Ultrasonic leakage detector for gas exhaust pipe for coal mine

A gas drainage and ultrasonic technology, applied in the pipeline system, mechanical equipment, gas/liquid distribution and storage, etc., can solve the problems of easy friction sparks, steel pipes are easy to corrode, and installation efficiency is low, so as to facilitate on-site inspection and use Convenience, fast results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings; it should be understood that the preferred embodiments are only for illustrating the present invention, rather than limiting the protection scope of the present invention.

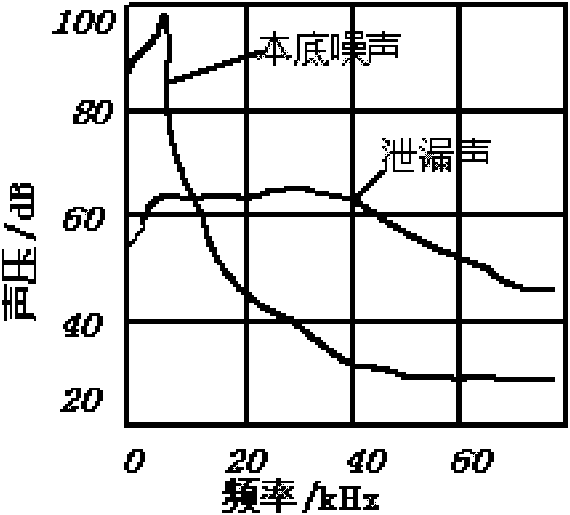

[0025] figure 1 It is the background noise and leakage sound sound pressure diagram, as shown in the figure, the principle of acoustic wave detection is: when the liquid in the pipeline leaks, due to the pressure difference between the inside and outside of the pipeline, the liquid in the pipeline will be squeezed when it passes through the leakage point and reaches the outside of the pipeline. Instead, a vortex is formed, which produces an oscillatingly varying pressure wave or sound wave. The sound waves generated by leakage have a wide frequency spectrum, usually distributed between 6-80KHz. Acoustic wave detection is to use the noise generated by leakage as the sign...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com