Quartz heating groove

A quartz heating and quartz technology, applied in heating elements, water heaters, fluid heaters, etc., can solve the problems of poor heat preservation effect, rapid temperature drop of quartz heating tank, waste of electric energy, etc., and achieve the effect of ensuring heat preservation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

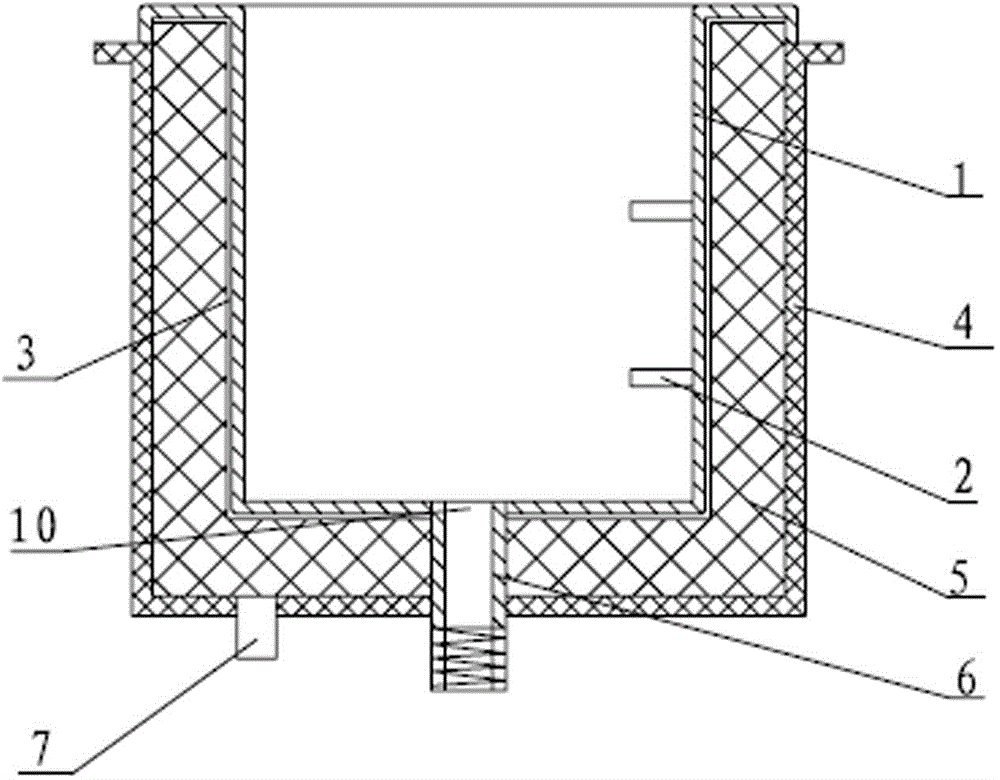

[0011] Such as figure 1 As shown, the quartz heating tank according to this embodiment includes a quartz tank body 1, a thermocouple protection tube 2 arranged in the quartz tank body 1, a heating resistance wire 3 attached to the outer surface of the quartz tank body 1, and a heating resistance wire 3 arranged on the outer surface of the quartz tank body 1. The PP plastic layer 4 around the wire 3 and the quartz wool layer 5 filled between the heating resistance wire 3 and the PP plastic layer 4 . A drain port 10 is provided at the middle of the bottom of the quartz tank body 1 , and the quartz heating tank also includes a drain pipe 6 passing through the PP plastic layer 4 , the quartz wool layer 5 and the heating resistance wire 3 to communicate with the drain port 10 . In addition, a wire outlet 7 is also provided on the PP plastic layer 4 . The heating resistance wire 3 is made of nickel-chromium wire.

[0012] In the heating tank of the present invention, a heatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com