Reactive dye pad dyeing and steaming process

A reactive dye and pad dyeing technology, applied in the direction of dyeing method, textile material processing, and textile material processing equipment configuration, etc., can solve the problems of reactive dyes with special requirements, unable to dye with Shihlin dyes, and expensive equipment investment. , to save the bottoming and drying process, reduce the amount of salt, and reduce equipment investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

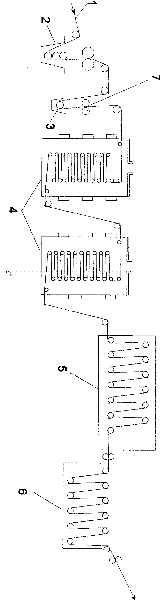

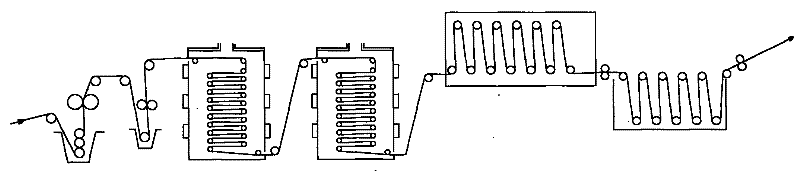

[0028] exist Figure 1 Among them, cloth (1) is pad-rolled reactive dyestuff in rolling groove (2) of even padding car, and the excess rate of rolling is about 60%, then enters small-capacity rolling alkali groove (3) and pads color-fixing alkali agent, through rolling car (7 ) to roll and fix the color alkali agent, and then enter the controllable moisture content dryer (4), and dry until the moisture content is below 30%. This moisture content can be set according to the process, and then enter the steam box (5 ) to carry out steaming and color fixation, the steaming temperature is 102°C, and then enter the washing tank for washing, soaping, washing and drying to complete the dyeing process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com