Micro-stress assembly flexible supporting method of small-calibre micro-crystal glass material reflector

A technology of glass-ceramics and flexible support, applied in installation, optics, instruments, etc., can solve problems such as field curvature, astigmatism, heavy weight, and complex structure, and achieve high positioning accuracy, light weight, and good vibration reduction performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

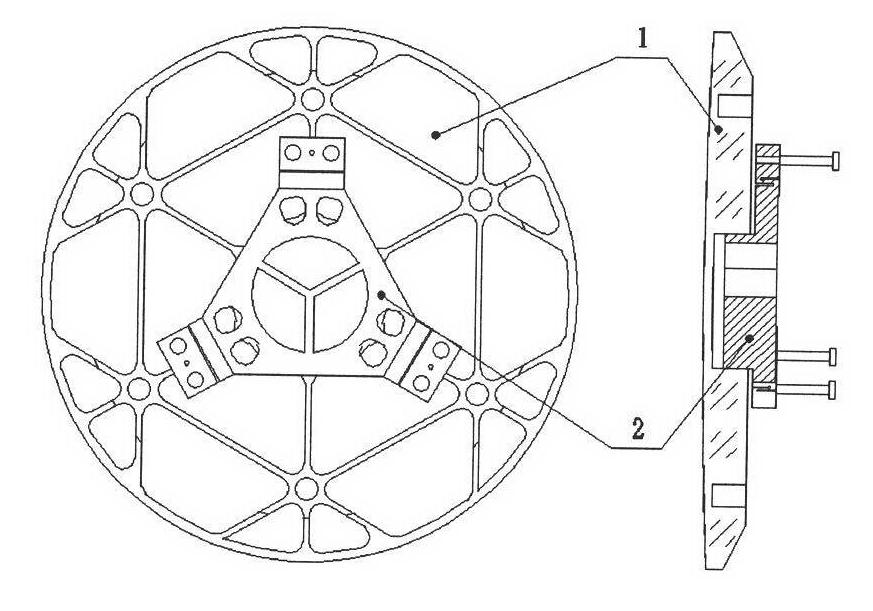

[0022] Such as figure 1 As shown, it is a schematic diagram of the support structure of the reflector supported by the method of the present invention. The main steps of the micro-stress assembly flexible support method of the reflector of the present invention are as follows:

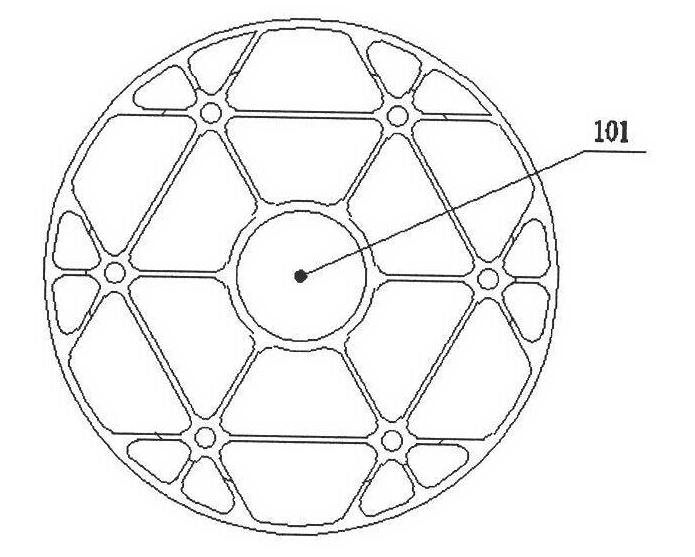

[0023] (1) if figure 2 As shown, lightweight processing is carried out on the back of the reflector 1, and the lightweight form can be composed of regular figures such as triangles, quadrilaterals, hexagons and circles (triangles, quadrilaterals and circles are used as lightweight forms in the accompanying drawings), The central column 101 is a mounting hole, and the inner surface needs to be ground to ensure its cylindricity and thus ensure bonding accuracy and bonding reliability;

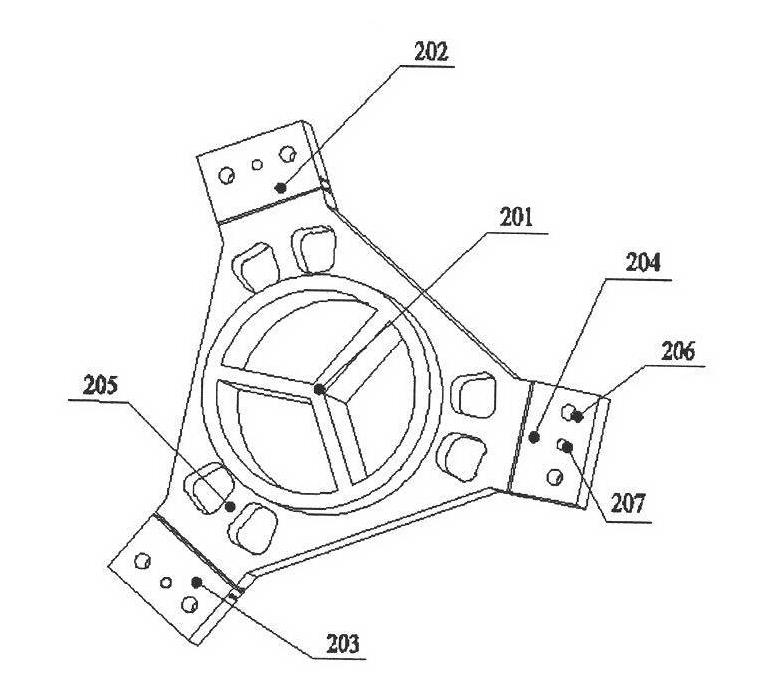

[0024] (2) if image 3 and Figure 4 As shown, the flexible mandrel 2 is an equilateral triangular structure, a hollow cylinder 201 is processed in the middle, and a connecting part 202-204 of cuboid structure is proc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com