Process for producing coarse grain instant food

A technology of convenience food and production technology, applied in food preparation, food science, application, etc., can solve the problems of reduced nutritional value of protein, indigestion, and nutrient destruction, and achieve the effects of easy digestion and absorption, extended shelf life, and less heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

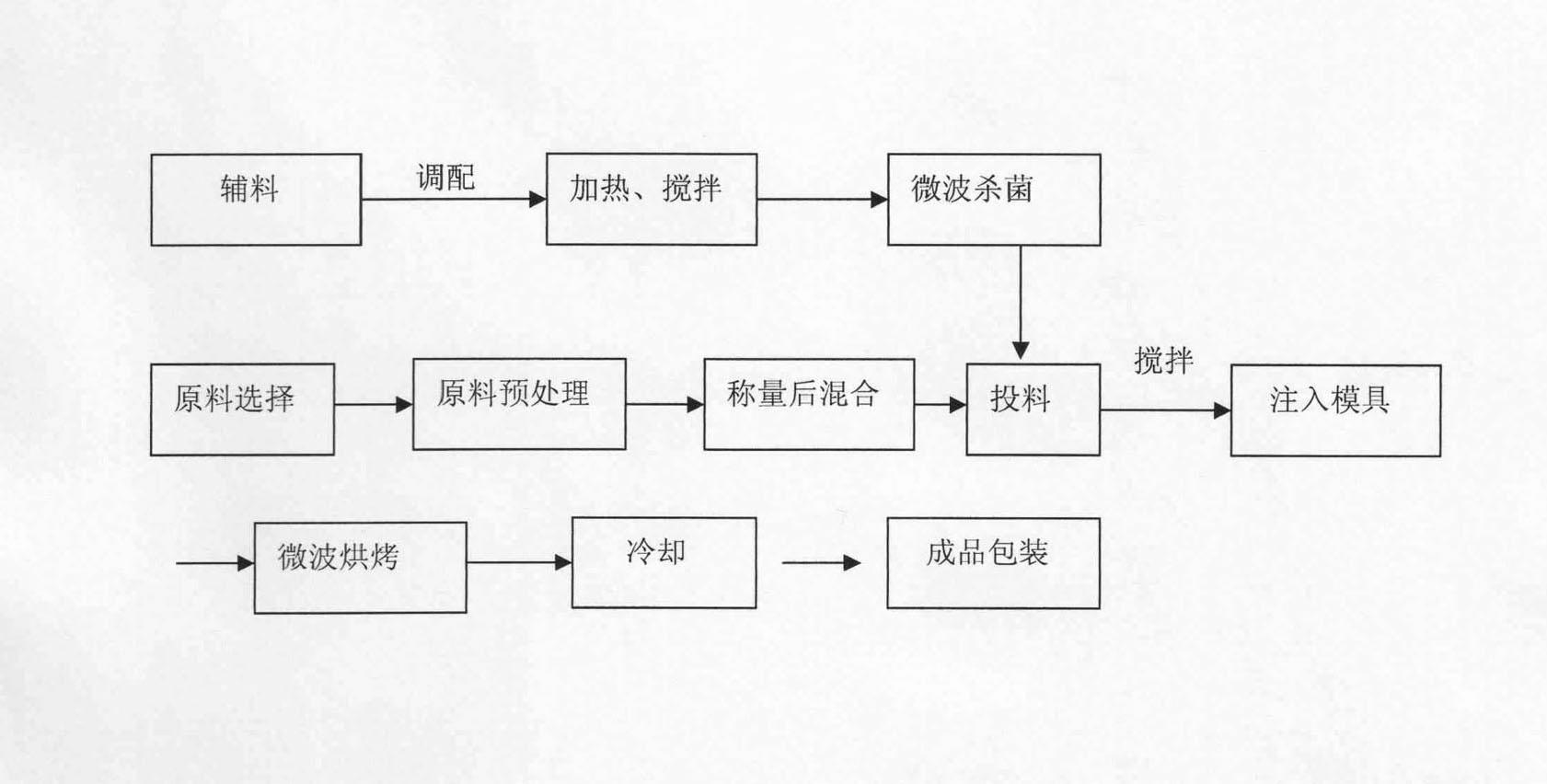

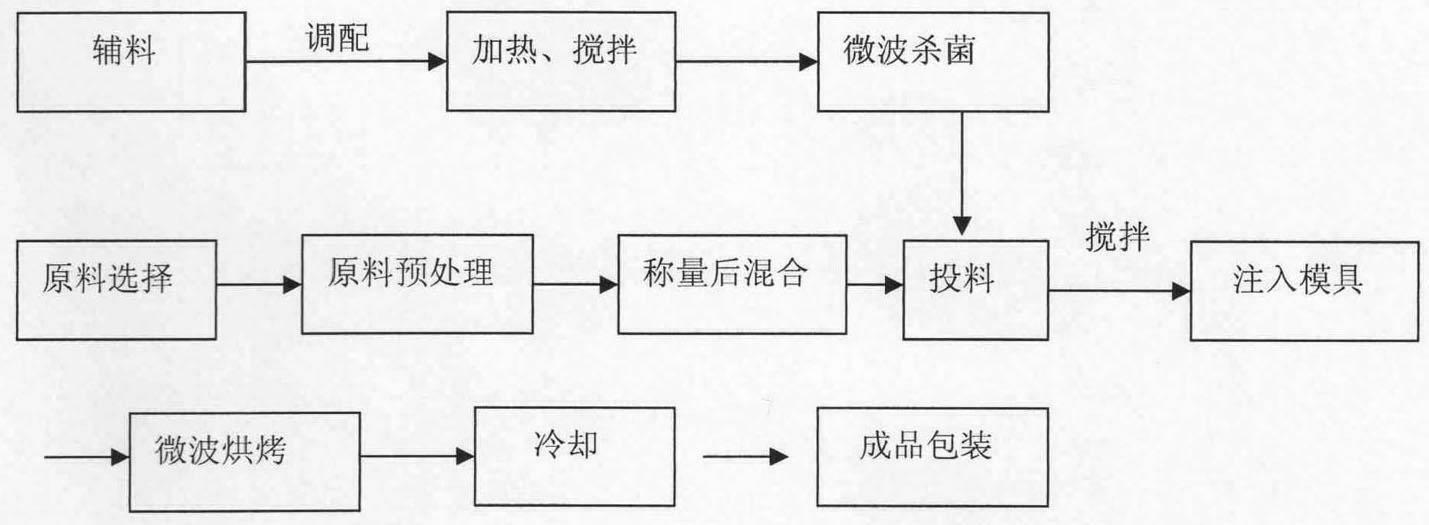

Image

Examples

Embodiment 1

[0025] Embodiment 1: body sculpting coarse grain bar

[0026] 38% oatmeal, 2.23% orange peel, 7.6% raisins, 4.3% dried apples, 10.8% almonds, 5.4% peanuts, 17.3% maltitol, 6.5% white sugar, 3.2% honey, 3.2% soybean oil, 0.43% soybean lecithin , sodium bicarbonate 0.22%, edible salt 0.5%, xylitol 0.17%, antioxidants BHA, BHT 0.02%, food flavor 0.13%.

Embodiment 2

[0027] Example 2: Sugar-free whole grain bar

[0028] Oatmeal 34.2%, sunflower kernels 1.9%, peanut kernels 12.3%, dried apples 4.75%, raisins 9.5%, almonds 3.84%, soybean flour 2.8%, walnut kernels 0.9%, maltodextrin 0.5%, soybean lecithin 0.4%, Edible salt 0.2%, maltitol 23.7%, honey 2.8%, soybean oil 1.9%, sodium bicarbonate 0.09%, xylitol 0.2%, antioxidants BHA, BHT 0.02%.

Embodiment 3

[0029] Example 3: Nutritional Coarse Grain Bar

[0030] Oatmeal 33.9%, red dates 5.8%, wolfberry 1.94%, dried apples 5.8%, raisins 7.7%, longan meat 1.9%, almonds 9.7%, peanut kernels 4.8%, maltitol 15.5%, white sugar 5.8%, honey 2.9%, Soybean oil 2.9%, soybean lecithin 0.4%, edible salt 0.48%, sodium bicarbonate 0.19%, xylitol 0.15%, antioxidants BHA, BHT 0.02%, food flavor 0.12%.

[0031] The production process of the above-mentioned coarse grain bar is: firstly, the auxiliary materials maltitol, white granulated sugar, soybean oil, honey, xylitol and various food additives are prepared according to the formula ratio, and heated in a vertical mixer at a temperature of 100-105°C for about 10 Minutes, stirring while heating, continuous stirring for 30 minutes, enter the microwave sterilization for about 10 minutes; at the same time, the main ingredients oatmeal, nuts, and dried fruits are pretreated, and the nuts and dried fruits are selected and cleaned. The nuts and large p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com