System and method for preparing nosiheptide premix particles

A technology of nosiheptide and premix, applied in the field of biopharmaceuticals, can solve the problems of complicated process, high cost, dust generation, etc., and achieve the effects of simple production process, no dust pollution and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

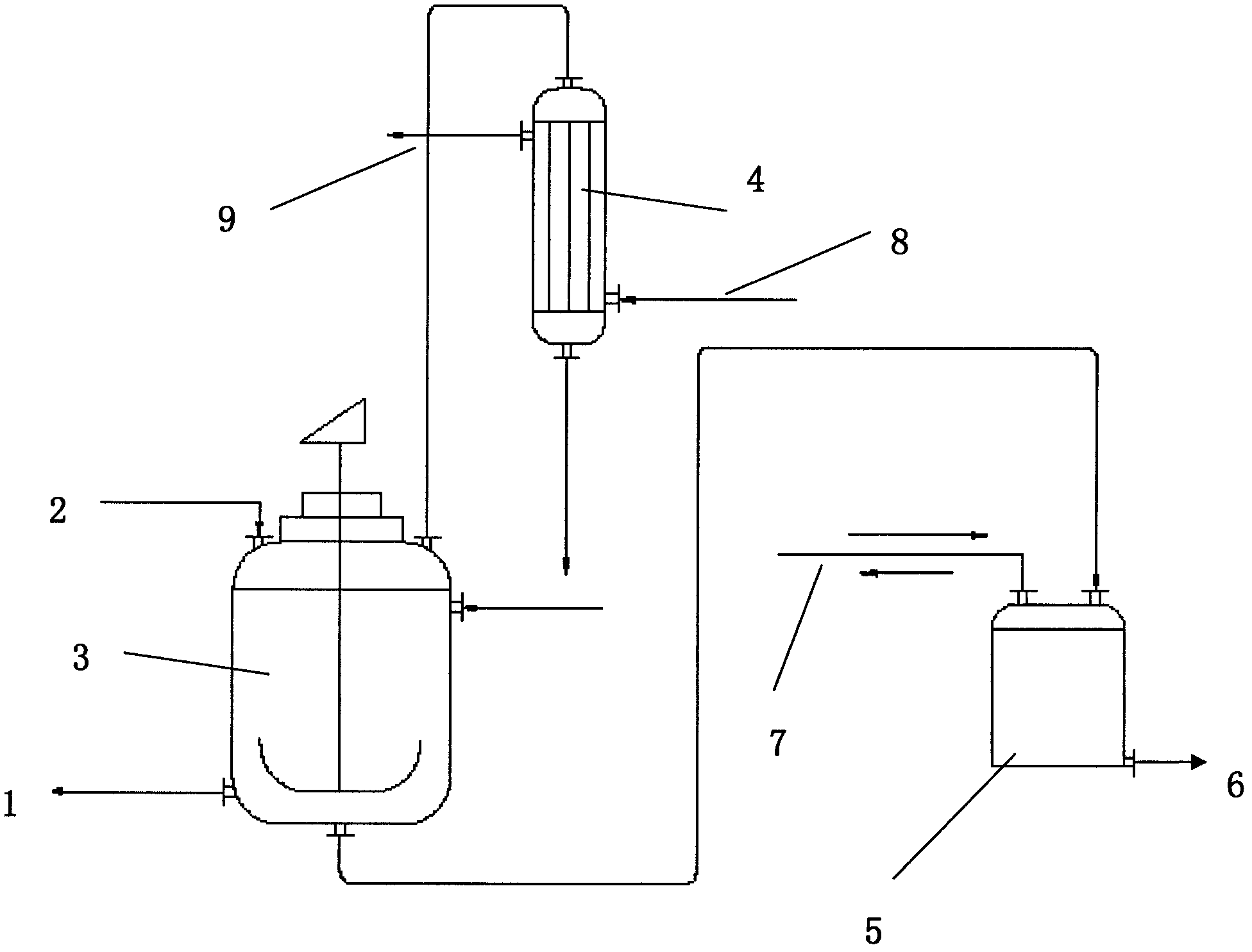

Method used

Image

Examples

Embodiment 1

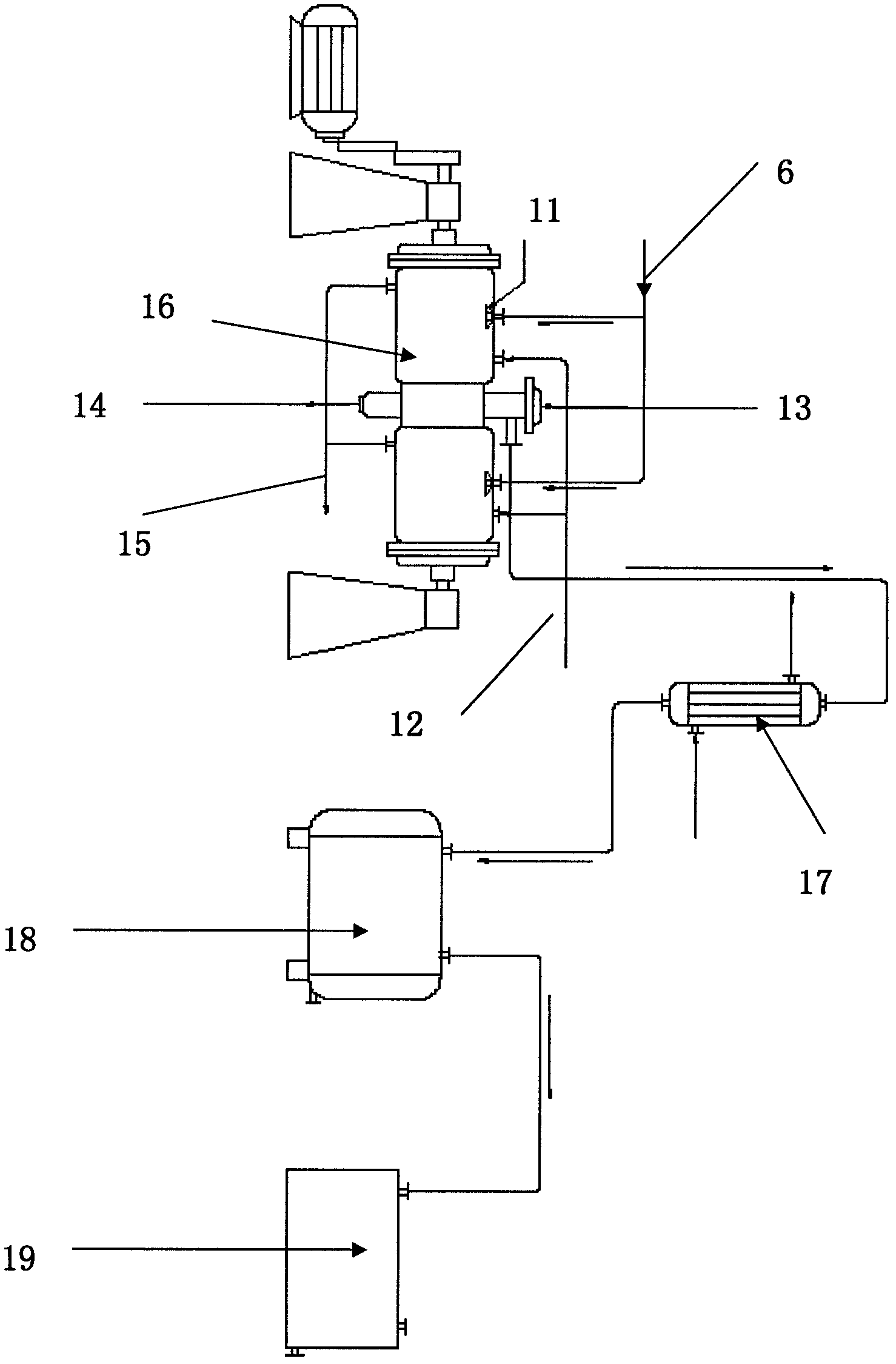

[0035]After the nosiheptide fermentation was terminated, the fermented liquid was input into the reaction pot (Hangzhou West Lake Glass-lined Equipment Co., Ltd., model: K2000) through the pipeline, and the temperature was raised while stirring. The stirring speed was 80 rpm, and the temperature was set at 100 ℃, remove about 20% of the moisture, the temperature is lowered to normal temperature, and the content of Nosiheptide is measured to be 13.18mg / ml, then the vacuum pump 7 with a pressure of 0.08MPa will pump the 100L Nosiheptide concentrated solution into the fermentation broth storage tank 5 (Hangzhou Xin'anjiang Industrial Pump Co., Ltd., model: RB-65-280), add 0.2 kg of sodium hydroxymethyl cellulose, and use a stirring paddle (Hangzhou West Lake Glass-Lined Equipment Co., Ltd., anchor type) with a speed of 25 rpm BXH k1000) was stirred for 8 minutes; the corncob powder 520.7kg of 40 orders (0.42mm) was dropped into the vacuum rake dryer 16 (Hangzhou Qianjiang Drying E...

Embodiment 2

[0037] The same device name is the same as the manufacturer and model in Example 1.

[0038] After the termination of Nosiheptide fermentation, use a centrifuge (Zhangjiagang Shengfeng Pharmaceutical Machinery Factory, model: SB1000) to carry out centrifugation, remove about 25% of the water, measure the content of Nosiheptide to be 14.11mg / ml, and then use a pressure of 0.09 MPa vacuum pump pumps 200L nosiheptide concentrated solution into the storage tank, adds 0.05kg xanthan gum, and uses a stirring blade with a speed of 30 rpm to stir for 8 minutes; the soybean meal 551.4 kg into the vacuum rake dryer, close the feeding port; use an air compressor to transport the nosiheptide concentrate that is uniformly mixed with the binder in the storage tank to the vacuum rake dryer through a pipeline under a pressure of 0.6MPa. And evenly sprayed on the carrier, when the mixture is sprayed, the carrier rotates at a speed of 5 revolutions per minute in the vacuum rake dryer; after the...

Embodiment 3

[0040] After nosiheptide fermentation was terminated, the fermented liquid was filtered through a metal membrane (Hefei Fengyun Membrane Separation Technology Co., Ltd.), and about 30% of the moisture was removed. It was measured that the content of nosiheptide was 15.17mg / ml, and then the pressure was 0.09MPa Vacuum pump pumps 400L nosiheptide concentrate into the storage tank, add 0.1kg β-cyclodextrin, and use a stirring paddle with a speed of 30 rpm to stir for 10 minutes; 580.8 kg into the vacuum rake dryer, close the feeding port; use an air compressor to transport the nosiheptide concentrate that is uniformly mixed with the binder in the storage tank to the vacuum rake dryer through a pipeline under a pressure of 0.6MPa. And evenly sprayed on the carrier, when the mixture is sprayed, the carrier rotates at a speed of 5 revolutions per minute in the vacuum rake dryer; after the mixture is conveyed, the vacuum rake dryer is sealed, the temperature starts to rise, and the te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com