Directional reflective ceramic wafer

A ceramic sheet, reflective technology, applied in the directions of roads, road signs, traffic signals, etc., can solve the problems of inappropriate height, blackening of marking lines, friction and falling off, etc., to prevent sludge deposition, reduce bumps, and facilitate maintenance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

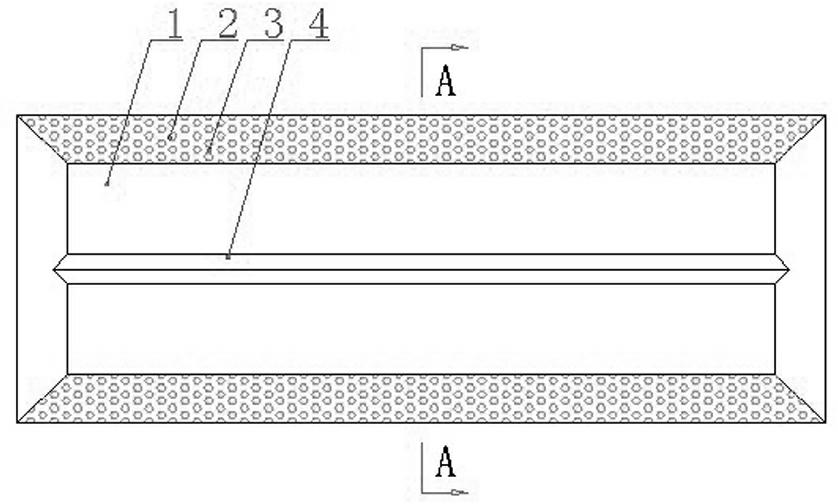

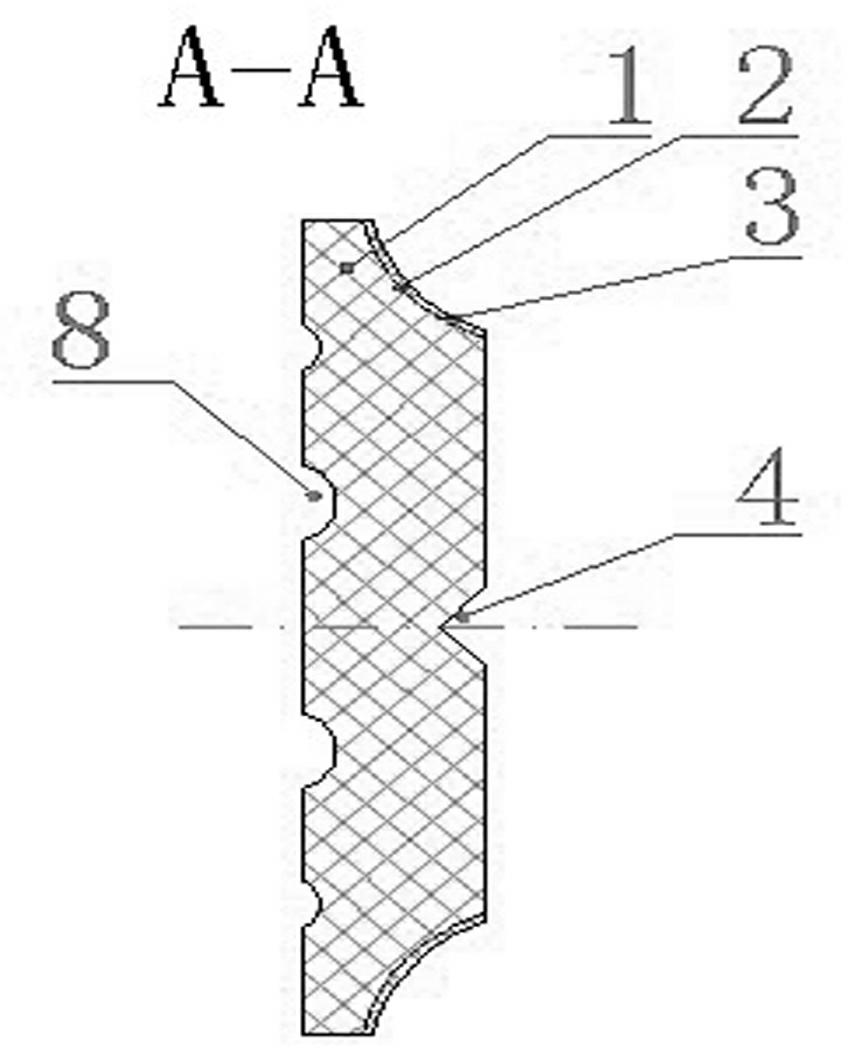

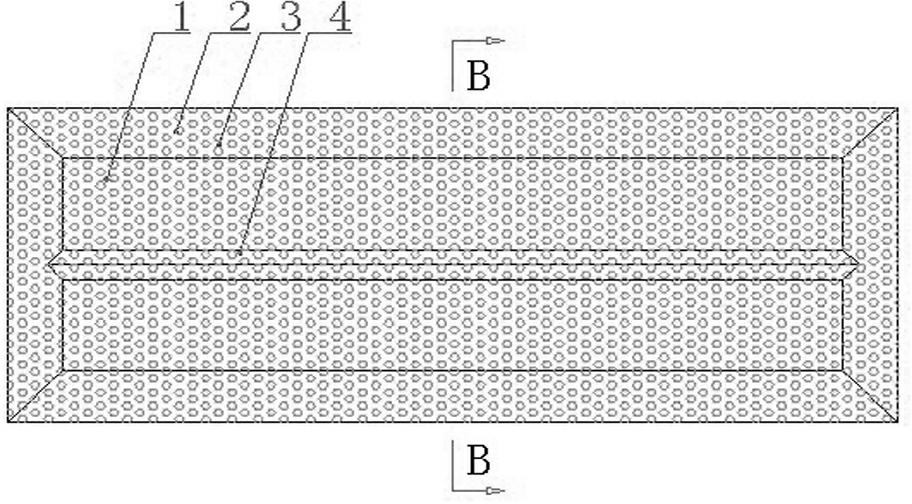

[0039] see Figure 1 to Figure 8 , a directional reflective ceramic sheet of the present invention, the common structure includes a ceramic sheet main body 1, a slope is provided around the top surface of the main body 1, and several grooves 8 are provided on the bottom surface of the main body 1. The thickness of the main body 1 is 7.5-12-15mm.

[0040] see figure 1 and figure 2 , The first embodiment: the slope is a concave arc-shaped slope 2; on the concave curved slope 2 on the upper and lower sides of the top surface of the main body 1, evenly distributed glass beads 3 are connected by an adhesive layer. An anti-skid groove 4 is provided in the middle of the top surface of the main body 1 . The area of the concave arc-shaped inclined surface 2 is about 1 / 4 of the sum of the areas of the top surface and the inclined surface of the main body 1 .

[0041] see image 3 and Figure 4, the second embodiment: the inclined surface is a concave arc inclined surface 2; the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com