Lamp post made of composite material

A technology of composite materials and street light poles, which is applied in the direction of lighting devices, lighting device parts, lighting auxiliary devices, etc., can solve the problems of difficult promotion and high production cost, and achieve the effect of cheap manufacturing cost, low manufacturing cost and beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

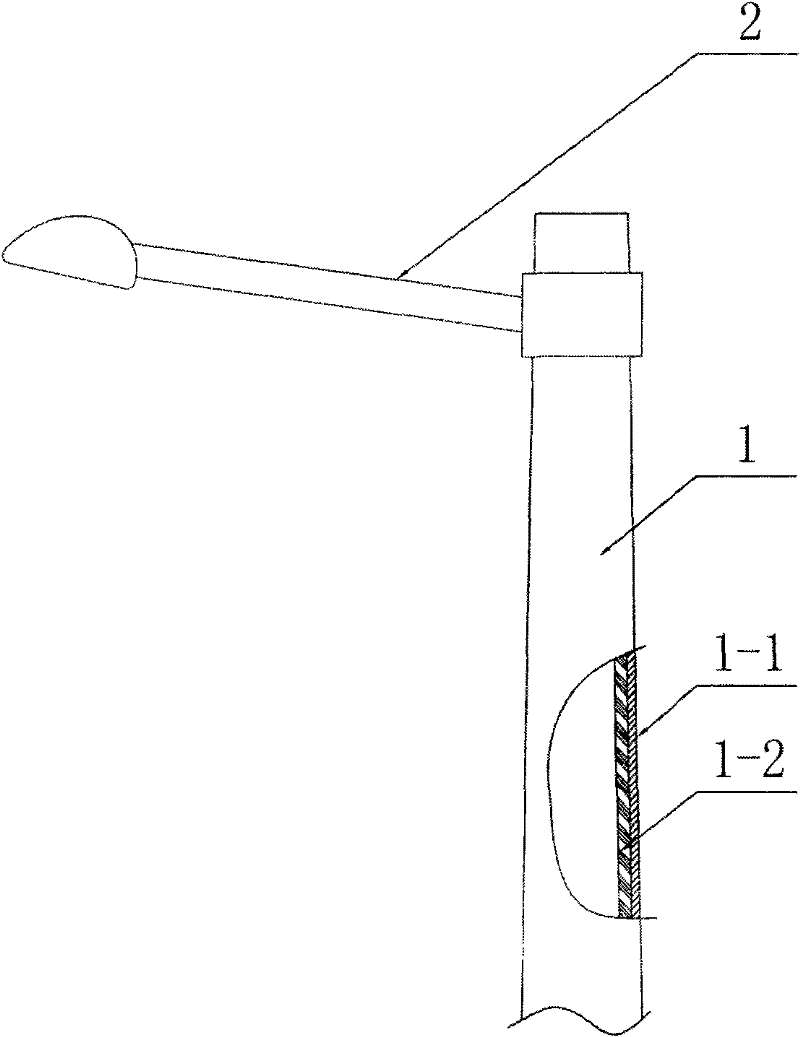

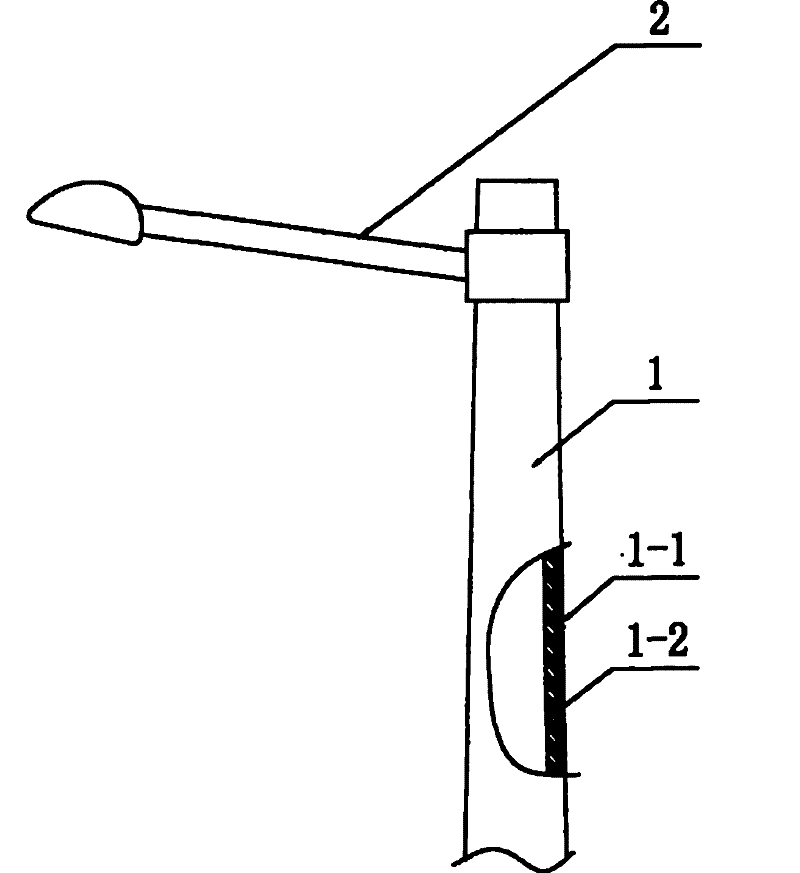

[0015] As shown in the figure, a composite material street light pole has a shaft and a pole arm. The shaft [1] is composed of an outer wall layer [1-1] and an inner core layer [1-2]. The outer wall layer [1-1] It is composed of continuous glass fiber reinforced unsaturated resin, and 82% of the fibers are axially distributed; the inner core layer [1-2] is composed of 28% unsaturated resin, 15% short glass fiber, 25% 400 mesh talc powder, 32% of 10-80 mesh quartz sand; the lever arm [2] is composed of continuous glass fiber reinforced unsaturated resin.

Embodiment 2

[0017] As shown in the figure, a composite material street light pole has a shaft and a pole arm. The shaft [1] is composed of an outer wall layer [1-1] and an inner core layer [1-2]. The outer wall layer [1-1] It is composed of continuous basalt fiber reinforced unsaturated resin, and 88% of the fibers are axially distributed; the inner core layer [1-2] is composed of 22% unsaturated resin, 5% short glass fiber, 40% river Sand, 15% feldspar powder, 18% quartz powder; the rod arm [2] is composed of continuous basalt fiber reinforced unsaturated polyester.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com