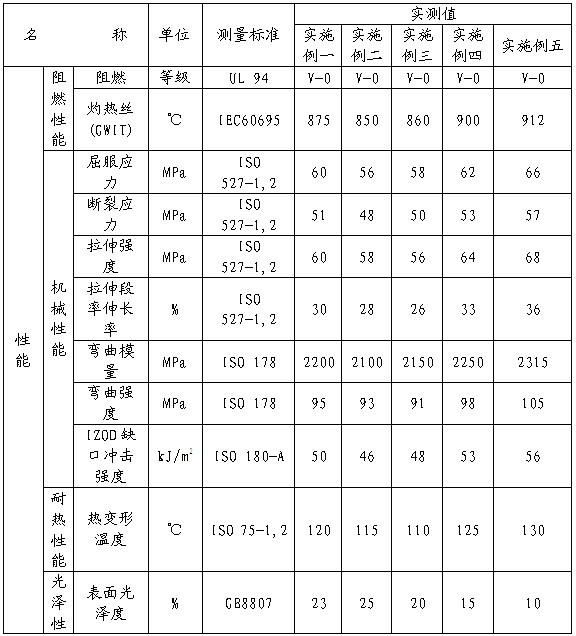

[0038] The preparation method is the same as in Example 1. The difference is the selection and proportioning of powder and pellets. The flame retardant is 2,4,5-trichlorobenzenesulfonate sodium (STB), and the antioxidant is antioxidant 168. The specific ratio is shown in Table 1, and the test results are shown in Table 3.

Embodiment 3

[0040] The preparation method is the same as in Example 2. The difference is the ratio of powder and pellets and the powder contains cross-linked butadiene rubber powder matting agent, the specific ratio is shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| gloss | aaaaa | aaaaa |

| gloss | aaaaa | aaaaa |

| gloss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com