ECAE (equal channel angular extrusion) based preparation method of ultrafine crystal NiTi shape memory alloy tube

A technology of equal-diameter angular extrusion and memory alloy, which is applied in the field of ultra-fine-grained nickel-titanium shape memory alloy pipes prepared by radial-angle extrusion technology, can solve the problem of difficult to accurately determine the position, uneven structure of the tube blank, and difficult to uniform structure and other problems, to achieve the effect of reducing deformation resistance, large deformation, and uniform organization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

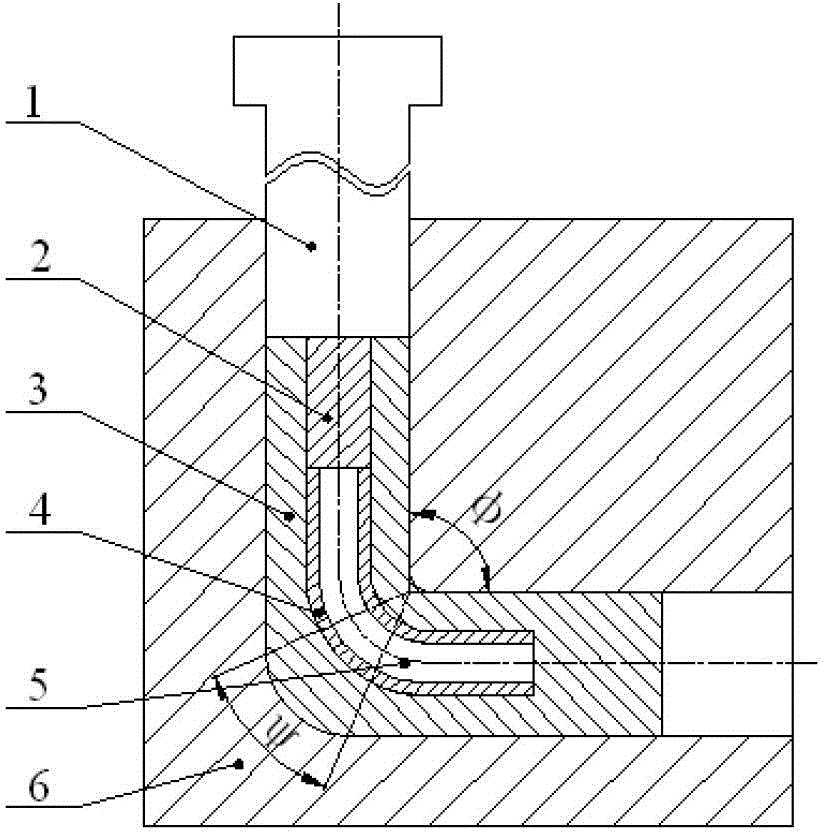

[0019] The present invention is described in more detail below in conjunction with accompanying drawing example:

[0020] combine figure 1 , the basic principle of the present invention's method of wrapping and preparing ultra-fine-grained nickel-titanium shape memory alloy pipes based on equal diameter angular extrusion technology is: insert a metal core 5 into the inside of the nickel-titanium shape memory alloy tube blank 4 to be formed, and then Enclose it in the metal sleeve 3, and use ECAE tooling (composed of the punch 1 and the die 6) to simultaneously perform large shear plastic deformation on the metal sleeve 3 and the metal tube blank 4 and filler metal 5 inside the metal sleeve 3 to realize nickel-titanium Grain refinement of shape memory alloy tube stock. Since the metal core inside the metal tube blank and the outer cladding metal are made of high-plasticity and low-strength metal materials, compared with the hard-to-deform bulk nickel-titanium shape memory allo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com