Flicker-wavelength-shifting optical fiber and fast neutron conversion screen

A technology for converting screens and optical fibers, applied in cladding fibers, optical waveguides and light guides, and measuring with scintillation detectors, etc. Improve the efficiency and resolution of fast neutron detection, achieve commercial mass production, and mature the generation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings.

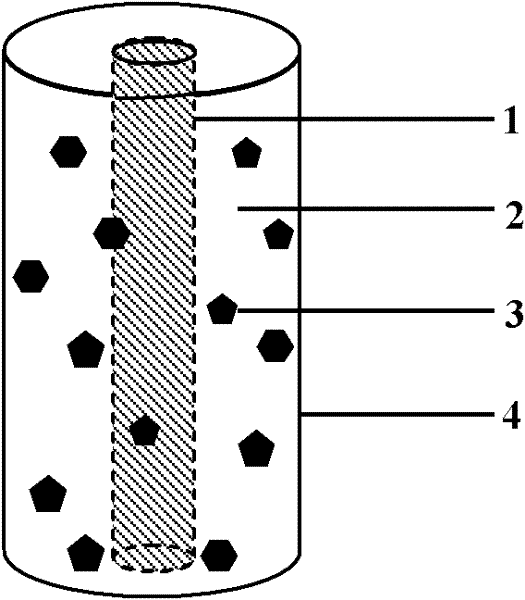

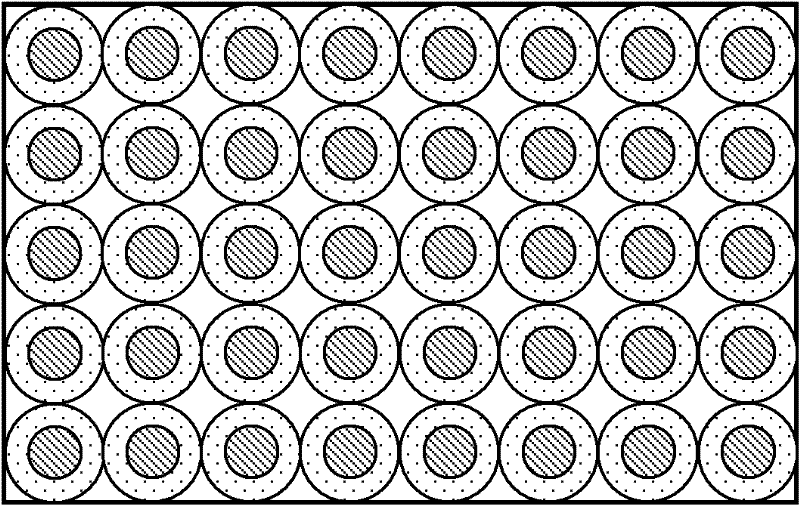

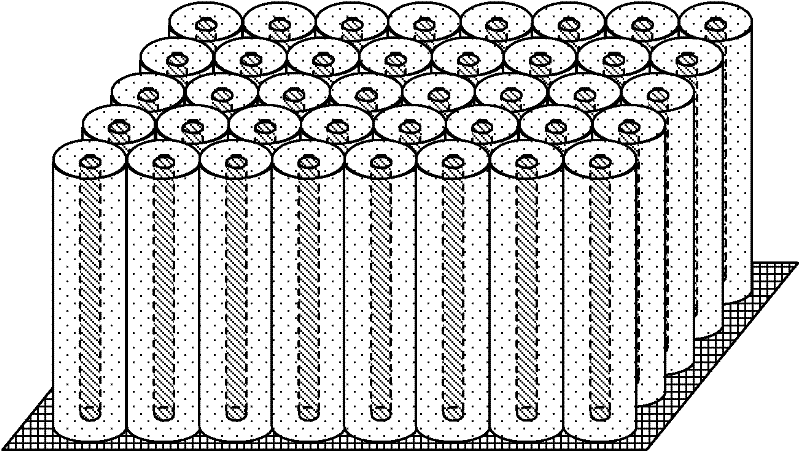

[0029] figure 1 It is a scintillation-wave-shifting optical fiber for fast neutron detection. The core layer 1 is a wave-shifting (fluorescent) optical fiber, the cladding layer is a high hydrogen-containing organic substance 2 doped with phosphor powder 3 , and the outermost layer is a reflective film 4 . According to the resolution requirements, the diameter of the wave-shifting (fluorescent) fiber in the core layer 1 is 1 / 4 to 3 / 4 of the total diameter of the flicker-wave-shifting fiber, generally 0.25 to 1 mm; The mass ratio of the phosphor powder 3 ranges from 1:1 to 9:1, or the mass doping ratio of the phosphor powder is 10% to 50%, generally 1:1; the coated outer reflective film 4 can be an aluminum film.

[0030] Fast neutron detection with scintillation - the diameter of the wave-shifting fiber determines the resolution of the fast neutron conversio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com