Bread rich in soybean cellulose and preparation method thereof

A technology of soybean cellulose and a production method, which is applied in the directions of dough processing, baking, and baked food, can solve the problems of inconvenient nutrient absorption, unfavorable nutrient dissolution, poor particle quality of soybean flour, etc., so as to improve product added value, Improve gastrointestinal digestive function, the effect of simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

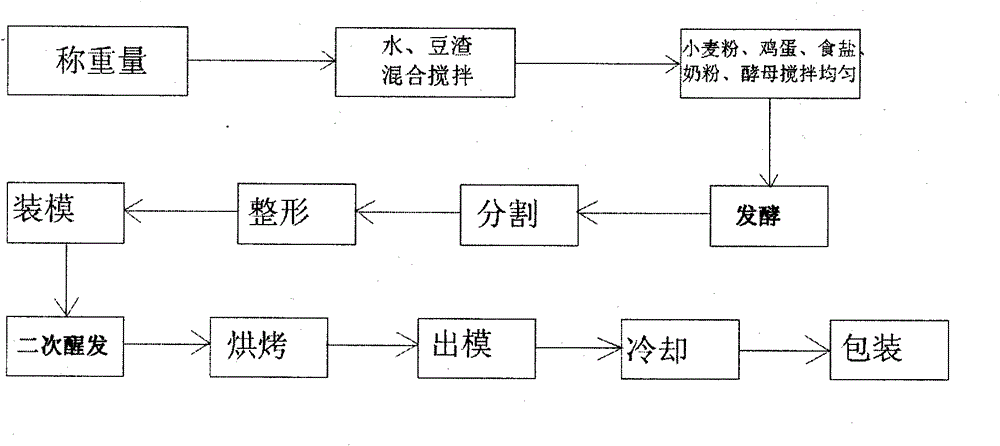

Image

Examples

Embodiment 1

[0025] A method for making bread rich in soybean cellulose, the method is as follows: 20kg of wheat flour, 8kg of bean curd residue, 8kg of water, 4kg of eggs, 3kg of milk powder, 1kg of edible oil, 1kg of white sugar, 0.3kg of salt and 0.15kg of yeast powder;

[0026] (1) First put the water in the mixing container, then put in the bean curd residue, and mix for 2 minutes at 60 rpm;

[0027] (2) Then add wheat flour, milk powder, eggs, salt, edible oil, sugar and yeast powder into the mixing container in turn, mix and stir at 60 rpm for 2 minutes, then stir at 100 rpm, and add yeast at the same time Stir the powder for 4 minutes, and finally knead at 150 rpm for 6 minutes to show the gluten state;

[0028] (3) Put the uniformly stirred mixture at a temperature of 15° C. for fermentation and cultivation for 3 hours;

[0029] (4) Divide the dough after fermentation, weigh 120 grams, shape and mold;

[0030] (5) Place the molded dough at a temperature of 18°C for a second pr...

Embodiment 2

[0034] A method for making bread rich in soybean cellulose, the method is as follows:

[0035] Its formula is as follows according to weight ratio: 25kg of wheat flour, 10kg of bean curd dregs, 10kg of water, 4.21kg of eggs, 3.25kg of milk powder, 1.4kg of edible oil, 2kg of white sugar, 0.5kg of salt and 0.2kg of yeast powder;

[0036] (1) First put the water in the stirring container, then put in the bean curd residue, and mix for 3 minutes at 80 rpm;

[0037] (2) Then add wheat flour, milk powder, eggs, salt, edible oil, sugar and yeast powder into the mixing container in turn, mix and stir at 80 rpm for 4 minutes, then stir at 120 rpm, and add yeast at the same time Stir the flour for 6 minutes, and finally knead at 160 rpm for 8 minutes to show the gluten state;

[0038] (3) Put the uniformly stirred mixture at a temperature of 35°C for fermentation and cultivation for 2 hours;

[0039] (4) Divide the dough after fermentation, weigh 400 grams, shape and mold;

[0040] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com