Biotype femoral head surface substitutive prosthesis

A femoral head, bio-based technology, applied in the direction of femoral head, prosthesis, joint implants, etc., can solve the problems of short prosthesis life, large resection surface, unequal walking, to avoid bone cement loosening, prosthesis life Long, strong bond effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

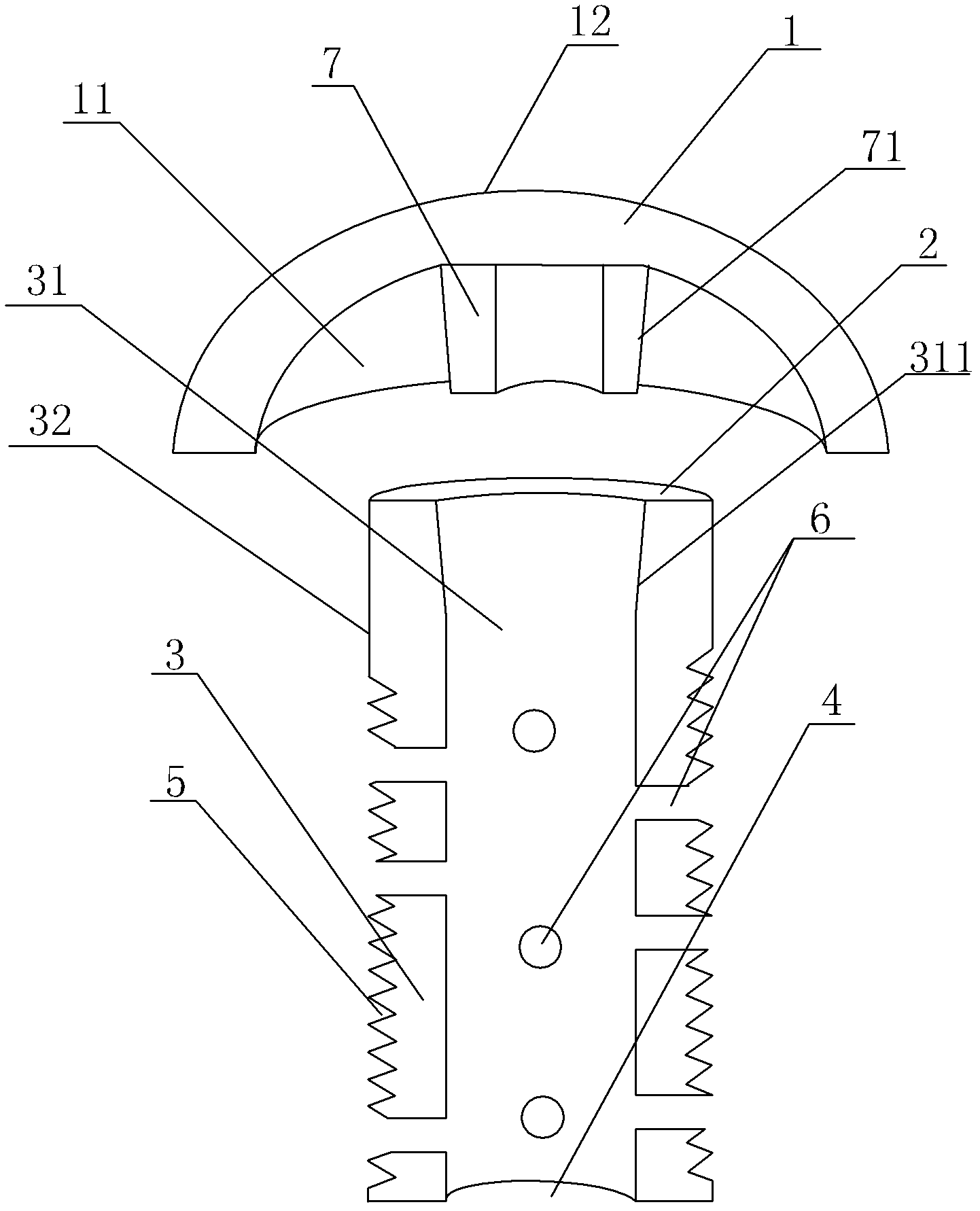

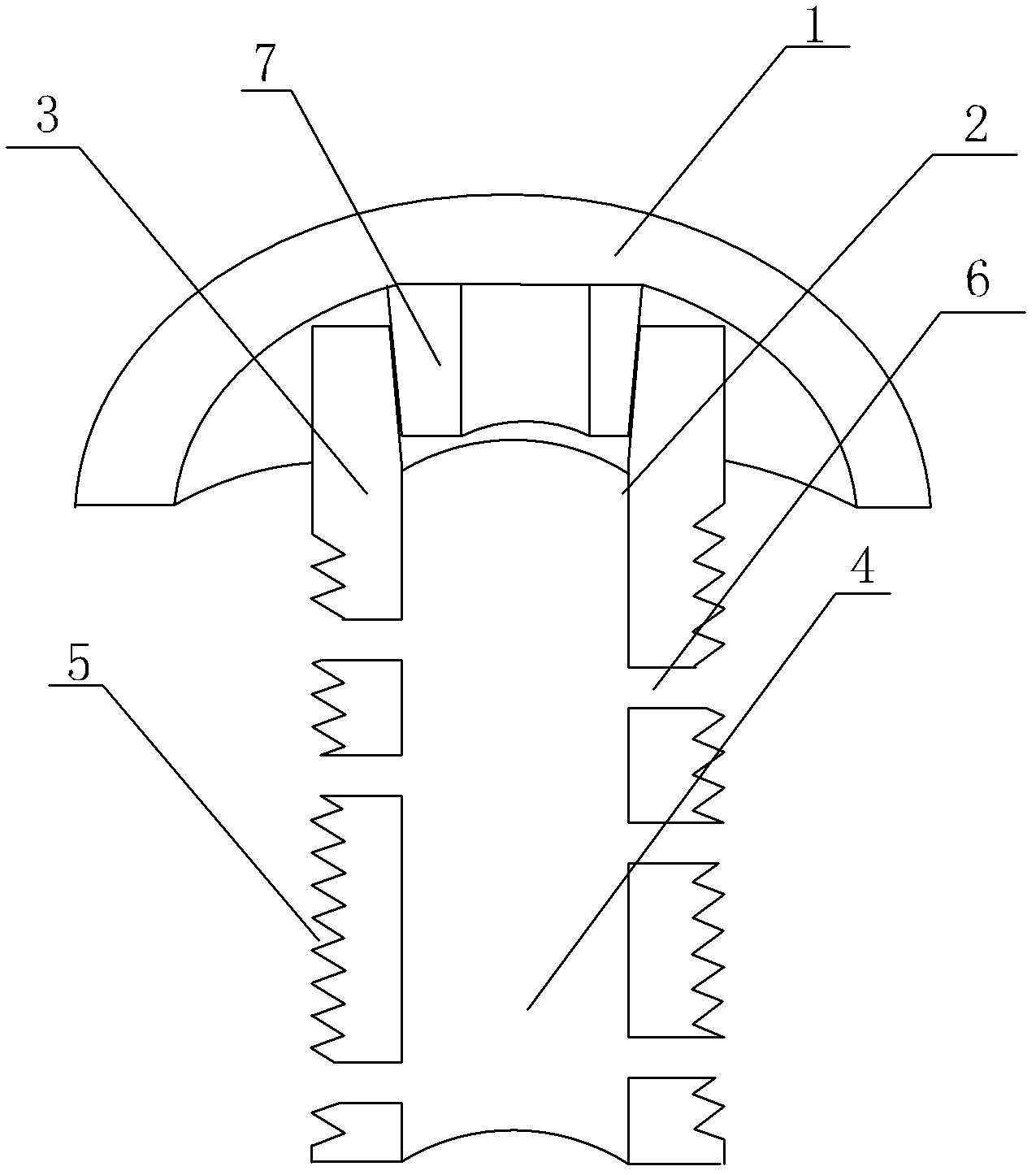

[0018] Such as figure 1 and figure 2 A biotype femoral head surface replacement prosthesis shown includes a single cup 1 and a central rod. The central rod is a hollow hollow tube 2 composed of a lumen 4 and a tube wall 3. The thickness of the tube wall 3 is 0.6 cm. The diameter of the cavity 4 is 1.3 cm, the tube wall 3 is provided with an external thread 5, and the tube wall 3 is provided with 10-18 growth through holes 6 communicating with the tube cavity 4, and the diameter of the growth through holes 6 is 0.3-0.5 mm , the single cup 1 is provided with an intubation tube 7 inserted into the lumen 4, the outer surface 71 of the intubation tube 7 is an inclined plane, the angle between the inclined plane and the vertical line is 20 degrees, and the inner wall 3 of the hollow tube 2 The surface 31 is provided with an inclined surface 311 matching the outer surface 71 of the cannula 7, and the angle between the inclined surface 311 and the vertical line is also 20 degrees, a...

Embodiment 2

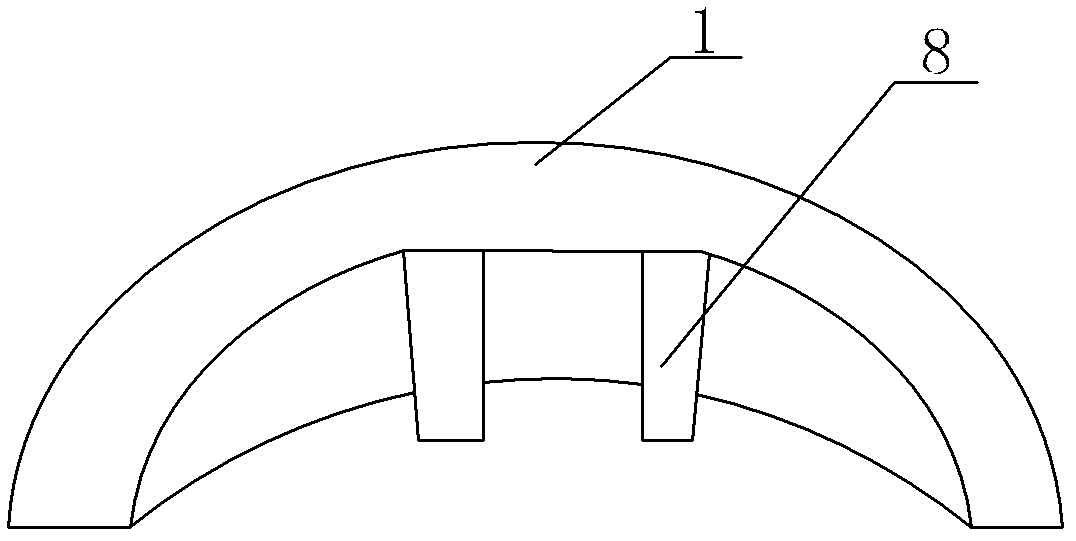

[0020] Basically the same as the embodiment, the only difference is as figure 2 The upper intubation tube 7 of the shown single cup 1 is replaced by a pair of tongue inserts 8, the thickness of the tube wall 3 is 0.5 cm, and the diameter of the lumen 4 is 1.0 cm.

Embodiment 3

[0022] It is basically the same as the embodiment, except that the thickness of the tube wall 3 is 1.0 cm, and the diameter of the lumen 4 is 1.5 cm.

[0023] In the above-mentioned embodiment, 10, 12, 15 or 18 through-holes can be set up. Under the load-bearing condition of the hollow tube, it is better to have more through-holes for growth, which is beneficial to the level of bone fusion inside and outside the hollow tube. To prevent the hollow tube from having insufficient load-bearing capacity when it is not fully fused with the femur, we selected a range of 10-18 after biomechanical verification; its diameter can be 0.3, 0.4, or 0.5 mm, etc. Set the size of the growth through hole under the condition that the tube load allows.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap