Aqueous transfer glue and preparation method thereof

A transfer glue, water-based technology, applied in adhesive types, non-polymer adhesive additives, adhesive additives, etc., can solve problems such as poor leveling, high latex film-forming temperature, and increased surface tension, and achieve The effect of simple process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

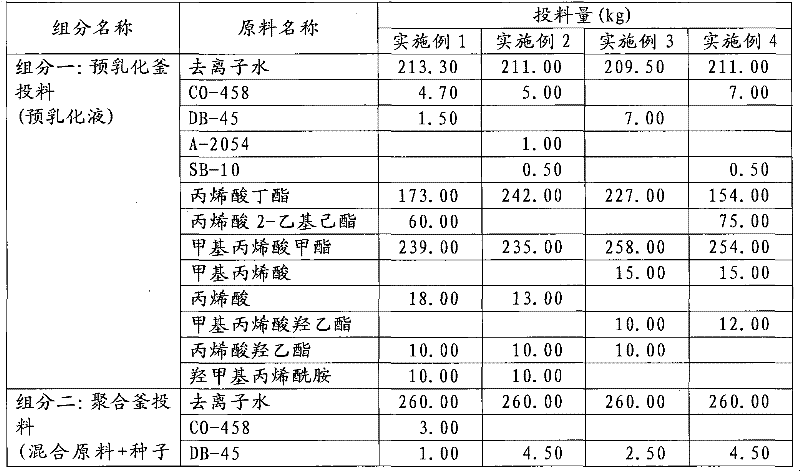

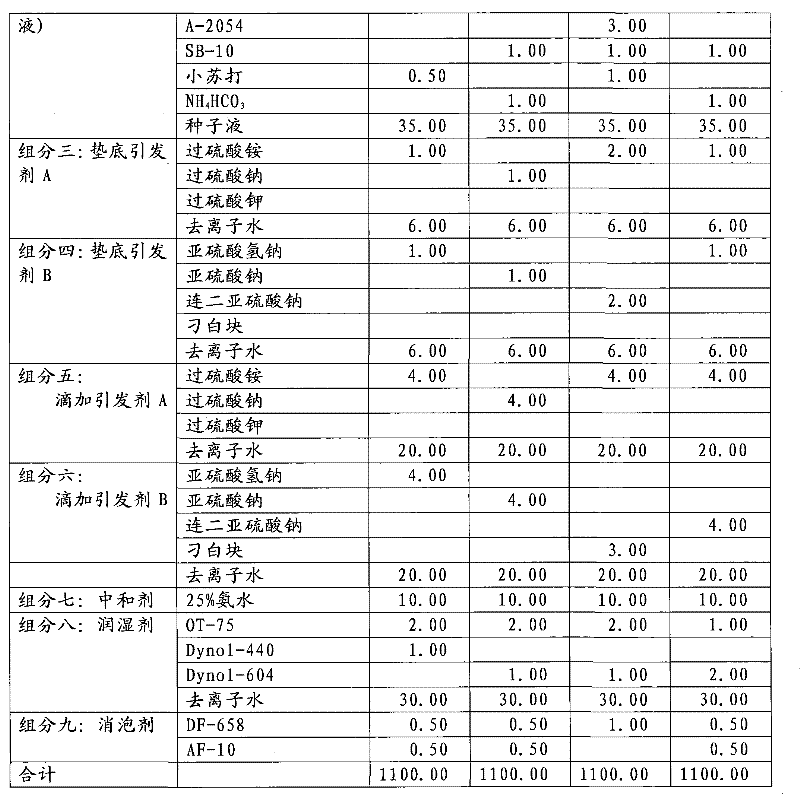

[0036] (a) Add 260.0kg of deionized water, 4kg of emulsifier (ie 3.00kg of CO-458 and 1kg of DB-45) and 0.5kg of buffer (baking soda) into the reactor, stir and heat up to 65~ After 75°C, mixed raw materials are obtained;

[0037] (b) Add 213.30kg of deionized water and 6.2kg of emulsifier (ie 4.70kg of CO-458 and 1.50kg of DB-45) into the pre-emulsification tank, stir for 0 to 20 minutes, then add 18kg of acrylic acid in turn under stirring , 10kg hydroxyethyl acrylate, 239kg methyl methacrylate, 173kg butyl acrylate and 60kg 2-ethylhexyl acrylate, stirred at 20°C for 60 minutes to obtain a pre-emulsion, and 35kg of it was taken out as a seed solution;

[0038] (c) Warm up the mixed raw materials in the polymerization kettle of step a to 60° C., after adding the seed liquid in step b, after stabilizing for 2 to 15 minutes, add the aqueous solution of the persulfate initiator (for the formula, see “Components in Table 1 Three: bottom initiator solution A"), after 5 to 10 minu...

Embodiment 2

[0043] The preparation steps are the same as in Example 1, and the formula and process conditions are shown in Table 1 and Table 2.

Embodiment 3

[0045] The preparation steps are the same as in Example 1, and the formula and process conditions are shown in Table 1 and Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com