Method for producing a structured surface contacting printing material

A technology for structuring and printing materials, applied to the device for coating liquid on the surface, special surface, printing, etc., can solve the problems of loss of adsorption, loss of roughness of lining, loss of anti-adsorption effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

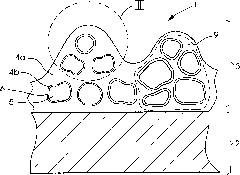

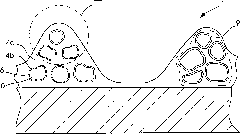

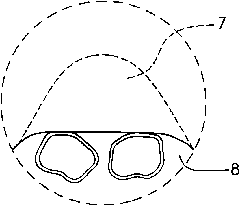

[0030] Figure 1a A schematic sectional view of a preferred embodiment of a drum lining 1 according to the invention is shown. The lining 1 has a base 2 , which is preferably made of stainless steel and alternatively of aluminium, titanium, steel or plastic, and a wear-resistant and corrosion-resistant coating 3 . The coating 3 comprises a sol-gel matrix 4a of crosslinked nanoparticles, with microparticles 5 embedded in the matrix 4a.

[0031] Such sol-gel matrices can be produced or constructed in a conventional manner, preferably according to the matrices disclosed in DE 19957325 A1. Preference is given to using the product "H5055" from FEW Chemie GmbH, Bitterfeld-Wolfen, for the nanosols. However, during the production according to the invention, the particles 5 or the corresponding raw materials of the particles 5 can additionally be dispersed in contrast to known methods. In contrast to known layers, the layer produced according to the invention has the particles embedd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com