Composite moisture absorption material based on carbon base and calcium chloride and preparation method thereof

A technology for hygroscopic materials and carbon-based materials, which is applied in chemical instruments and methods, separation methods, and other chemical processes, etc., can solve the problems of loss of hygroscopic agent, poor hygroscopic effect, and low adsorption capacity, and achieves low cost and stable physicochemical properties. , the effect of increasing the specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

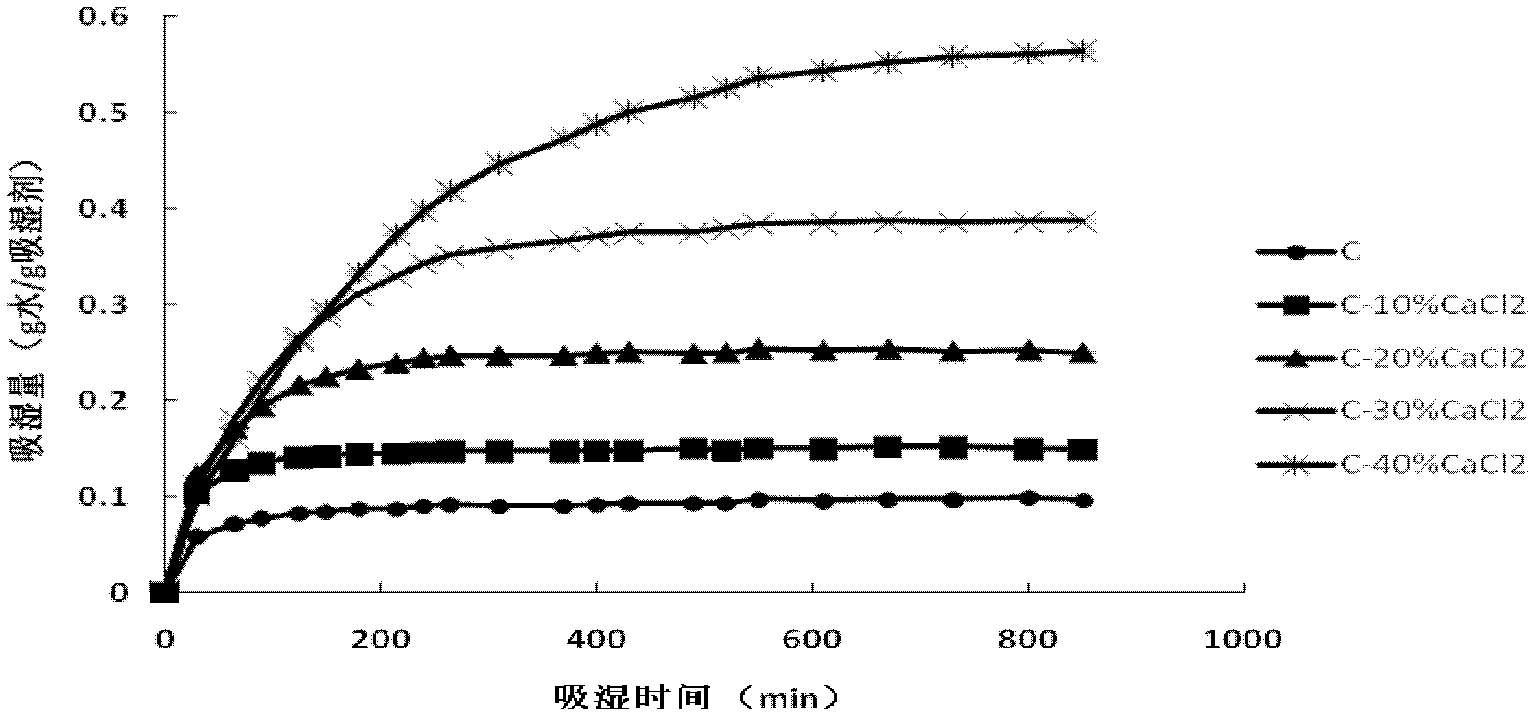

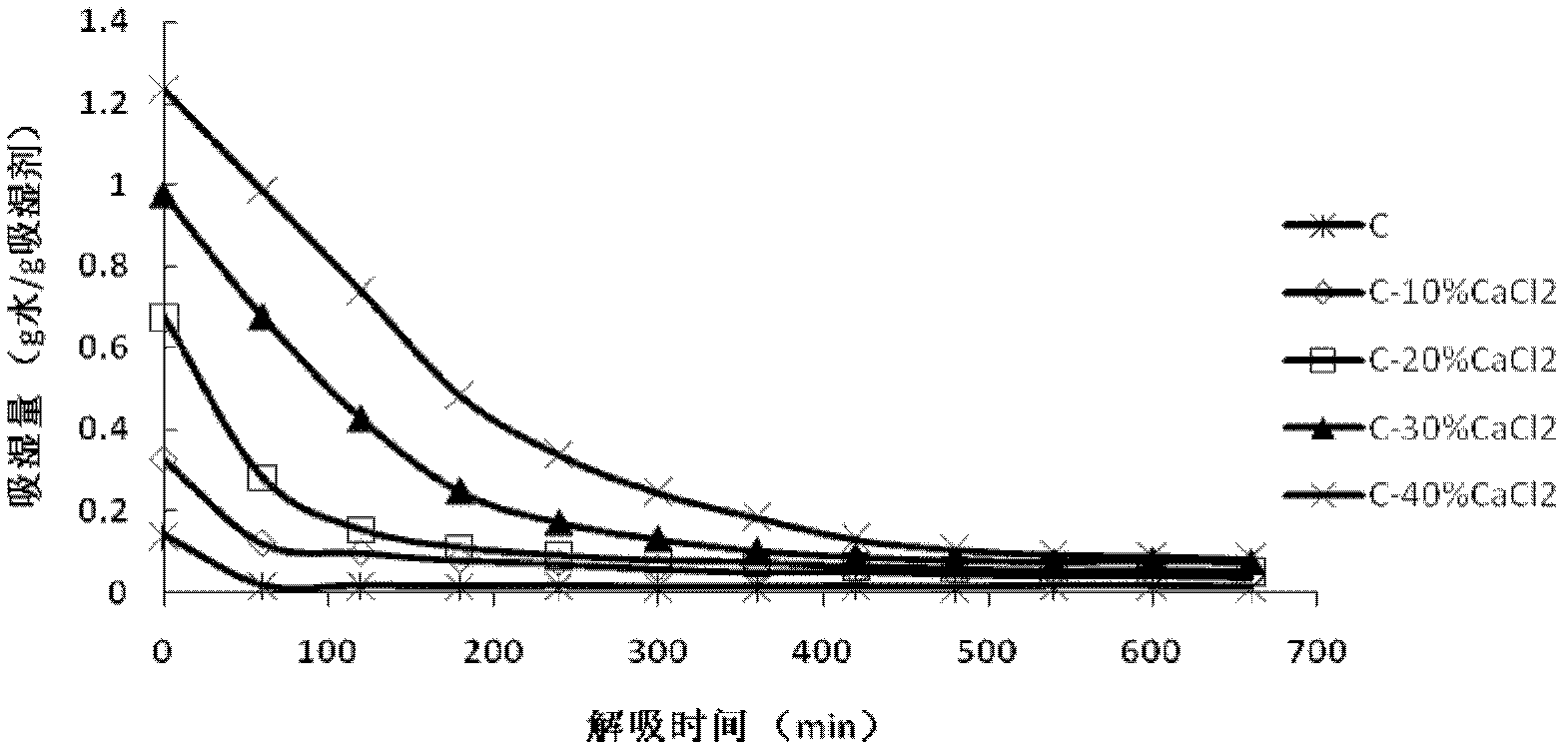

[0024] Activated carbon granular carbon base (specific surface area is 500m 2 / g, the bulk density is 0.5g / cm 3 , particle size is 4 orders), and 10%, 20%, 30%, the calcium chloride solution soaking of 40% mass concentration, the mass ratio of activated carbon granular carbon base and calcium chloride is 36: 31, and soaking time is 12 hours, Soaking condition is normal temperature 25 ℃, isolated from air. The soaked solid mixture was filtered and put into a constant temperature drying oven to dry for 12 hours under a drying condition of 120°C. Composite hygroscopic materials with different calcium chloride contents are thus prepared.

[0025] Under the following conditions: set the temperature of the constant temperature and humidity test box to 20°C, and the relative humidity to 50%. After the temperature and humidity in the box are stabilized, various hygroscopic materials prepared by combining activated carbon and calcium chloride are put into the box. Within a certain p...

Embodiment 2

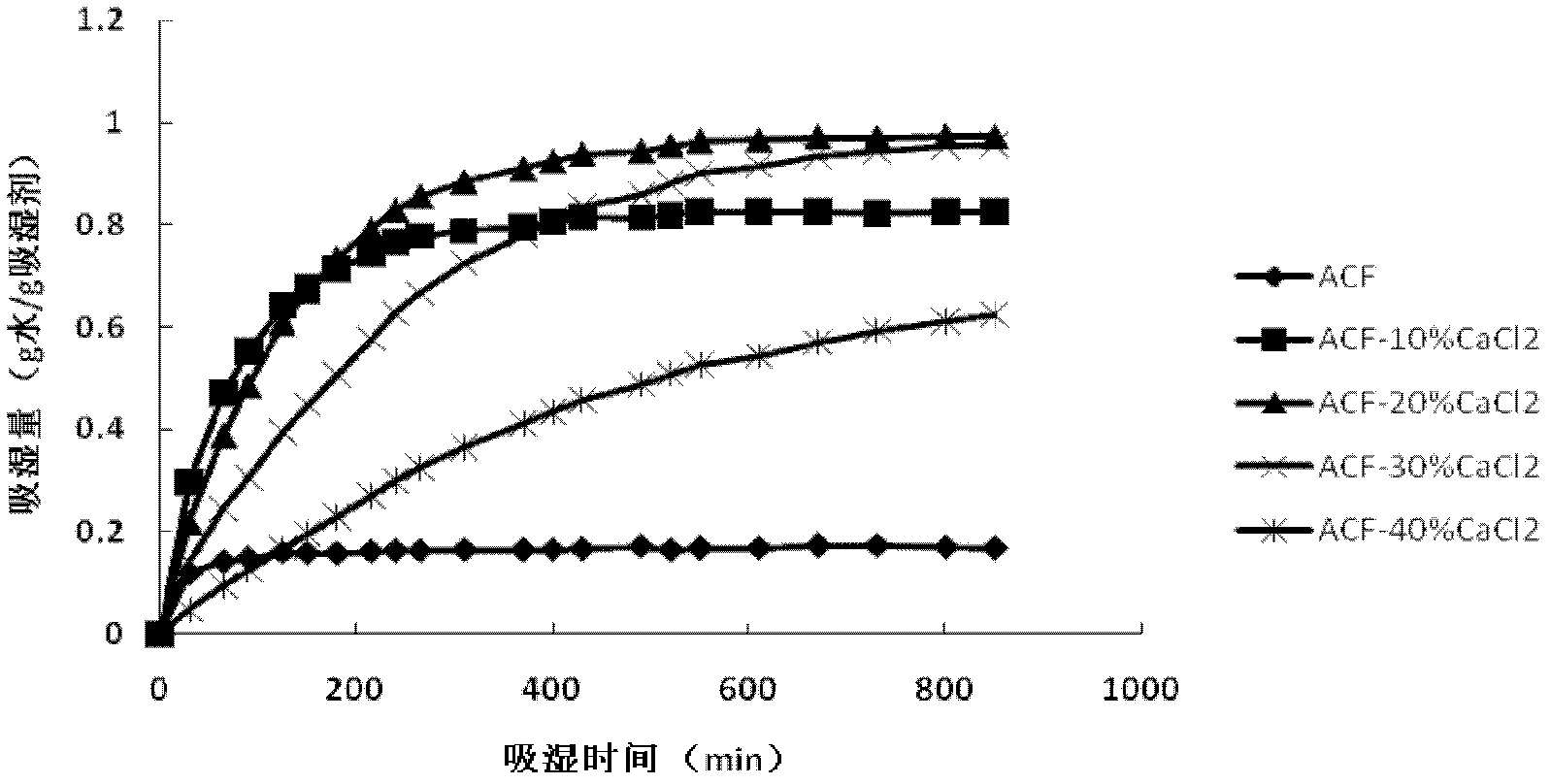

[0029] Activated carbon fiber carbon base (specific surface area is 1000m 2 / g), with 10%, 20%, 30%, the calcium chloride solution soaking of 40% mass concentration, the mass ratio of activated carbon fiber carbon base and calcium chloride is 13: 40, and soaking time is 12 hours, and soaking condition is Room temperature 25°C, isolated from air. The soaked solid mixture was filtered and put into a constant temperature drying oven to dry for 12 hours under a drying condition of 120°C. Composite hygroscopic materials with different calcium chloride contents are thus prepared.

[0030] Under the following conditions: set the temperature of the constant temperature and humidity test box to 20°C, and the relative humidity to 50%. After the temperature and humidity in the box are stabilized, various hygroscopic materials prepared by combining activated carbon and calcium chloride are put into the box. Within a certain period of time, the weight of the hygroscopic agent is measured...

Embodiment 3

[0034] Activated carbon granular carbon base (the specific surface area of activated carbon particles is 600m 2 / g, the bulk density is 0.6g / cm 3 , particle size is 10 orders), and 10%, 20%, 30%, the calcium chloride solution soaking of 40% mass concentration, the mass ratio of activated carbon granular carbon base and calcium chloride is 15: 1, and soaking time is 24 hours, Soaking condition is normal temperature 25 ℃, isolated from air. Filter the solid mixture after soaking, and put it into a constant temperature drying oven to dry for 24 hours under the drying condition of 140°C. Composite hygroscopic materials with different calcium chloride contents are thus prepared.

[0035] The temperature of the constant temperature and humidity test chamber is set at 20°C, and the relative humidity is 30%, 40%, 50%, 60%, 70%, 80%, and 90%. Measure the equilibrium moisture absorption of activated carbon-calcium chloride composite hygroscopic material at various relative humidity...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com