Smelting method of axle steel for high-speed motor car

A technology for axle steel and smelting methods, which is applied to the improvement of process efficiency, furnace type, furnace, etc., and can solve the problems that the control level of inclusions cannot meet the requirements for high-speed axle use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

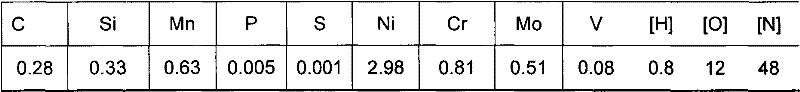

[0029] The mass percentage of the components of the pretreated molten iron used in this embodiment is:

[0030] C 4.05%; Si 0.43%; S 0.006%%; P 0.060%

[0031] The rest is Fe and unavoidable impurities, the temperature of molten iron is 1350℃;

[0032] The scrap steel used is the cut head and tail material of the company's internal medium carbon steel, with P 0.012% and S 0.008% in the scrap;

[0033] The specific steps of this embodiment are as follows:

[0034] At 11:10, first add 5.6 tons of scrap steel into the EBT electric furnace.

[0035] At 11:12, 62.4 tons of molten iron are added to the EBT electric furnace.

[0036] 11:25 Top blow oxygen to melt.

[0037] 11:35 After blowing oxygen for 10 minutes, add 1500kg lime, a slag-making material, to make foam slag, reduce carbon and phosphorus.

[0038] 11:53 The temperature of molten steel during melting is 1642℃, the chemical composition of melting:

[0039] C = 0.76%, Si = 0.01%, Mn = 0.12%, P = 0.011%, S = 0.031%, Ni = 0.020%,

[0040] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com