Method for purifying high-purity pemetrexed disodium

A technology of pemetrexed disodium and purification method, which is applied in the field of pharmaceutical manufacturing, can solve the problems of inability to effectively remove various impurities and degrade impurities, and achieve the effects of low cost, easy industrialization, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

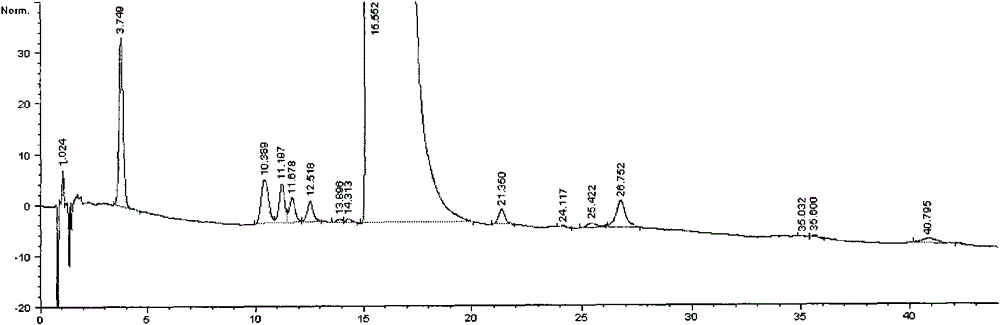

Embodiment 1

[0063] Weigh 20 g of pemetrexed disodium raw material 1 (content 98.86%) and add 8 times the amount of water to dissolve at room temperature, add 25% sodium chloride solution to make the concentration of sodium chloride reach 12%, stir, and place for crystallization for 2 hours. Filter, wash the filter cake with 12% sodium chloride solution, drain it, add 15 times the amount of water to dissolve the filter cake, add 95% ethanol to make the alcohol content reach 80%, and place it for 2 hours to crystallize after stirring. After filtering, the filter cake was washed with 80% ethanol, sucked dry, and dried under reduced pressure to obtain pemetrexed disodium.

Embodiment 2

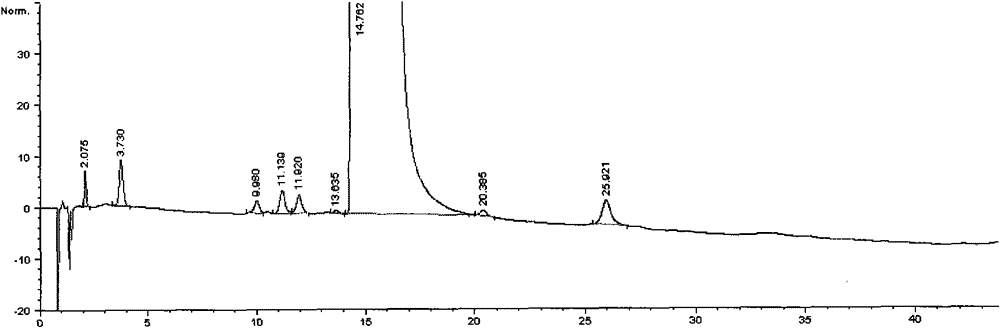

[0065] Dissolve the wet product before drying under reduced pressure in Example 1 with 15 times the amount of water at room temperature, add 25% sodium chloride solution to make the concentration of sodium chloride reach 12%, stir, crystallize and place for 2 hours, filter, filter cake with 12 Wash the filter cake with 15% sodium chloride solution, drain it, add 15 times the amount of water to dissolve it, add 95% ethanol to make the alcohol content reach 80%, and place it for 2 hours to crystallize after stirring. After filtering, the filter cake was washed with 80% ethanol, sucked dry, and dried under reduced pressure to obtain pemetrexed disodium.

Embodiment 3

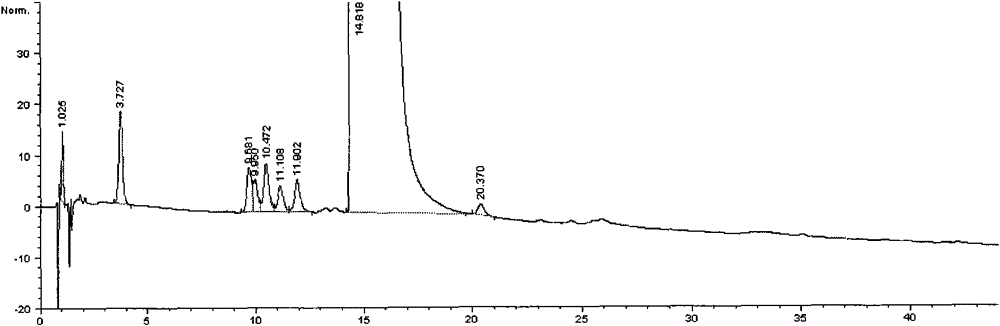

[0067] Weigh 20 g of pemetrexed disodium raw material 1 (content 98.86%) and add 8 times the amount of water to dissolve at room temperature, add 25% sodium chloride solution to make the concentration of sodium chloride reach 10%, stir, and place for crystallization for 2 hours, Filter, wash the filter cake with 10% sodium chloride solution, drain it, add 15 times the amount of water to dissolve the filter cake, add 95% ethanol to make the alcohol content reach 75%, and place it for 2 hours to crystallize. After filtering, the filter cake was washed with 75% ethanol, sucked dry, and dried under reduced pressure to obtain pemetrexed disodium.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com