Hydraulic control system for gear shifting of manual gearbox

A technology of a hydraulic control system and a manual gearbox, applied in the field of vehicle parts, can solve the problems of increasing the complexity of the control transmission mechanism, difficulty in remote manual operation, and driver fatigue, so as to reduce labor intensity and overcome long-distance manual operation. , Simplify the effect of operating the transmission mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

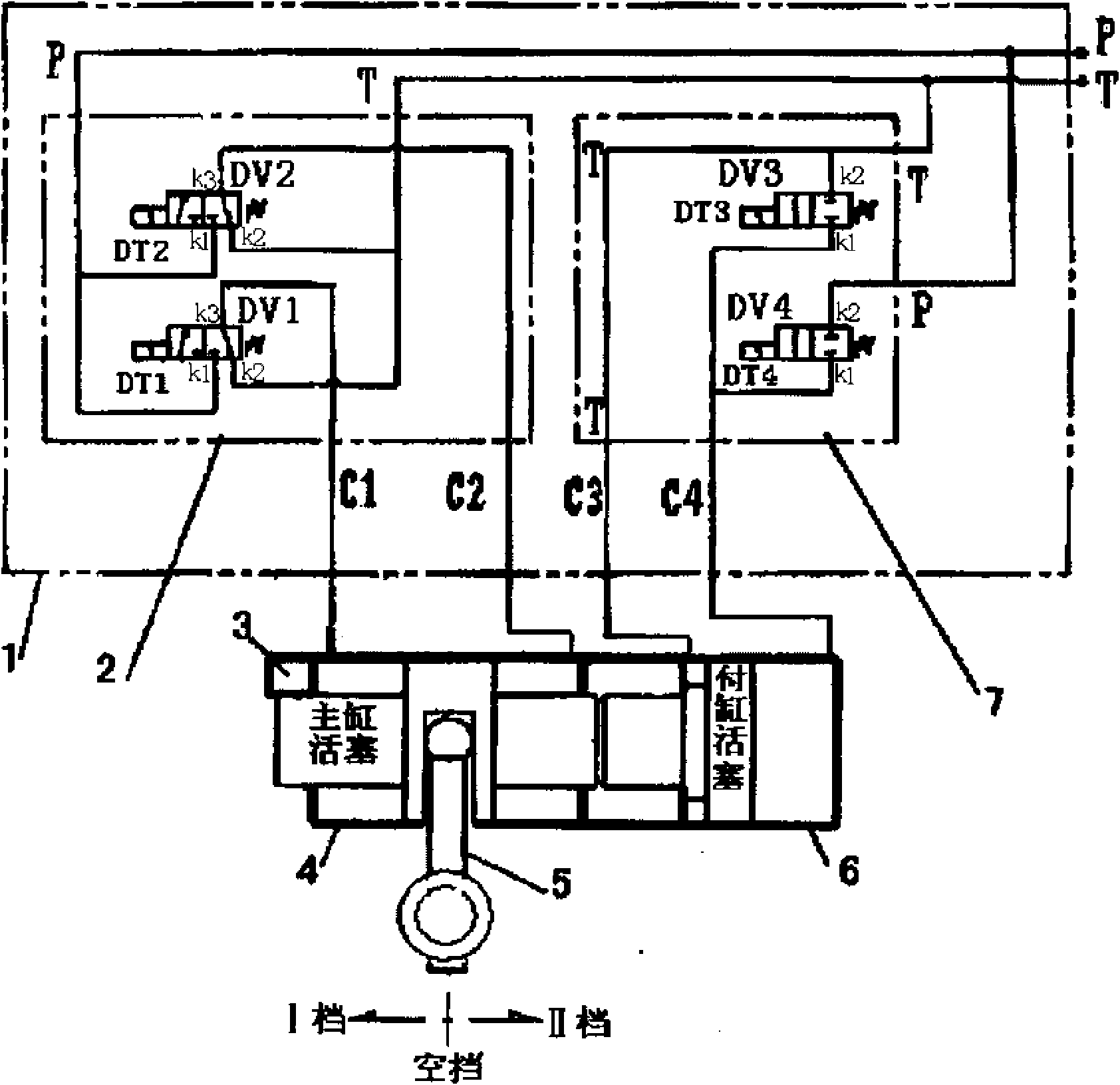

[0018] The invention proposes a hydraulic control system for gear shifting of a manual transmission. Be described below in conjunction with accompanying drawing.

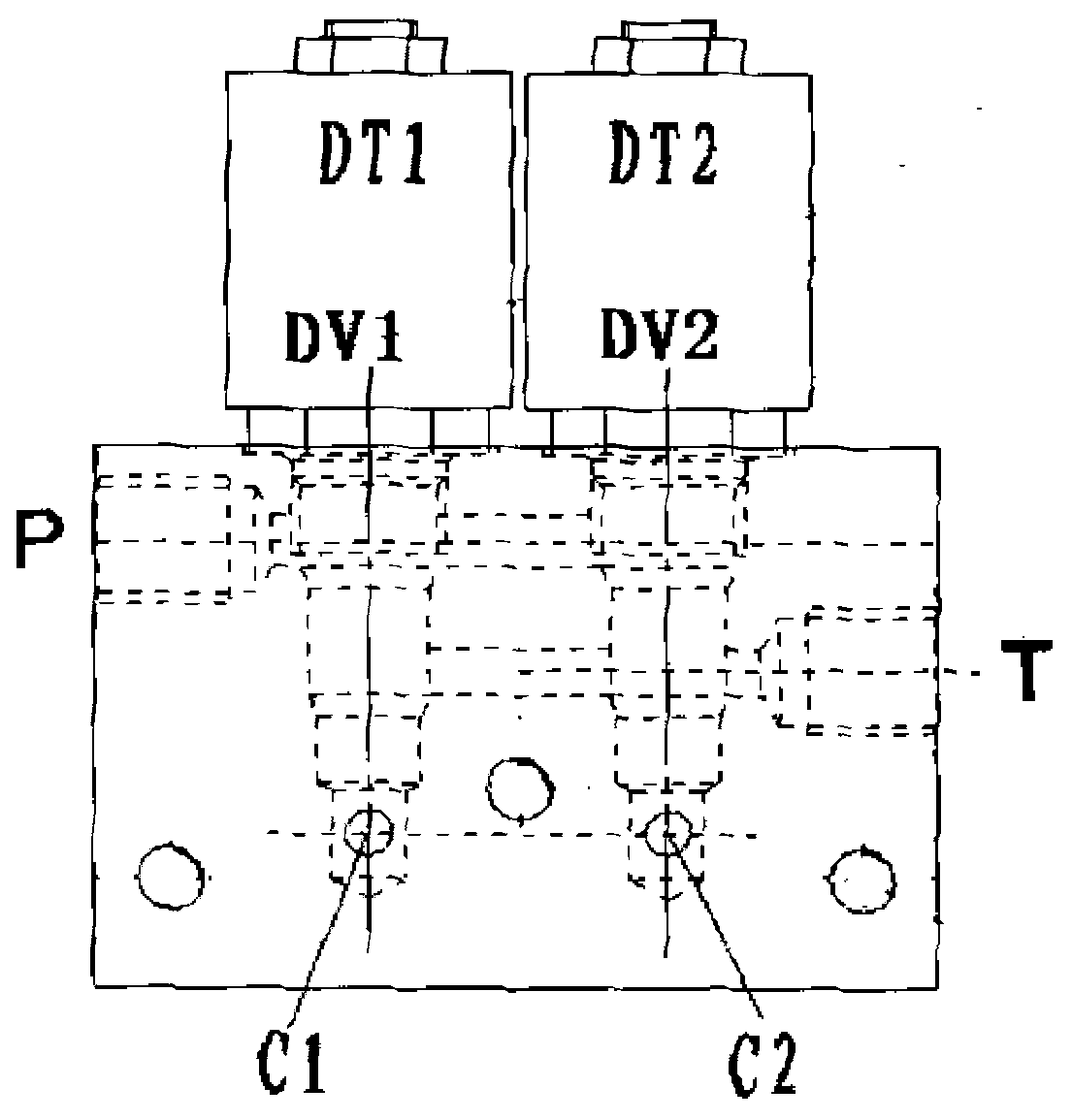

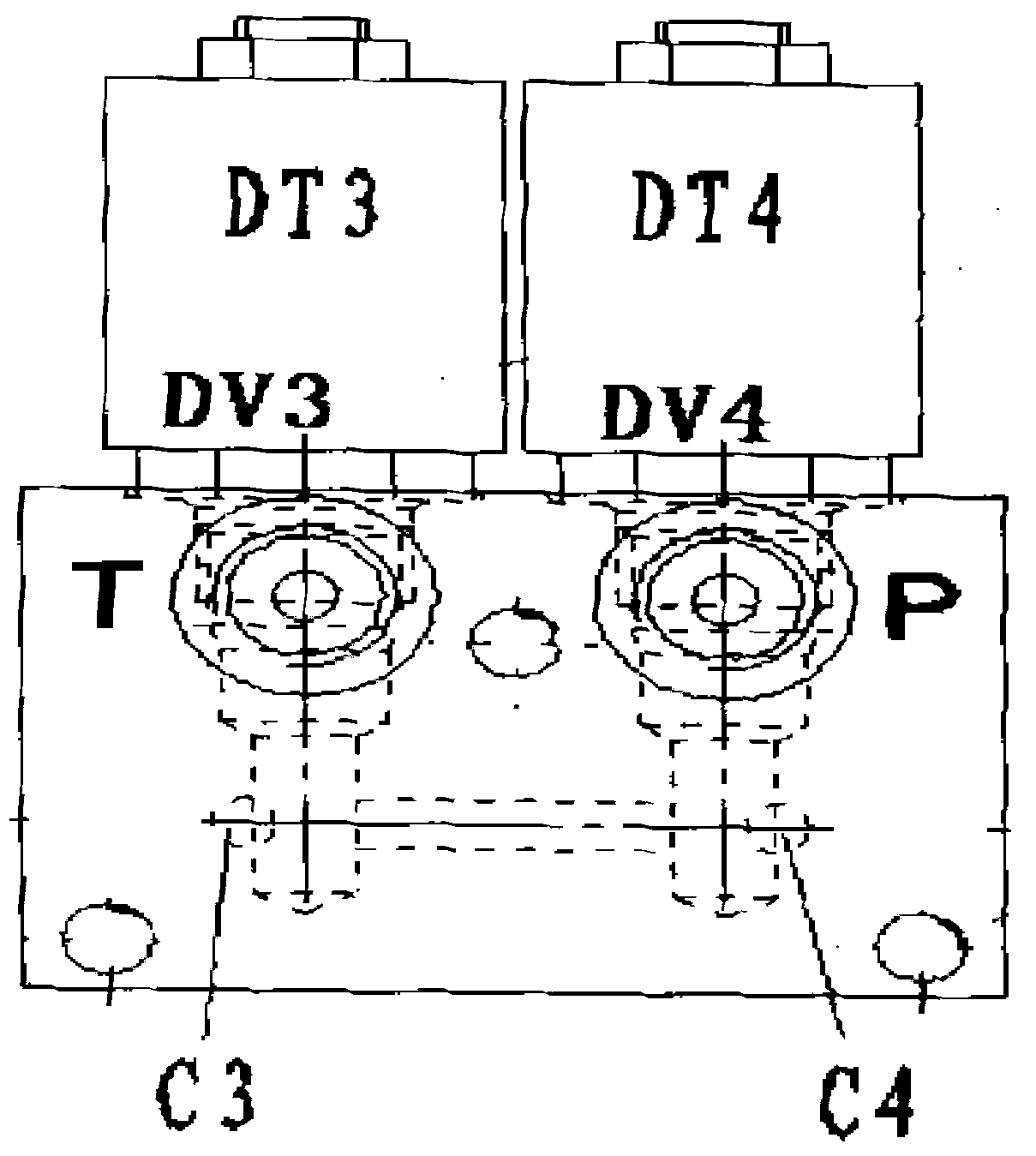

[0019] figure 1 Shown is a schematic structural diagram of the hydraulic control system for manual transmission shifting. The hydraulic control system for shifting gears of the manual transmission in the figure is composed of two parts, the shift cylinder and the control valve group 1 . The shift cylinder is composed of a master cylinder, an auxiliary cylinder, a position sensor and a shift lever integrated as a whole; the position sensor 3 is installed on the side of the master cylinder 4 of the shift cylinder, and is driven by the piston in the master cylinder, and the shift lever 5 Installed at the piston of the master cylinder 4; the master cylinder valve block 2 in the control valve group 1 is composed of the first three-way screw-in solenoid valve DV1 and the second three-way screw-in solenoid valve installe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com