Granulated powder and method for producing granulated powder

A manufacturing method and powder technology, which can be used in the granulation of special binders, metal processing equipment, thin material processing, etc., and can solve the problems of granulation powder filling and inability to obtain products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1A

[0166] First, as a raw material powder, stainless steel powder with an average particle diameter of 6 μm (manufactured by EPSON ATMIX Co., Ltd., SUS-316L, true density 7.98 g / cm 3 ) produced by a water atomization method was prepared.

[0167] On the other hand, polyvinyl alcohol (manufactured by Kuraray Co., Ltd., RS-1717) was prepared as an organic binder. And, ion-exchanged water was prepared as a solvent. In addition, the added amount of the solvent was 50 g per 1 g of the organic binder.

[0168] Next, polyvinyl alcohol was mixed into ion-exchanged water and cooled to room temperature to prepare an organic binder solution. Moreover, the addition amount of polyvinyl alcohol was the quantity of 0.8 weight part with respect to 100 weight part of metal powders. In addition, the degree of saponification of polyvinyl alcohol was 93, and the degree of polymerization was 1700.

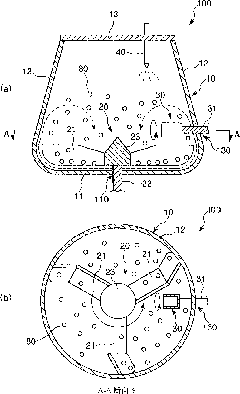

[0169] Next, the raw material powder was charged into the processing vessel of a tumbling granul...

Embodiment 2A~8A

[0178] A granulated powder was obtained in the same manner as in Example 1A, except that the addition amount of the organic binder or the low water-soluble material and its addition amount were changed to those in Table 1.

Embodiment 9A

[0180] Before making secondary particles, the raw material powder is sprayed with a solution of low water-soluble material and allowed to dry. In this way, the inner coating layer covering the surface of the raw material powder was formed. Thereafter, using the raw material powder on which the inner coating layer was formed, a granulated powder was obtained in the same manner as in Example 1A.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com