On-line detection method of wheel steel billet angular deviation and detection system thereof

A detection system and detection method technology, applied in the detection field, can solve the problems of no wheels, heavy workload, easy missed inspection, etc., and achieve the goal of improving yield and product quality, reducing material waste and work waste, and reducing manual inspection costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

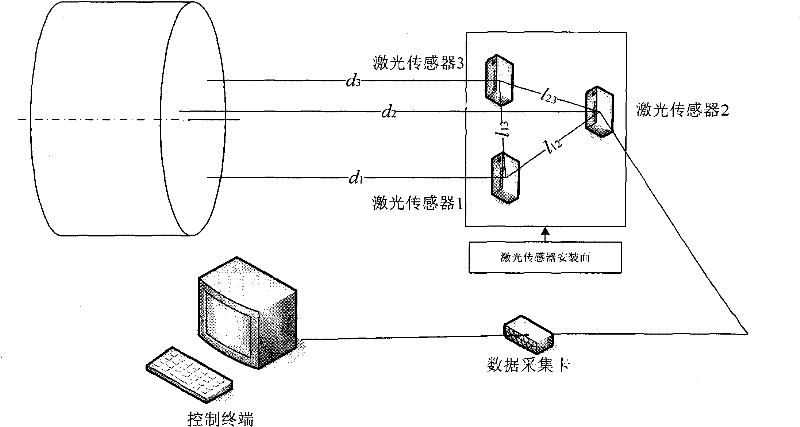

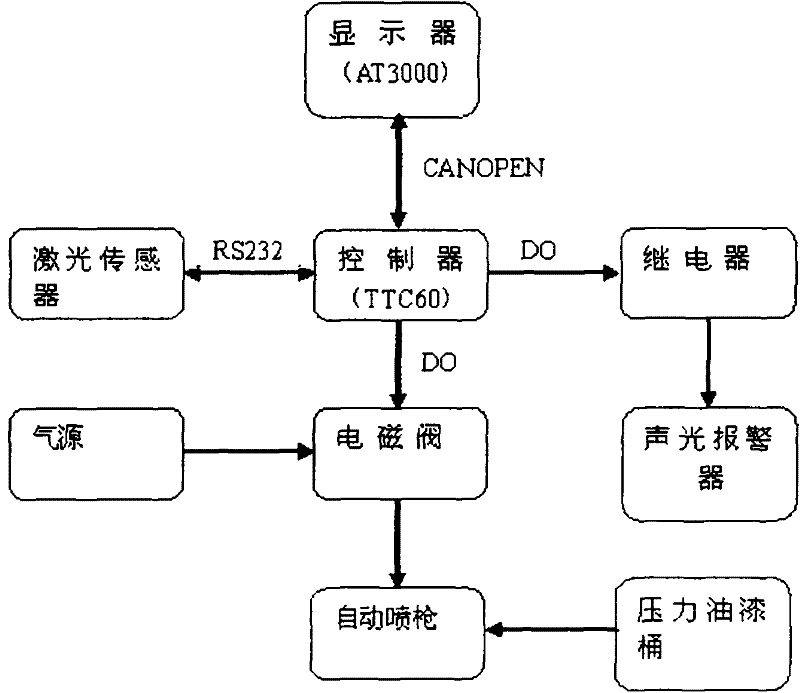

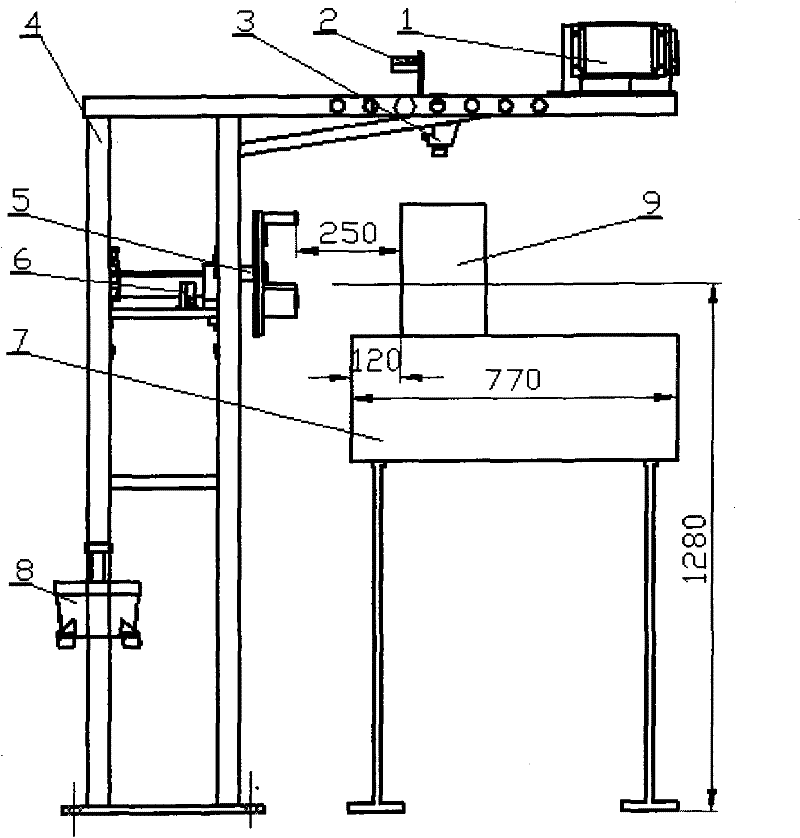

[0039] A detection system for detecting angular deviation of a wheel billet with an outer diameter of φ380mm or φ450mm ( figure 2 , image 3), consisting of a hardware part and a software part, the hardware part consists of a control cabinet assembly (1), a gas-liquid electromagnetic reversing valve (2), an automatic spray gun (3), a frame (4), and a laser distance measuring sensor assembly (5) , a pneumatic electromagnetic reversing valve (6), a paint pressure mixing tank (8), a four-way joint and pipelines; the software part is composed of a signal communication module, a drive control module, a data acquisition and processing module, and an alarm module.

[0040] Such as image 3 As shown, the laser ranging sensor assembly (5) is facing the steel billet (9) with a distance of 250mm, and the automatic spray gun (3) is installed on the frame (4) directly above the steel billet with a distance of 150mm. Such as Figure 4 As shown, the used sensor of this system is an ultra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com