RO dense water standard discharge technology in reclaimed water reuse

A concentrated water and reclaimed water technology, applied in water/sewage treatment, adsorption water/sewage treatment, water/sewage multi-stage treatment, etc., can solve reverse osmosis membrane non-fouling clogging, reclaimed water reuse concentrated water can not meet the discharge standard , reverse osmosis can not run for a long time and other problems, to achieve the effect of solving the fouling of reverse osmosis membrane and solving the effect of reverse osmosis not being able to run for a long time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

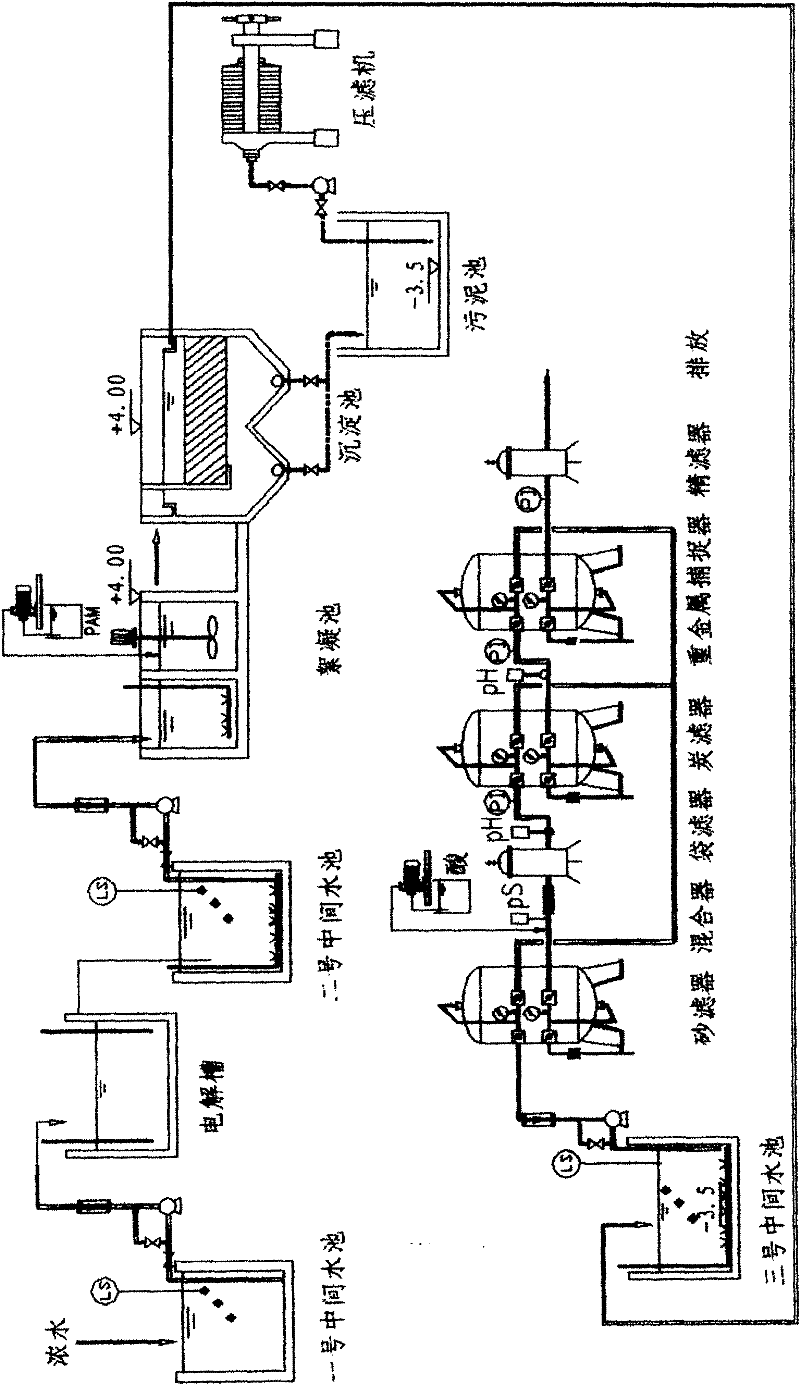

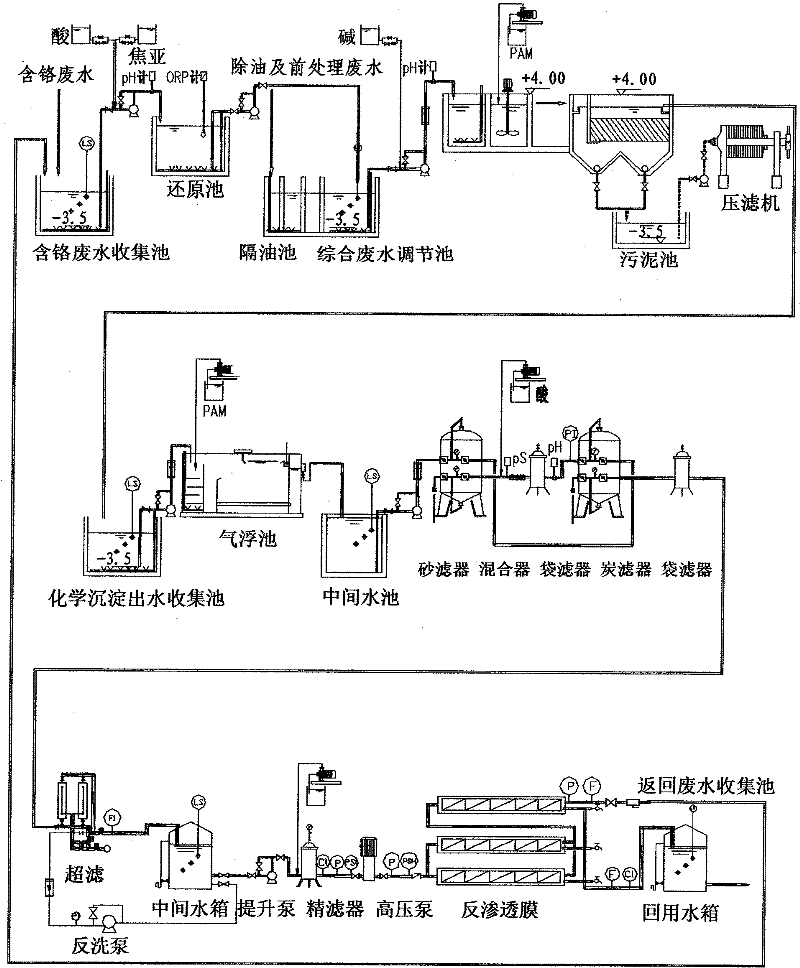

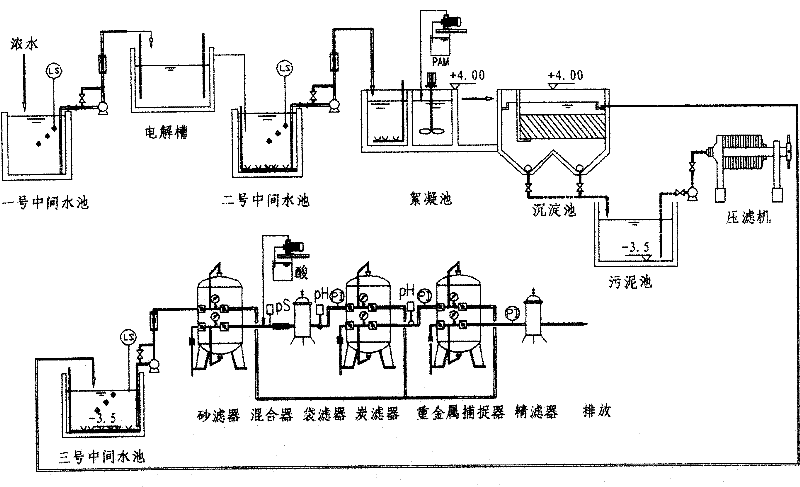

[0020] Such as figure 2 As shown, a process for reusing RO concentrated water up to the standard for reclaimed water includes the following processing steps: a) adding high-concentration concentrated water into the electrolytic cell, and using electrolysis to remove part of the metal ions; b) electrolytically treated Adjust the pH value of the wastewater to 8-9 to make metal ions form hydroxide precipitates, then add flocculant to make hydroxide precipitates form larger alum flower precipitates, the precipitates are collected by pressure filtration, and the precipitated supernatant enters the next treatment Step; c) adding the precipitated supernatant after precipitation treatment to a quartz sand filter for filtration to remove suspended matter and large particles in the water; the quartz sand filter uses quartz sand with a particle size of φ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com