Mixed flow turbocharger with variable nozzle ring

A turbocharger and nozzle ring technology, applied in the direction of machines/engines, stators, engine components, etc., to solve the problem of high-temperature gas sealing, good matching effect, and reduce the effect of air flow loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

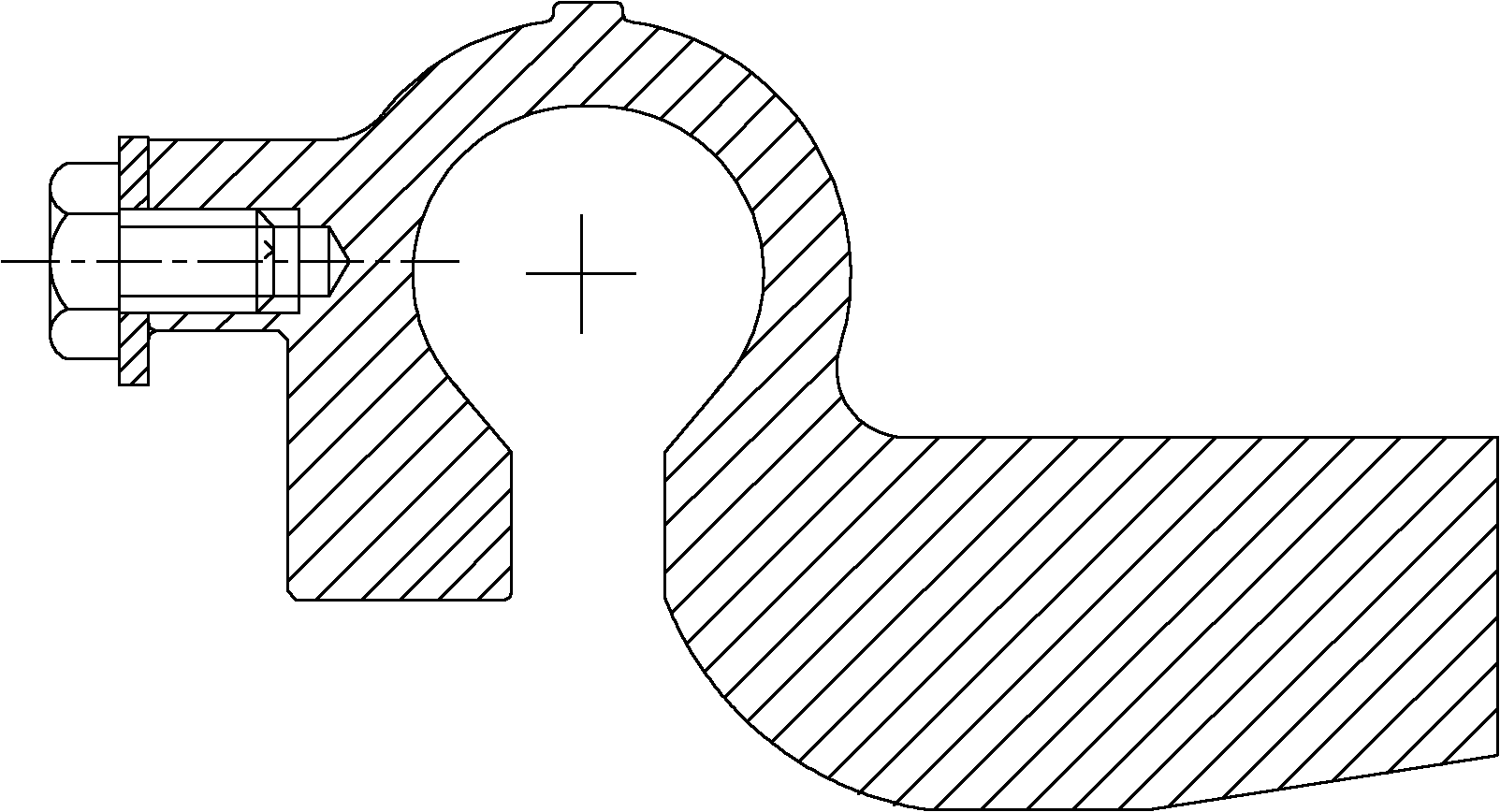

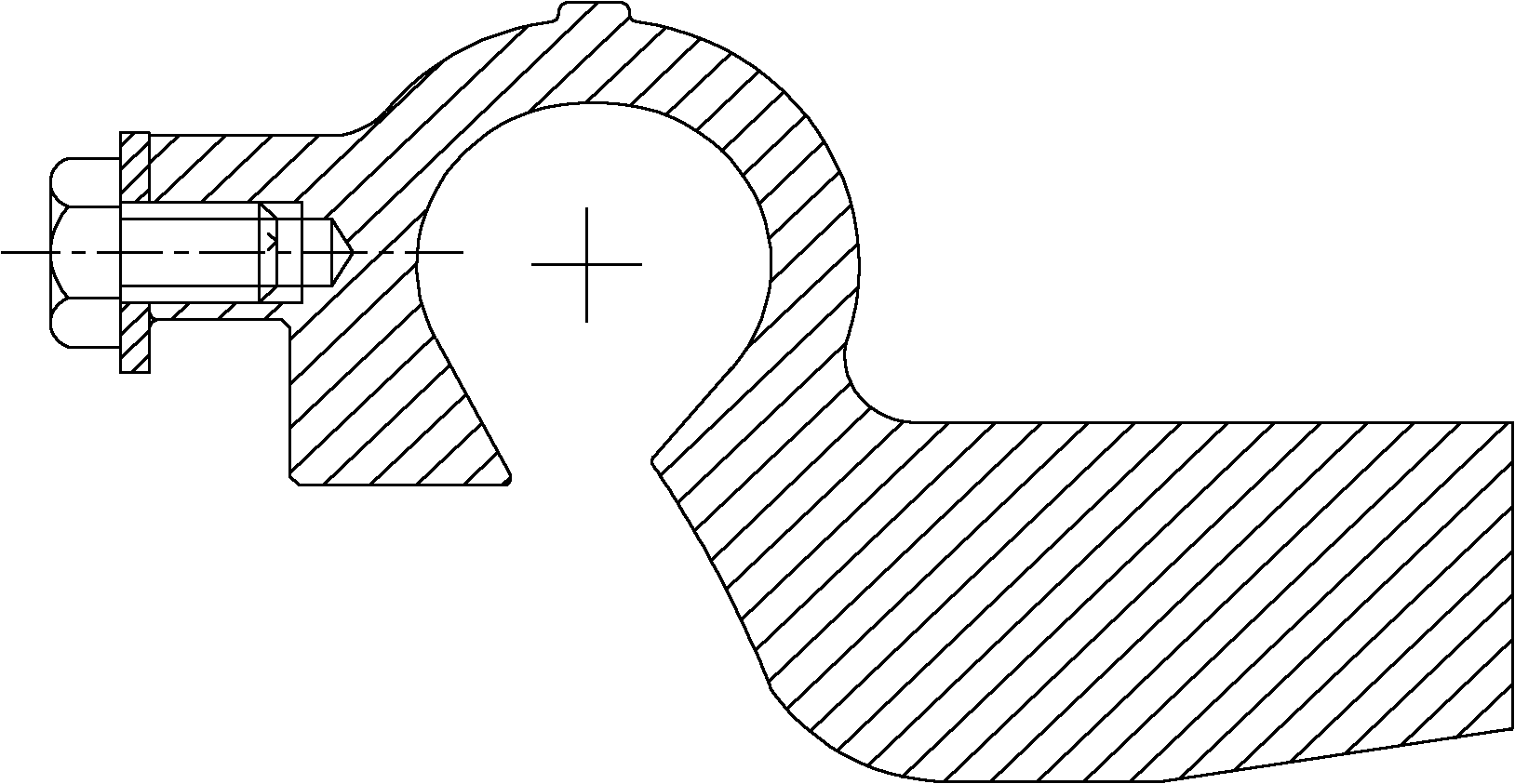

[0044] The following is attached Figure 5 , 6 , 7, explain the specific implementation of the mixed-flow turbocharger with nozzle ring involved in the present invention: when the working condition of the engine changes, the pneumatic actuator or electric actuator 3 acts on the rocker arm assembly 4 fixed at the turbine end Rotating, the rocker arm assembly 4 moves the active rocker arm 1 through the fork to drive the drive ring 2 inside the supercharger to rotate around the turbine shaft 10 . The driving ring applies a torque to the space mechanism 8, and under the joint action of the rotary pair 15 and the ball pair 14, the nozzle ring blades 5 rotate around their rotating shafts. The torsion angle of the nozzle ring blade 5 has a certain internal relationship with the rotation range of the rocker arm assembly 4, and can be adjusted and controlled in real time according to the opening of the nozzle ring to be satisfied, that is, the pressure of the external air source can b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com