Cold drawing method and die for special-shaped pipes

A special-shaped tube and cold-drawing technology, applied in wire drawing dies, metal processing and other directions, can solve the problems of difficult cold-drawing processing of special-shaped tubes, small effective heat exchange area, immature production technology, etc. The effect of stable quality and stable size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

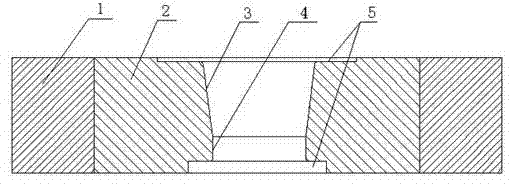

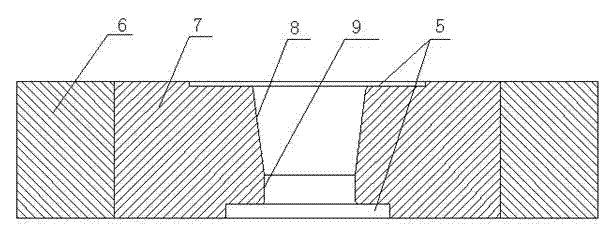

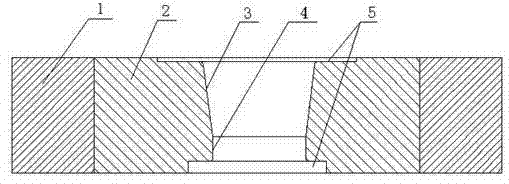

[0029] The specific content of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0030] Such as Figure 1-Figure 2 As shown, a cold drawing method for special-shaped tubes:

[0031] A. Pretreatment, including:

[0032] 1. Heading: cut off the head of one side and the sharp corners of the ends of the two wings of the tube blank that has initially formed an omega shape, so that the two wings of the tube blank transition smoothly to the tube end, and the burrs are ground off;

[0033] 2. Annealing: The annealing process added after the beginning process fully oxidizes the surface of the billet, so that the glass powder attached to the surface of the billet will naturally peel off along with the scale produced by annealing during the pickling process.

[0034] 3. Pickling: Cool the tube blank to room temperature after annealing, soak the lower acid tank with 15%~20% sulfuric acid, soak at a temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com