Constant temperature ink conveyer

A technology of ink delivery and constant temperature, which is applied in the direction of printing, printing machines, general parts of printing machinery, etc. It can solve the problems of large changes in ink temperature and viscosity, difficult control of product printing quality, and large power consumption. And the viscosity is uniform and stable, the energy saving effect is remarkable, and the production efficiency is high.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

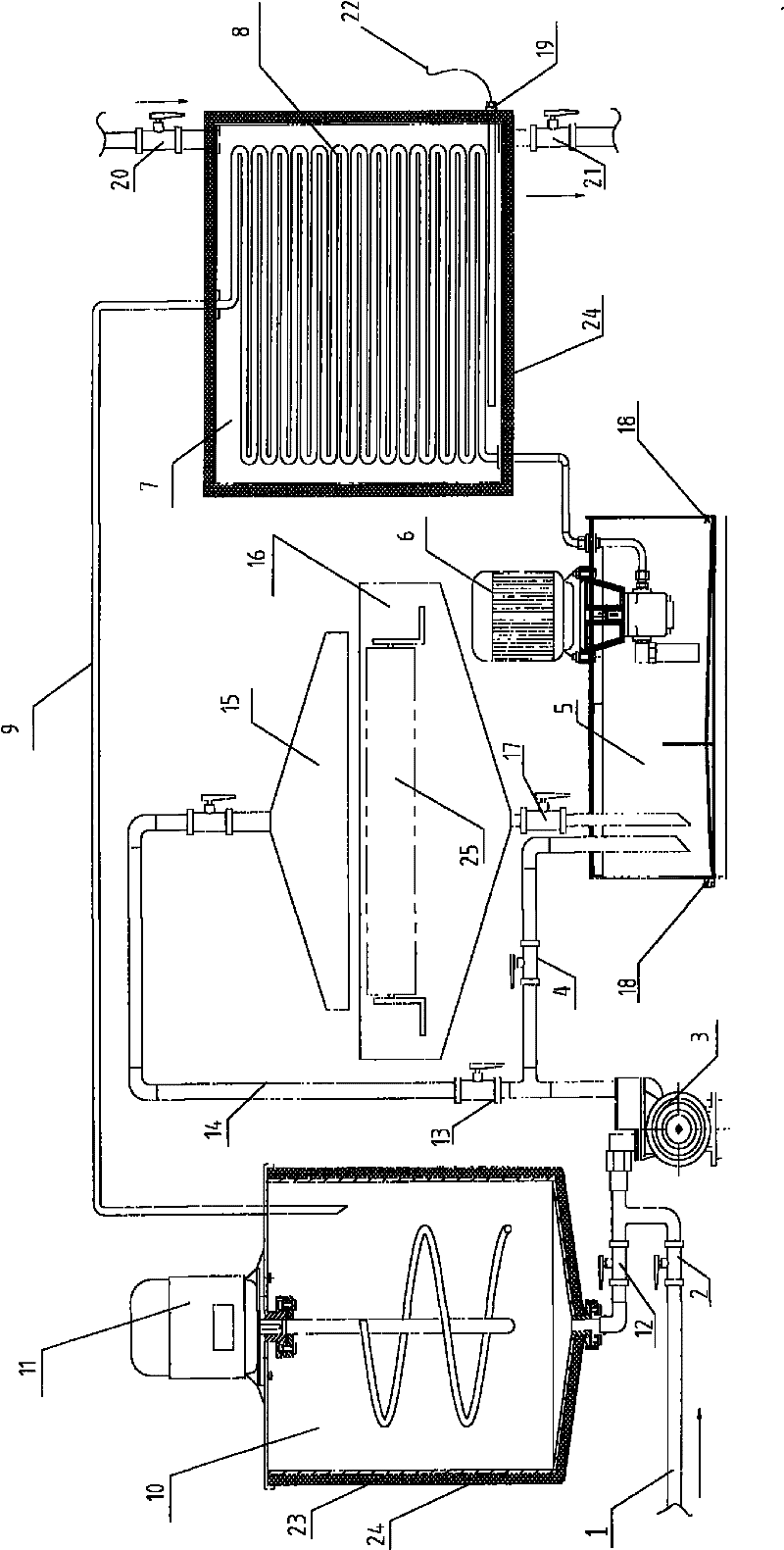

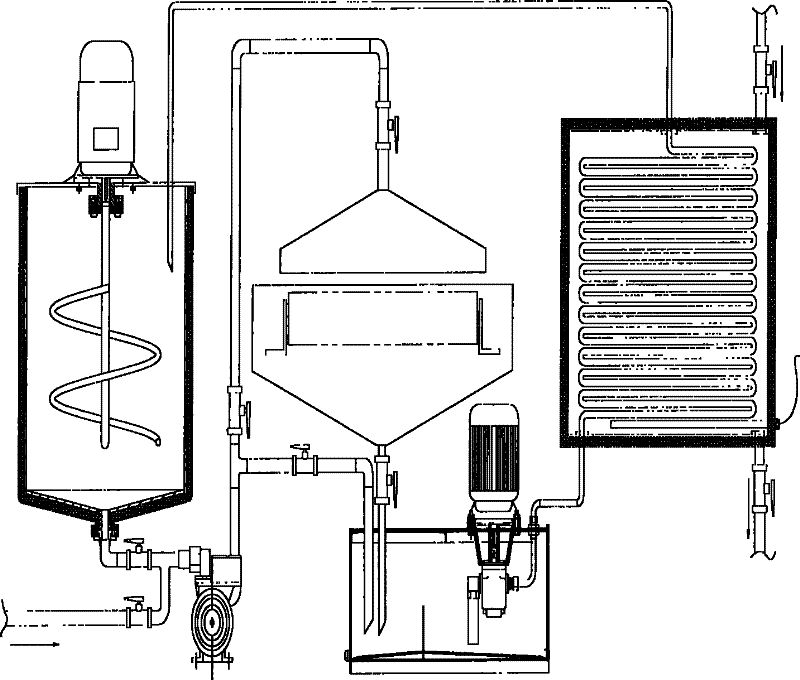

[0015] Fig. 1 is a schematic diagram of the system structure of the spiral constant temperature ink conveyer of the present invention. As shown in Figure 1, the production technology of the present invention can all be realized by conventional processing equipment, and its working principle is: ink enters from 1 ink input pipe through 2 ink input pipe valves, and passes through 4 valves under the effect of 3 ink pumps The pipeline is injected into the 5 ink recovery tank; under the action of the 6 ink delivery pump, the pipeline enters the 7 ink heat exchange tank; in the 7 ink heat exchange tank, heat exchange is performed through the 8 spiral heat exchange tube; when the ink reaches the required temperature , the ink reaches the 10 constant temperature tank through the 9 delivery pipe; in the 10 constant temperature tank, there are 11 stirrers stirring constantly, so that the temperature and viscosity of the ink can be evened; when the ink in the 10 constant temperature tank ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com